Building Lives and Protecting Communities

Tackling the highly difficult task of constructing the Steel Frame

for a Complex Stadium Main Stand

Construction work on the New Miyazaki Prefectural Athletic Stadium (1 construction section)

The 81st Japan Games (formerly National Sports Festival of Japan) and the 26th National Sports Festival for People with a Disability will be held in Miyazaki Prefecture in 2027. Construction of sports facilities is progressing in various parts of the prefecture.

A joint venture formed by Shimizu and local companies is taking on the construction of the main stand, north and south side stands, and field of the New Miyazaki Prefectural Athletic Stadium, which will be the main stadium for the festivals.

Class 1 certified track and field stadium

Construction of a new track and field stadium is progressing ahead of the 81st Japan Games and the 26th National Sports Festival for People with a Disability to be held in Miyakonojo City, the second most populated city in Miyazaki Prefecture, in 2027.

It will hold around 15,000 spectators. A Class 1 certified track and field stadium, it can be used for national and international competitions organized by the Japan Association of Athletics Federations, such as national championships. A joint venture formed by Shimizu and local companies is in charge of constructing the main stand, north and south side stands, and field.

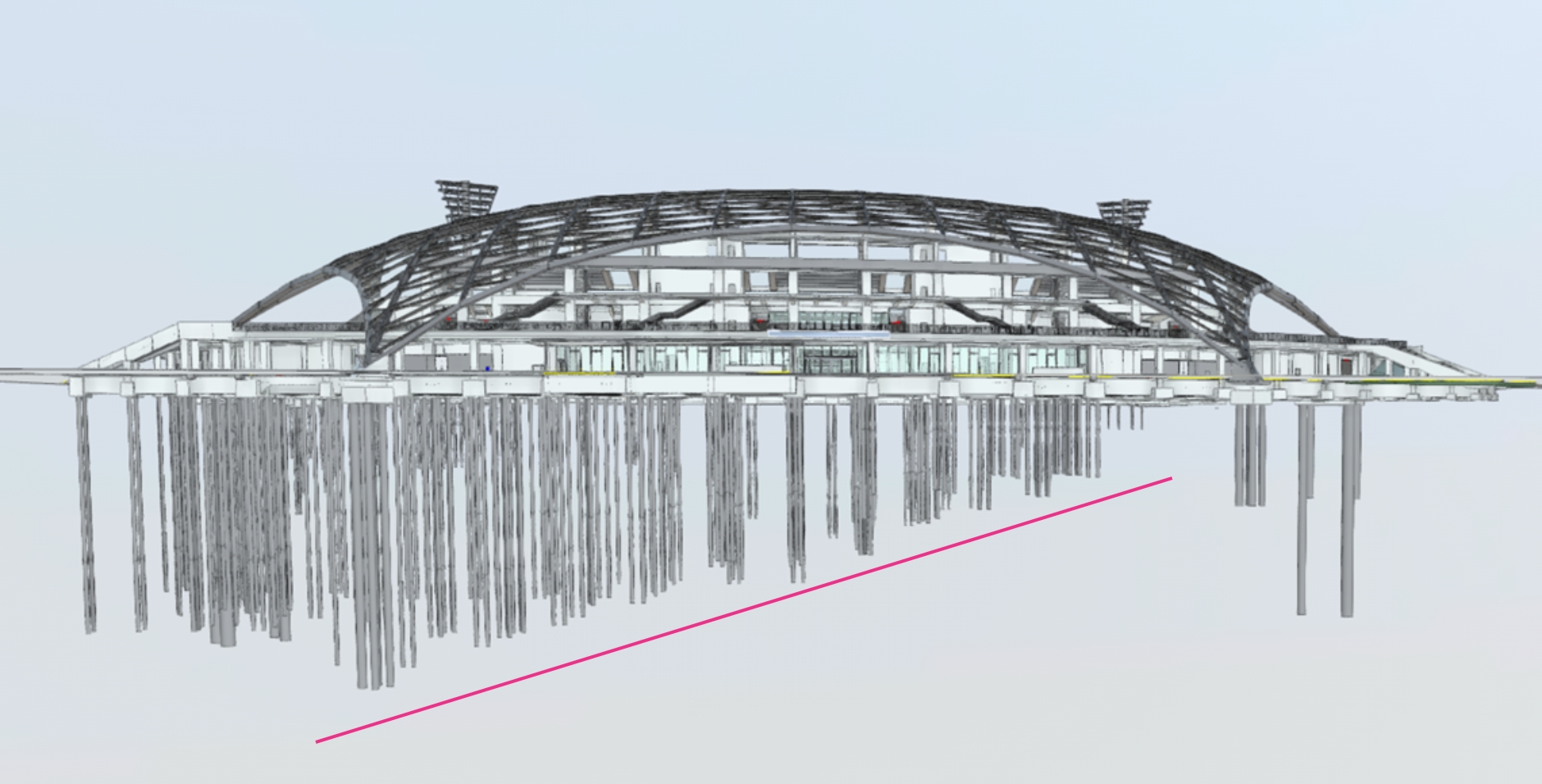

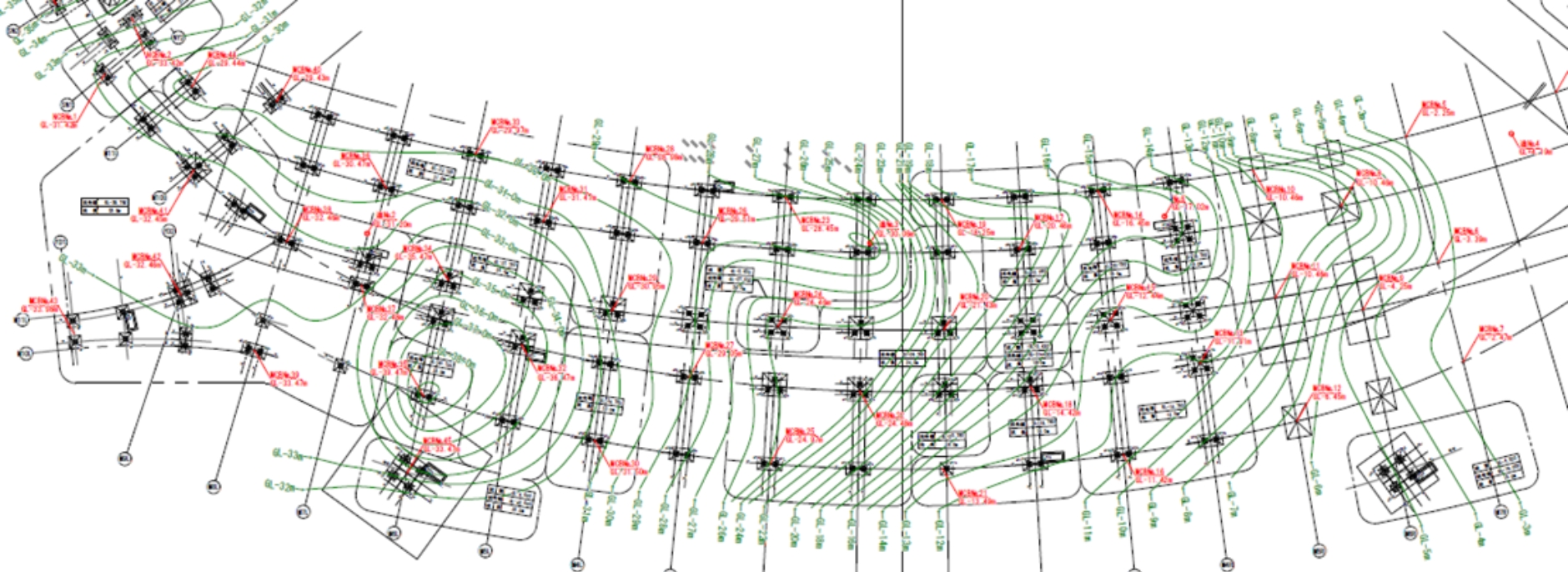

Sloped pile support layer

The main stand’s piles consist of both cast-in-place concrete piles and pre-cast concrete piles. The construction site had complex geological conditions, with the support layer sloping deeper from south to north. To ensure the embedded length of the prefabricated piles reach the support layer, we conducted a detailed investigation of the ground conditions at the site through boring surveys at 45 locations. We created a contour map of the support layer to determine the pile length.

There are a total of 257 prefabricated piles: 177 with a diameter of 600 mm and a length of 14 to 36 m, and 80 with a diameter of 500 mm and a length of 13 to 36 m. It took about three months to drive the piles using three pile drivers, and we confirmed that all the piles reached the support layer.

Performing a detailed construction analysis to complete the complex steel frame construction

The steel frame of the 1,400-ton roof on the main stand was prefabricated on the ground into units of main beams, secondary beams, and purlins, then welded together and painted. By minimizing the amount of work done at height, we ensured safety and quality.

The construction of the steel frame of the main roof is carried out by temporarily supporting the weight of the roof with temporary supports called bents, and then jacked down to make the roof self-supporting. With the support of the Engineering Headquarters, we conducted more than 40 detailed construction analyses and drew up the optimal steel frame construction plan from among them. After jacking the roof down, our verification showed that the precision was close to the pre-analysis values, allowing us to complete the subsequent construction phases without any issues.

Kazuki Ikeda, the site representative and construction manager, says of his hopes for the project, “Our slogan for the construction site is ‘One Team: Bringing Master Craftsmanship to the Sunny Land of Miyazaki, Japan.’ I want to work together with our customers, designers, and subcontractors to deliver a facility that exceeds the expectations of the citizens of the prefecture.” Construction is scheduled for completion in December 2024. We will continue to put safety first.

Overview of Construction

- Construction site

- 2381-4 Hananoki, Yamanokuchi-cho, Miyakonojo City, Miyazaki Prefecture

- Client

- Miyazaki Prefecture

- CM

- Plus PM

- Design and supervision

- Sato & Masuda Architectural Design and Construction Supervision Joint Venture

- Construction period

- December 2021 - December 2024

- Structure and scale

Reinforced Concrete, Steel 4F

Building area 14,741 m2

Total floor area 22,809 m2

The information posted here is the current information on April 22, 2024.

Please be aware that this information may have changed by the time you view it.