Shimizu Swing Mass Damper, Rooftop Damping Device

The Shimizu Swing Mass Damper (SMD) is a control device that is installed on the rooftop to control the complex shaking of ultra high-rise buildings due to long-period earthquake motion.

When the planar shape of a building is not perfectly square, the natural period of vibration for longer and shorter sides of the building differ. The conventional rooftop control devices can only match the period of the shaking in one direction, so they cannot sufficiently control the shaking.

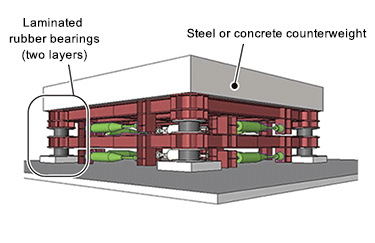

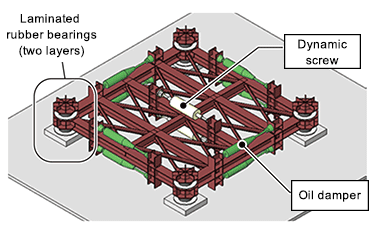

Shimizu’s SMD incorporates dynamic screws inside the device. The dynamic screws convert the shaking to a rotational motion which produces a powerful counterweight effect. Because one device can control shaking in two directions with differing periods without increasing counterweight mass, it is lighter and uses less space than a conventional rooftop control device. This also makes it easier to install on the rooftops of narrow buildings.

The SMD structure consists of a steel or concrete counterweight* that is supported by a steel frame equipped with two layers of laminated rubber bearings. Oil dampers and dynamic screws are installed in the interior. The number of SMDs installed ranges from two to four devices, depending on the size of the building.

*Exterior dimensions: 7 m x 7 m; Weight: Around 400 tons

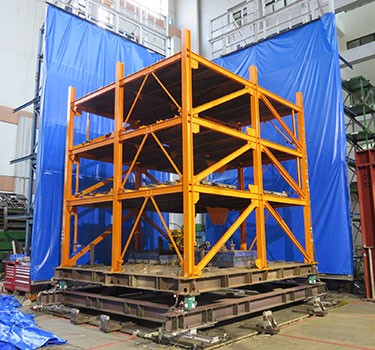

During development of the SMD, we performed a shaking experiment using a reduced scale model (equipped with a 30-ton counterweight) mounted on the large shaking table at the Institute of Technology. This verified the ability of the device to control shaking in two different directions.

Sloped Sliding Isolation Bearing (ANSHIN Slider)

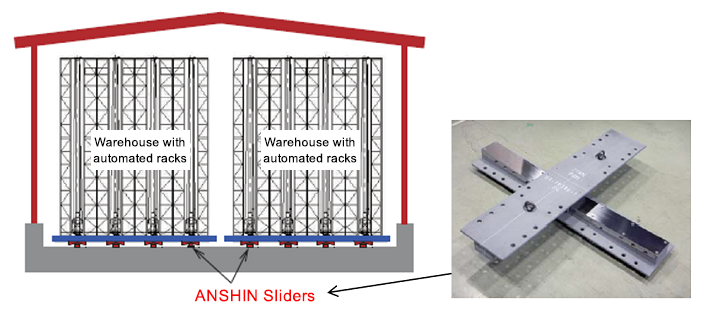

The ANSHIN Slider is a partial seismic isolation system that isolates important equipment from shaking and improves safety during an earthquake.

Installation of the ANSHIN Slider, a special seismic isolation device, between the floor of a structure and the equipment to be protected substantially reduces the acceleration generated in the equipment and prevents objects stored inside from falling over, even in a large earthquake with a seismic intensity greater than 6. Because this enables seismic isolation of the equipment to be protected without seismically isolating the entire building, it is a system that can also be installed at a reasonable cost when equipment is renovated. The seismic isolation device has a low height and offers the superior feature of controlling torsional vibration even when the load is unevenly distributed. It is used to seismically isolate automated racks in warehouses, servers, and other important equipment.

all of the necessary functions of a seismic isolation device (load-bearing,

seismic isolation, returns to original position after an earthquake, and attenuation).

Dynamic Rupture Simulations for the Megathrust Earthquake

Rupture Process of the 2011 Off the Pacific Coast of Tohoku Earthquake

The 2011 Off the Pacific Coast of Tohoku earthquake (Tohoku earthquake, Mw 9.0) occurred on the Japan Trench and caused a devastating tsunami. Studies of this earthquake have revealed complex features of its rupture process. Many studies of the 2011 Tohoku earthquake have shown this strikingly depth-dependent: the shallow parts of the fault, near the trench, produced large slip (~50 m) and long period seismic waves whereas the deep part of the rupture, near the coast, generated smaller slip and strong radiation of short period seismic waves. Indeed, other recent mega-thrust earthquakes showed similar depth-dependent rupture properties. Thus, understanding such depth-dependent features of the Tohoku earthquake rupture process is important for the estimation of seismic and tsunami hazard caused by possible mega-thrust earthquakes in other subduction zones, such as the Nankai Trough.

![Stress drop [MPa] distributions for our simulation](/en/company/about/sit/topics/topics01/images/img_index_06.jpg)

Large Scale Simulations of Rupture Propagation based on Dynamic Source Model

In order to understand such depth-dependent feature of the rupture process of the Tohoku Earthquake, we have investigated the large-scale computer simulations of rupture propagation based on dynamic source model. This dynamic source model utilizes the process about how the earthquake rupture goes based on the physics in contrast to the kinematic model that assumes the rupture process a priori. We used the 3D spectral element method on unstructured grids. This method is suitable to apply for the large-scale computer simulation. The simulation conditions are based on our previous papers (Tsuda et al., 2019, published on the Journal of Earthquake Engineering in Japan, and Tsuda et al., 2017, published on the Pure and Applied Geophysics). We show the stress drop distributions of the equivalent rectangular model on the following figure. They proposed the source model that could reproduce such depth-dependent feature of the rupture process of the Tohoku Earthquake.

The accompanying movie shows how the velocity field caused by fault rupture is propagated. The ruptures initiated on the off-Miyagi-Oki area propagated first toward to the east, and then they propagated along the Japanese Trench once they hit the surface. During this process, the seismic waves have been radiated and propagated through the medium.

Liquefaction Countermeasures

Three-dimensional Liquefaction Analysis (HiPER)

We developed the world's first three-dimensional liquefaction analysis program, HiPER(Bowl model). With this program, we have been able to rationally evaluate the liquefaction occurrence and the effect of liquefaction countermeasures in a manner that is close to the truth.

Low-cost Liquefaction Countermeasure for Small-scale Structures (Gravel Support)

Based on our proprietary evaluation technology that can predict deformation after liquefaction, we have developed a countermeasure method that can significantly reduce the inclination of structures caused by liquefaction by applying countermeasures only to areas close to the surface layer. This method can also be used for small-scale structures that have been difficult to deal with due to cost.