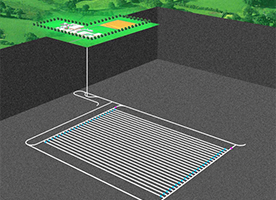

Developing new technologies to make use of underground space

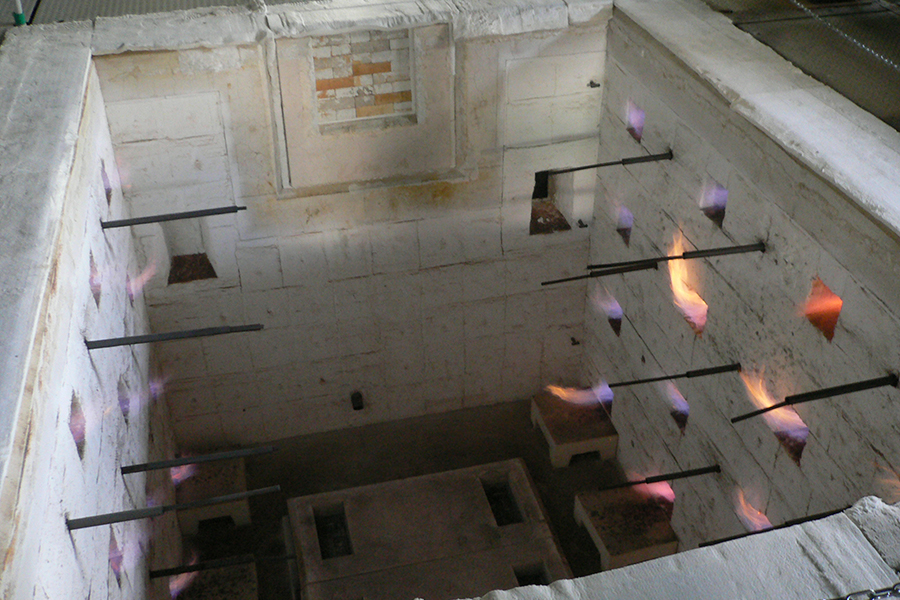

In the Rock Testing Block, we are working to develop new technologies for existing facilities such as tunnels and underground power generation plants. We also conduct research and development aimed at new underground facilities such as high level radioactive waste disposal sites. We use testing equipment having various different load-bearing capacities to test and evaluate the mechanical, hydraulic, and physical properties of rock and bedrock under many different conditions, such as high-pressure and high-temperature environment deep under the ground.

Types of Testing

- Triaxial compression test, triaxial creep test, fatigue test, bending test

- Triaxial compression test, permeability test, under high-pressure (80 MPa max.) and/or high-temperature (200℃ max.)

- Testing of various mock-ups using a combination of a load frame and hydraulic pressure generator

Facility Features

- 0.5 MN, and 4.6 MN load testing devices

- 80 MPa hydraulic pressure generators

- Triaxial compression testing machine for soft rock (in a thermostatic laboratory)

- Portable load testing machine

- Rock specimen molding equipment (surface grinder, cutter, boring machine)

Examples of Tests and Achievements

- Basic research to build a rock mechanics model presuming a large rock cavern

- Evaluation of strength and deformation characteristics of soft rock presumed urban underground

- Performance evaluation of fiber-reinforced concrete materials and woody materials

- Evaluation of mechanical properties of tunnel support members

- Evaluation of rock permeability at high level radioactive waste disposal sites