Provides a cleanroom environment to accommodate various needs

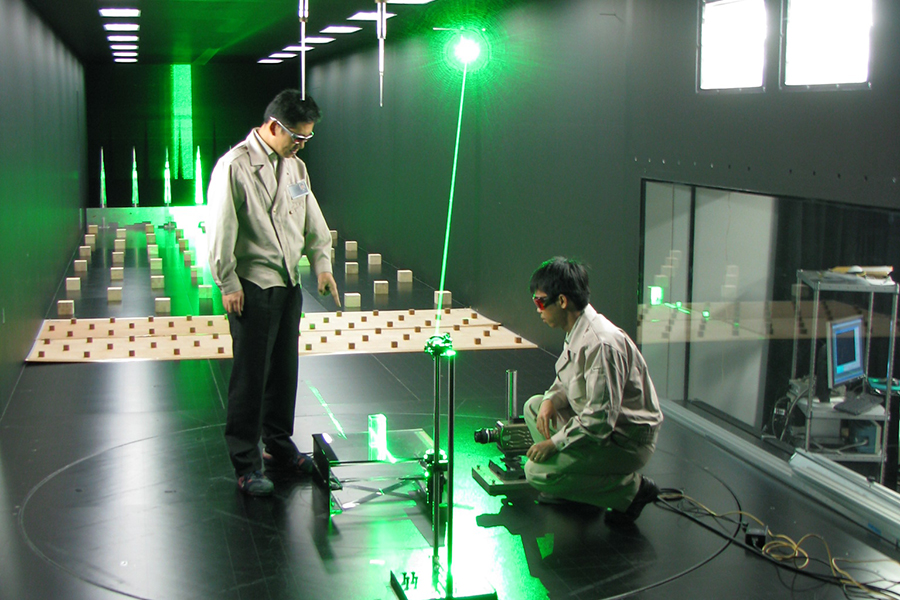

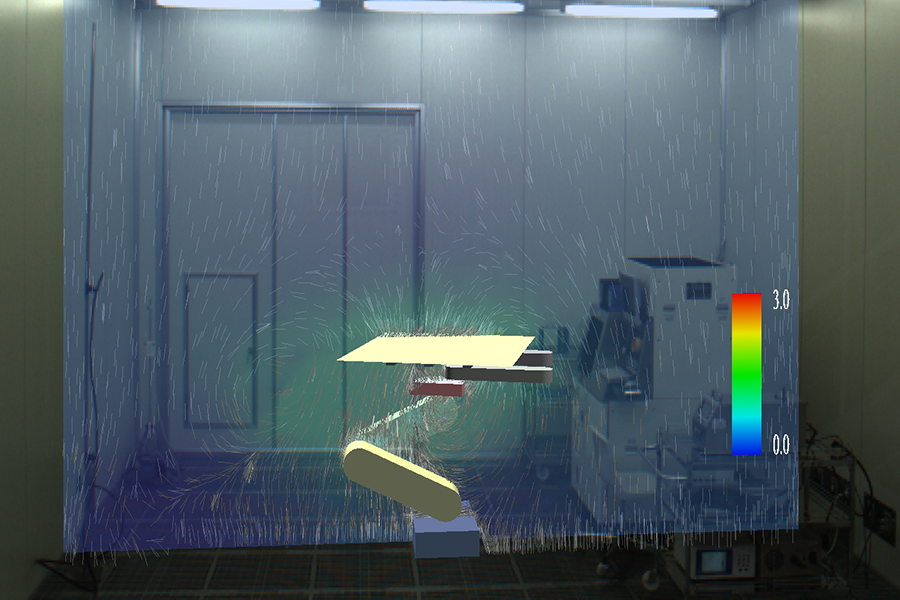

In our Cleanroom Laboratory, we perform many kinds of experiments and evaluations of cleanroom environments, including experiments to verify airflow, degree of cleanliness, temperature, and other factors, analysis of chemical substances in the air, measurement of chemical substances emanating from construction materials, cell culturing related to regenerative medicine, and other work.

We have installed multi-step seismic isolation systems and high-performance dampers in our Cleanroom Laboratory as earthquake mitigation technology that we have developed to match the specific characteristics of the lab.

Types of Testing

- Optimization of cell culture environment

- Robotic-arm system to improve the efficiency of cell culture process

- Development and testing of air cleaning systems

- Recovery performance testing

- Testing to evaluate the effects of the particle generation

- Verification testing on temperature distribution

- Analysis of chemical components in air

- Decontamination system testing

- Analysis of chemical substance emissions from construction materials

- Testing to predict chemical filter lifespan

Facility Features

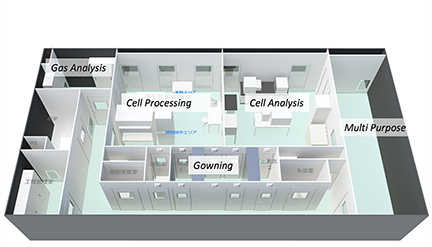

Shimizu Cell Laboratory(S-Cell Lab) for Regenerative Medicine

S-Cell Lab enables real-time monitoring of the cell culture environment and integrated experimental verification of the cell culture process to meet the need for construction of cell culture facilities.

Super-Nano Cleanroom (SNCR)

This cleanroom achieves the world's highest cleanliness levels and moisture control. Cleanliness levels can be adjusted to enable verification of the clean environment required by each customer.

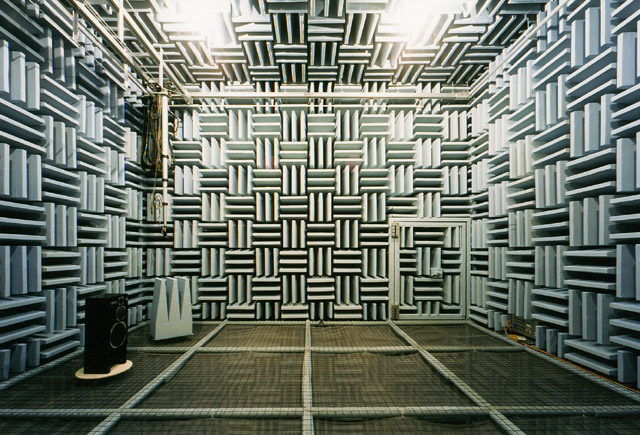

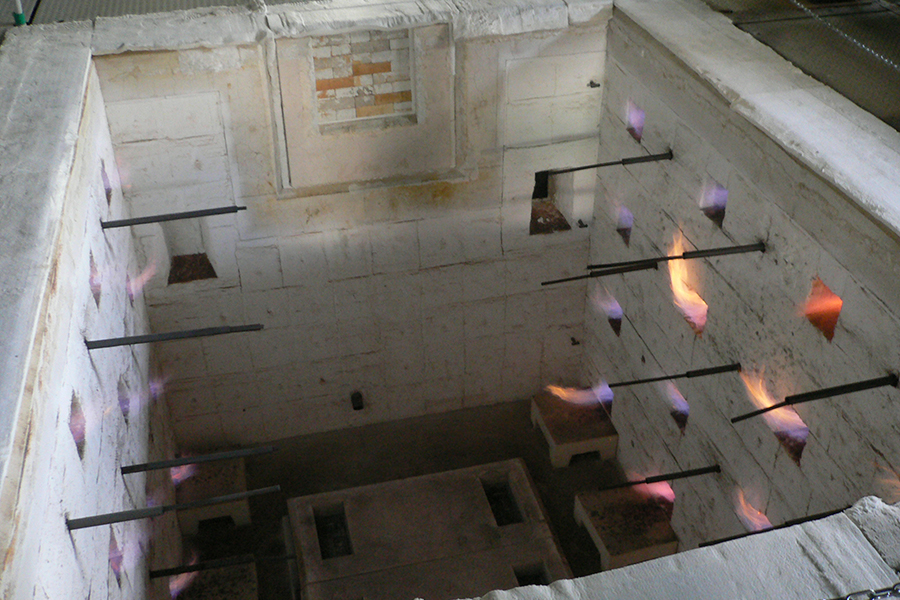

Mock-up Cleanroom (MCR)

The largest cleanroom owned by any construction company, this space has a ceiling height of 14 meters. It can be used to perform experiments with actual large-scale manufacturing equipment or life-size models.

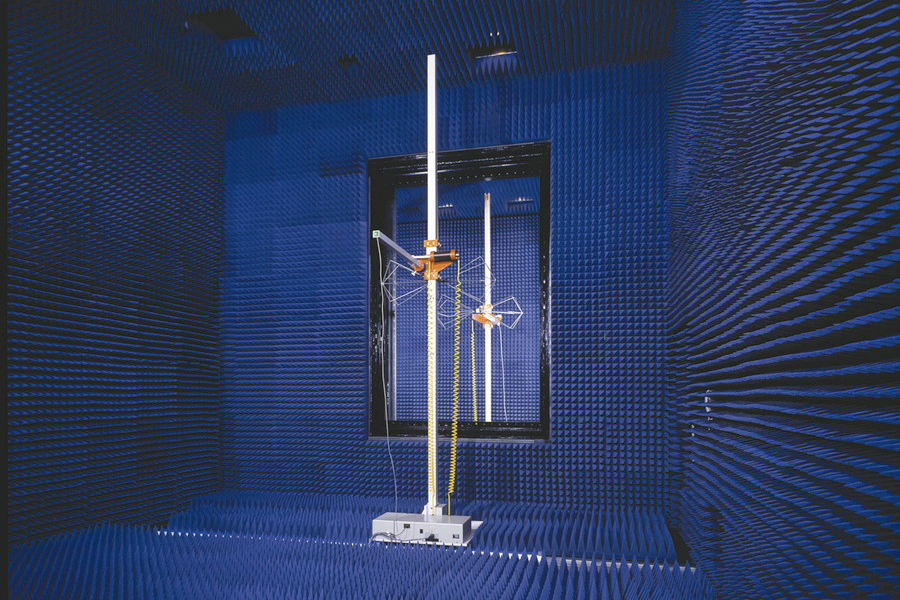

Bio Cleanroom (BCR)

This cleanroom can be used for verification experiments involving biotechnical cleanroom technologies required by pharmaceutical factories and medical institutions.

Chemical Testing Room

Various types of chemical experiments can be performed in a clean environment.

Instrumental Analysis Room

This room is equipped with a gas chromatograph, an ion chromatograph, ICP-MS, and other equipment that can rapidly verify cleanroom performance and investigate the cause of a malfunction.

Outgassing Testing Room

This room is equipped with chambers of various dimensions and is used to evaluate the emission of chemical substances from construction materials, furniture, and various other components and materials. It also supports countermeasures to chemical contamination and to sick buildings.

Examples of Tests and Achievements

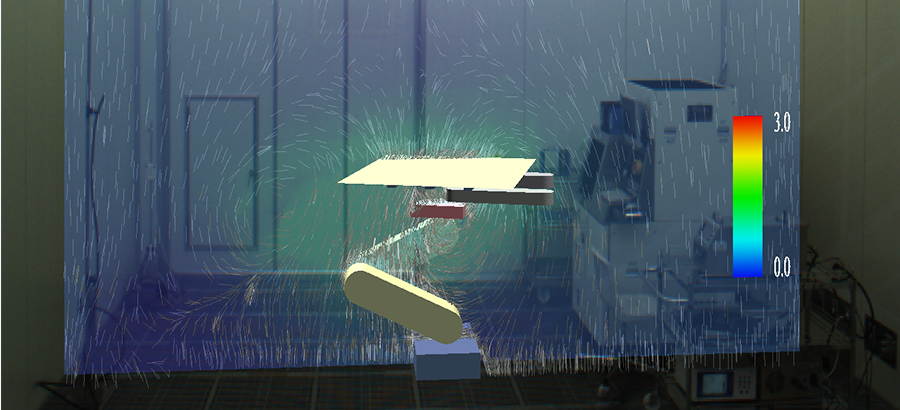

- Development of task and ambient air cleaning system

- Development of PAC-style task and ambient air cleaning system

- Development of displacement air cleaning system

- Development of cleanroom BEMS

- Chemical component monitoring system

- Ammonia monitor

- Development on assessing the particulate containment performance in facility for high potent pharmaceutical compounds

- Development of a super-nano cleanroom

- Development of a PAC system that processes external air

- S-PiCS (SHIMIZU Pharma-isolator Clean System)

- Development of materials with low outgassing (coatings, sealants, cables, concrete, etc.)