Preventing Water Pollution and Effective Use of Water Resources

Water Resource Conservation

Conservation Activities from Three Perspectives

At Shimizu, we work on conservation of water resources from three perspectives.

| Office activities | Reduce waste, use recycled water |

|---|---|

| Job sites | Use the technology we possess to improve efficiency, reuse water, and manage wastewater discharge |

| R&D | Research water reuse and treatment technology |

Conserving Water Resources at Offices

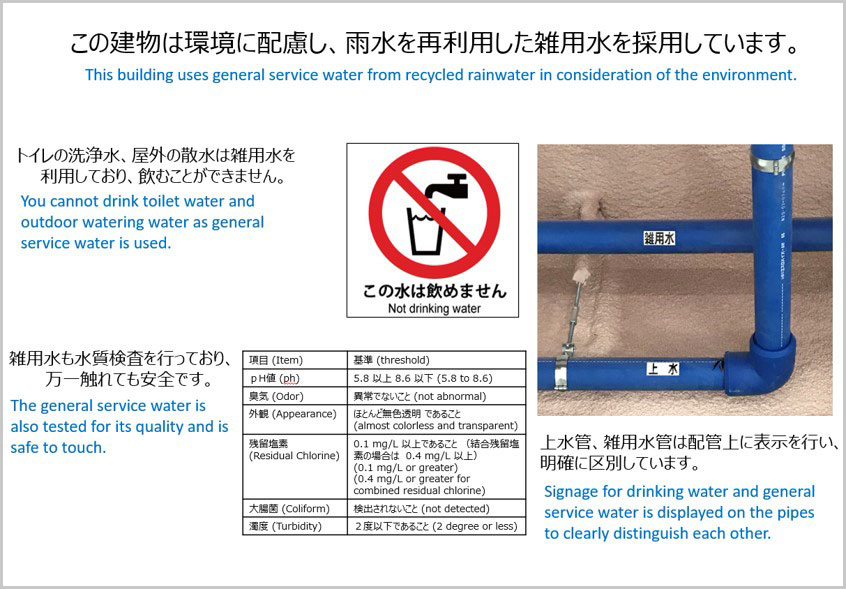

At the new Tohoku Branch building completed in March 2021, rainwater and well water are reused for toilet flushing and outdoor sprinklers as part of an initiative to conserve water resources. The building has obtained the highest level of WELL certification, the Platinum rank, and was designed with people's health in mind.

In addition, at Smart Innovation Ecosystem Novare, our innovation hub which began operations in September 2023, rainwater is used for toilet flushing, watering plants, and for the fire extinguishing system at the former Shibusawa Residence. We are also working to conserve water resources and reduce water consumption in our offices and company-owned facilities.

- Shimizu Complete Resilient Office Building to Both COVID-19 and Strong Earthquakes

- NOVARE (Only in Japanese)

Response on Conservation of Water Resources and Water Risks at Job Sites

The amount of water needed at a job site differs substantially, depending on the surrounding environment, type and size of building, construction method, and other factors. We repeatedly test and review the setting of quantitative goals for the amount of water withdrawn and wastewater discharged (usage volume and reduction in volume, etc.) in addition to the goals of reducing violations of environmental laws and regulations on water and mishaps.

In addition to working to reduce the unnecessary use of water at each job site, we take the information on local water risks (typhoon season, rainfall amount, volume of water withdrawn and discharged, restrictions on water quality, etc.) generated from committee meetings held at the time of design and at the time of a quote being generated, and confirm this information in a committee meeting before beginning construction. We then formulate a plan for appropriate water usage and execute it. In this water usage plan, we prioritize reducing the volume of water withdrawn and discharged, working to recycle and reuse water, and manage the quality of wastewater.

After beginning construction, a simple treatment water tank (notch tank) or a large turbid water treatment plant is installed, depending on the amount of water usage and project scale, and daily management and key point management is performed according to voluntary management standards that meet or exceed legally mandated standards. Various divisions in the company also perform checks through onsite patrols and audits, and strict management is performed until the project is delivered to the customer. This contributes to conservation of local water resources.

R&D related to water resource conservation

Per- and polyfluoroalkyl substances (PFAS) are used in various products, such as coatings and foam extinguishing agents. In recent years, however, their persistence and accumulation in the environment and living organisms have been recognized as a problem, and regulations are being tightened in Japan and abroad.

We have been engaged in R&D on purification technology for PFAS-contaminated water since 2021. A field test conducted in Okinawa Prefecture to purify PFAS-contaminated water confirmed the usefulness of the technology when contaminated water with a concentration of 634 nanograms (ng) per liter was purified to a concentration of less than 1 ng per liter.

In the future, we will roll out the technology to facilities where PFAS may have been sprayed and job sites where PFAS was manufactured or used, thereby contributing to water quality preservation.

- Shimizu's Engineering: Initiatives to Purify PFAS-contaminated Soil and Water (Only in Japanese)

- Shimizu Develops Technology to Purify PFAS-contaminated Water (Only in Japanese)

Effective Use of Water Resources

The job sites in each area are production locations in the construction industry. Water used in living and water used in construction is therefore withdrawn and discharged locally.

The methods for water withdrawal and discharge at construction sites and the countermeasures implemented in neighboring areas are provided in the form of a prepared chart of standards and operating manual used for the entire company.

The status of water resource withdrawal and discharge and the management plans for each business-related category are as shown in the table below: Based on management plans, we are working to effectively use water resources at all of our construction sites.

| Category | Status of Main Uses of Water Resources | Water Resource Management Plan | |

|---|---|---|---|

| Job Sites (in Japan) | Water withdrawal (municipal potable water, groundwater, surface river water*) |

|

As indicated below, management is performed according to the specific characteristics of the site and surrounding environment at each site.

|

| Water discharge (off-site water treatment) |

|

||

| Job Sites (Overseas) | Same as in Japan | Nearly the same as in Japan | |

| Offices in Japan & Overseas | Water use: Municipal potable water | Water used for daily activities |

Initiatives in Water Recycling

|

| Wastewater: off-site water treatment discharge | Wastewater from kitchen, washing/flushing, and rainwater | ||

| Supply Chain |

|

|

|

Shimizu obtains the proper permits for using groundwater, surface/river water, etc. in areas where municipal potable water cannot be used.

Shimizu engages in systematic efforts to improve water use efficiency and mitigate or prevent a negative impact. Below are several examples of specific initiatives.

| Water sprinkling to prevent dust | In cases where construction involves dismantling a building and requires sprinkling water to prevent dust, we reduced tap water usage by reusing the water that had collected in the underground spring pit during dismantling. |

|---|---|

| Reuse of Processing Water in Underground Pits | In cases where contaminated soil was excavated in underground pits and carried out, we initially used tap water to clean the pit after excavation and transport vehicle tires, but reduced water usage by treating water with water treatment equipment and recycling the treated water confirmed to meet the proper standards. |

| Use of Recycled Water in Tunnel Construction, etc. | We reuse water that wells up in the tunnel as construction water by using a turbid water treatment plant within the job site on projects involving tunnel construction and other types of construction as well, thereby recycling and reducing water use. |

Preventing Water Pollution

We work hard to prevent water pollution during construction by providing a Manual on Preventing Water Pollution at Job Sites, conduct e-learning courses, and holding meetings for the construction managers at each branch. We also implement various initiatives during Water Pollution Preventing Awareness Month in June of each year.

External Collaboration on Effective Use of Water Resources

Shimizu promotes joint research on water treatment, participates in water treatment projects, builds water treatment infrastructure, etc. in collaboration with external stakeholders.

Restoration and Utilization of Wetlands through Collaboration and Co-creation between Industry, Government, Academia and the Private Sector

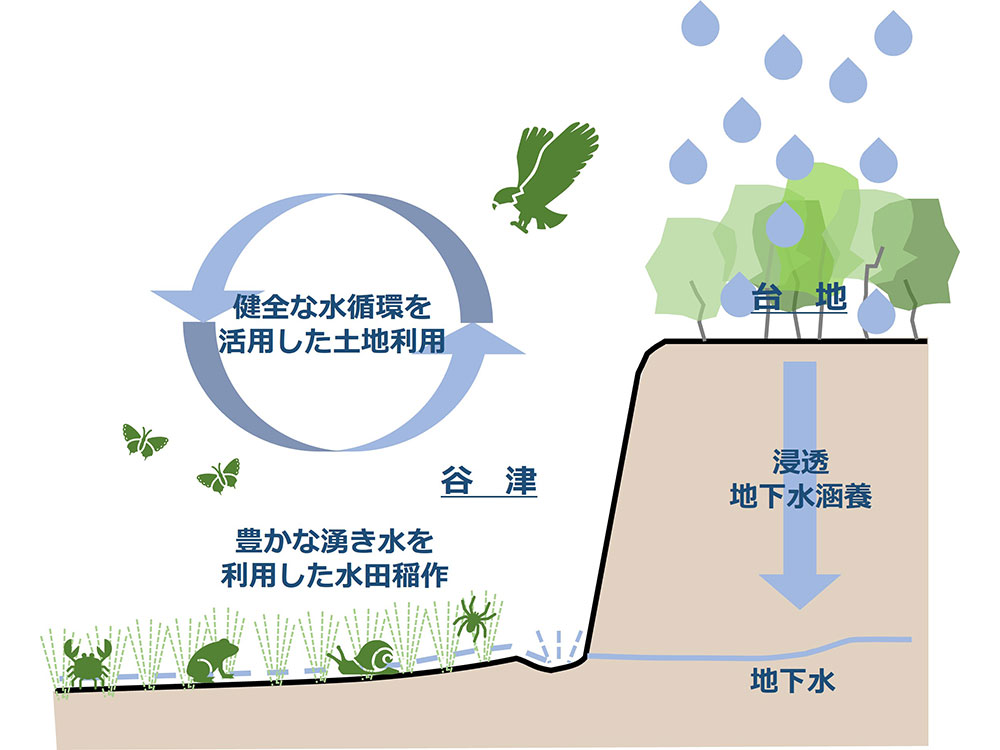

Since 2021, we have been promoting a green infrastructure project called Yatsubori no Shimizu Yatsu to regenerate the wetlands of small valleys* in Tomisato, Chiba Prefecture as multi-functional wetlands through collaboration between industry, government, academia, and the private sector. Enhancing water purification and rainwater storage functions, restoring wetlands may help maintain a healthy water cycle in the region and reduce the risk of flooding.

In fact, we were able to create a natural symbiosis that attracted many aquatic plants and animals that prefer the valley environment.We will continue to create wetland green infrastructure where people and nature can coexist and return nature's bounty to the region so that valley functions can be preserved for the future.

Yastu…Small valleys formed by erosion of plateaus and hills

- Yatsubori no Shimizu Yatsu (Only in Japanese)

- Yatsubori no Shimizu Yatsu received the Minister of Land, Infrastructure, Transport and Tourism Award in the 4th Green Infrastructure Awards. (Only in Japanese)

Building Water Treatment Infrastructure

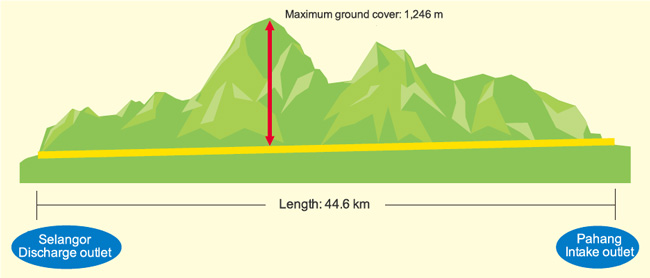

- Pahang-Selangor Raw Water Transfer Tunnel (Malaysia)

- At 44.6 km long, this is Southeast Asia’s longest water conduit tunnel. It was built to supply 1.89 million m3 of water per day to the Kuala Lumpur greater metropolitan area and Selangor State from neighboring Pahang State to provide a stable supply of water for daily life and commercial use.

This project was part of Greater KL, a national project to transform the greater metropolitan area into a global international city and provide an engine for economic growth. It involved over 100 local staff members, 1,000 workers from 12 countries, and a construction period of 1,800 days. It was completed in May 2014.

- Sewer Systems and Treatment Facilities in Malaysia and Vietnam

- Shimizu built four sewage treatment facilities, one slurry treatment facility, roughly 5.4 km of a main sewage line, and 17.3 km of a sewage pipeline network for the area surrounding Kuala Lumpur. We also built a sewage treatment facility in Ho Chi Minh. Both projects were completed in 2009.

Business Activities in Water-stressed Areas Overseas

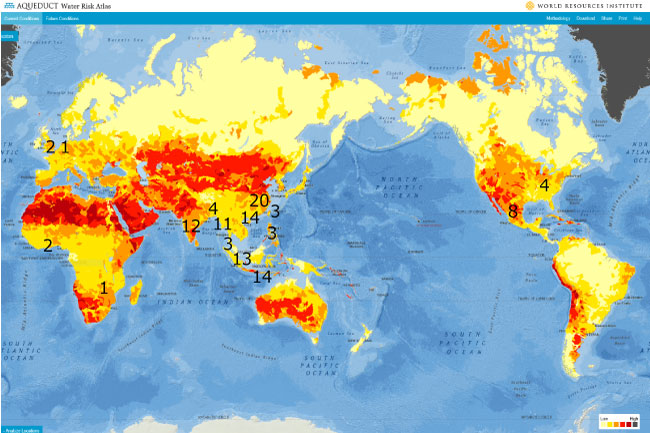

We manage the water risks of business activities (building construction and civil engineering) in water-stressed regions, utilizing the World Resources Institute’s (WRI’s) Water Risk Atlas.

Figures indicate the total number of construction and civil engineering projects in each country.

Shimizu’s business activities in regions identified to be potentially exposed to water stress are listed in the table below.

Of the overseas job sites scored according to five levels of water risk, none were in areas of “extremely high risk.” There were total of 13 job sites in areas of “high” risk, located in China, India, and Mexico, accounting for 12% of all overseas job sites (less than 1% of all job sites, when including job sites in Japan).

In the future, we will continue to target strict risk management in advance and respond to restrictions in water management as we carry out business activities in areas of high water risk.

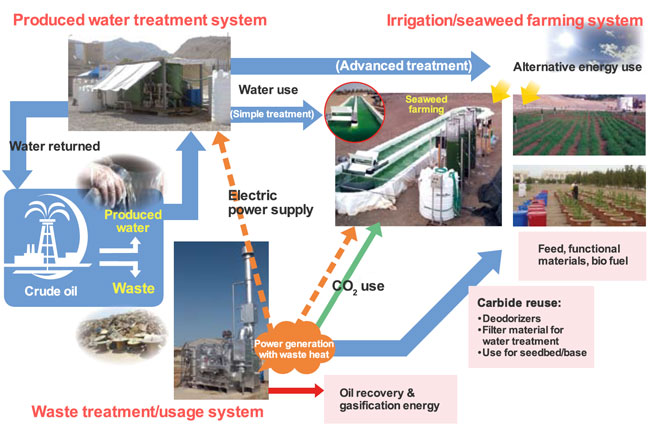

Produced Water Project (1996-)

We are developing simple, versatile and highly efficient produced water treatment technology to turn produced water containing oil into a water resource. We are doing that in cooperation with the Japan Cooperation Center for Petroleum and Sustainable Energy, Sultan Qaboos University and the Oman Ministry of Oil & Gas.

Produced water containing oil is groundwater which is pumped up in a volume three to five times or more of crude oil at the same time as mining for crude oil. Oman is home to areas which generate produced water at 200,000 m3 per day, more than half of the amount of water supplied to the capital of Muscat, from one oil field. This water contains oil and harmful heavy metals. Therefore, it is difficult to treat and most is returned underground as waste. However, we are developing produced water treatment technology which utilizes this produced water as a new water resource. We have currently achieved a level for treated produced water which satisfies irrigation water standards.