Temples and Shrines Construction Restoration of Aso Shrine Completed with Reconstruction of Romon Gate Preservation and Repair Work on Romon Gate of Aso Shrine, a Nationally Designated Important Cultural Treasure

Restoration of Aso Shrine completed with reconstruction of Romon Gate

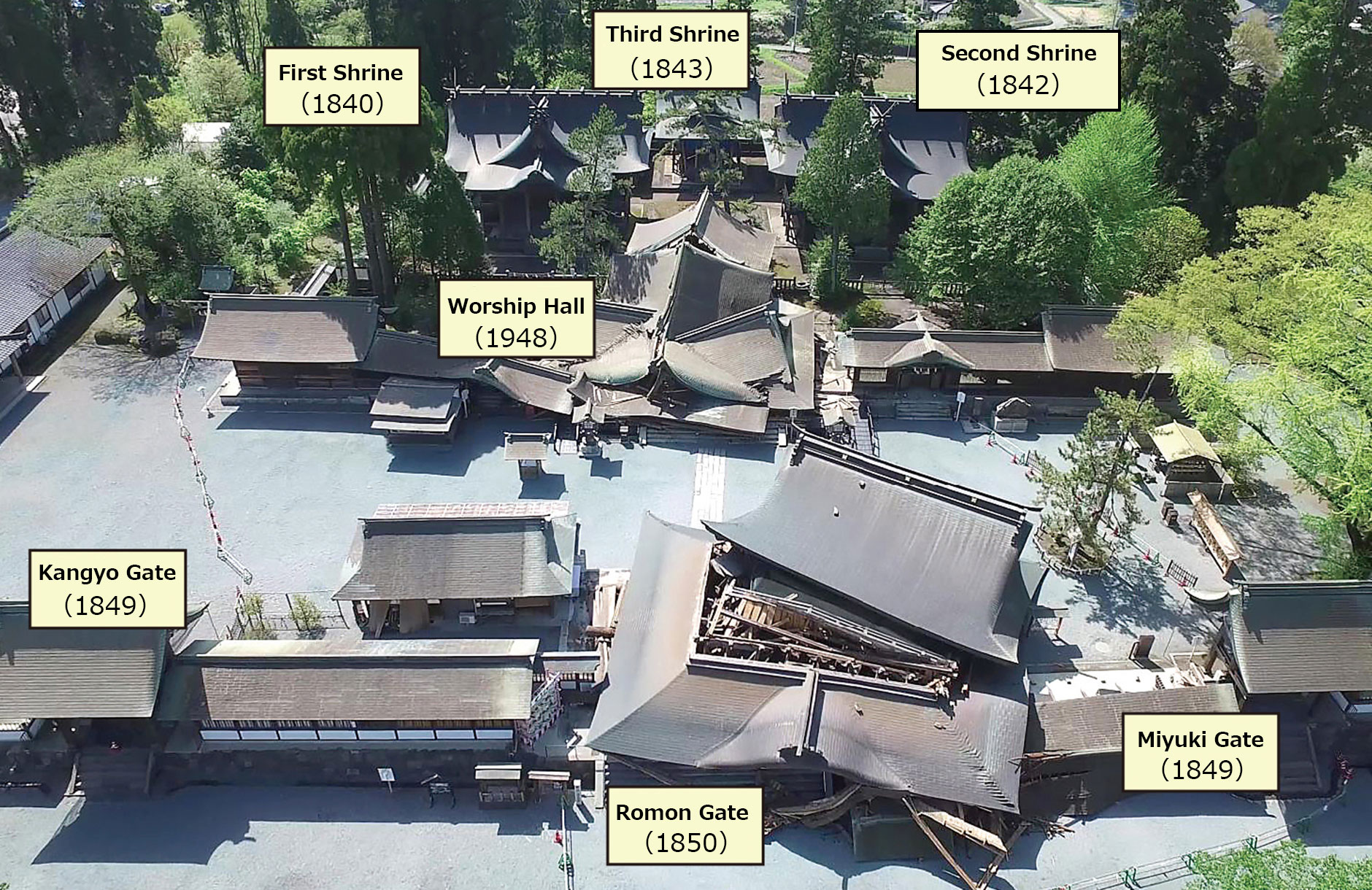

Aso Shrine, a symbol of the Aso region, stands again in all its historic glory now that the reconstruction of the Romon Gate, the last remaining part of the restoration work, is complete. Tragically, the April 2016 Kumamoto Earthquakes razed the Romon Gate, considered one of Japan’s three great romon gates, to the ground. They also damaged the Third Shrine and partially damaged the First Shrine, Second Shrine , Miyuki Gate, and Kangyo Gate.

Meticulous handling of the smallest fragments

Located in the Aso region of Kumamoto Prefecture, Aso Shrine is an ancient shrine with a history going back more than 2,000 years and around 500 branch shrines throughout Japan. Built in 1850 at the end of the Edo period, Romon is a dignified two-story structure featuring a gabled roof and bow-shaped eaves.

In April 2016, six important cultural treasures suffered extensive damage in the Kumamoto Earthquakes. We were contracted to undertake the monumental task of restoring these properties following the disaster. Five of the six buildings underwent restoration during the first construction phase from October 2016 to March 2019: the damaged Third Shrine, the partially damaged First Shrine, Second Shrine, the Miyuki Gate, and the Kangyo Gate. During this period, we dismantled, studied, cataloged, and preserved the Romon Gate under the supervision of the Japanese Association for Conservation of Architectural Monuments .

The first step in dismantling the structure was to construct a temporary roof cover 9.8 meters high, 22.5 meters wide, and 25.3 meters deep to cover the collapsed gate. The dismantling work then began with the upper roof section. Without a complete picture of how the pieces overlapped, the work was performed under the threat of secondary disasters due to load imbalances. Due in part to the Romon Gate being made of high-quality materials that are not available today, we carefully removed the individual pieces after ensuring it was safe so as not to harm its value as an important cultural treasure. All the dismantling was carried out meticulously, giving attention to even the smallest fragments.

72% of materials reused

About 11,000 pieces of material were salvaged from the Romon Gate, and wooden tags with the collection location and serial number were attached to each one before they were transferred to a newly constructed shed on the temple grounds for preservation. Every piece was examined for damage. As the building is an important cultural treasure, restoration efforts prioritized the use of original materials wherever feasible. Accordingly, repairs other than heavy structural materials began with classifying the materials into those that could be reused, those that required partial repairs, and those that needed to be replaced.

In addition to wood-rotting fungi entering the wood and rotting it due to prolonged dampness and materials being hollowed out by termites, many pieces were damaged by breaking off or being wedged in between other pieces during the collapse. As such, we determined the best repair method for the condition of the piece’s damage, such as using adhesive to attach parts that were about to come off, removing the damaged part but only taking as little as possible, and filling it with another piece of wood, or reinforcing the connection between the new wood and the existing wood. Then, we carried out the repairs and fabrication of replacement parts. Thanks to painstaking efforts, we were ultimately able to reuse 72% of the materials.

Balancing tradition with technology

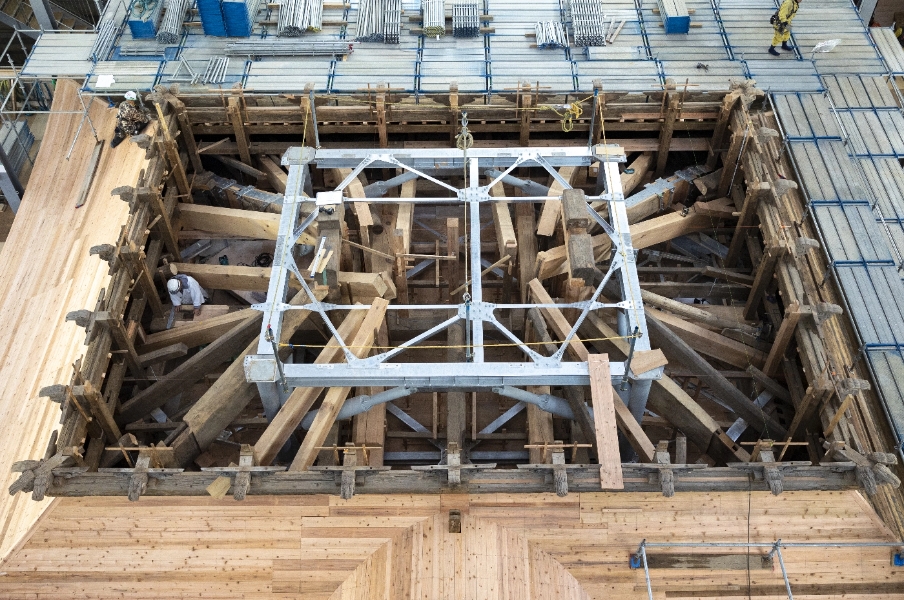

Reconstruction of the Romon Gate took place in the second construction phase from April 2019 to December 2023. In the construction work on the foundation, the ground was excavated in a grid pattern and filled with H-beams. Four steel frames for seismic reinforcement were erected on top of the H-beams, and a pressure-resistant concrete foundation for the gate was poured. The strategy was to improve earthquake resistance by connecting this steel frame to the wood. A new temporary roof cover 24.1 meters high, 22.5 meters wide, and 25.3 meters deep covering the construction yard was then erected, and heavy structural pieces such as large columns and hip rafters were restored inside. Repair and reinforcement involved augmenting old and new lumber with aramid rods and wrapping them with steel plates.

After the pillar erection ceremony in February 2021, the construction of the main body of the gate began. Methodically determining the placement of the materials, we repeated a process of seamlessly installing seismic-resistant steel frames within the original structural framework and connecting them.

A rewarding job

In September 2022, after a successful topping out ceremony (framework completion ceremony), we started carefully installing the copper shingles on the roof one by one. By March 2023, the copper shingling of the roof was completed. After dismantling the temporary roof cover in July, we laid the concrete around the gate and restored the notice board. The restoration of Aso Shrine was completed with the reconstruction of Romon Gate, and a completion ceremony was held on December 7. This was the day that Terasaka’s wish came true that the Romon Gate would continue to watch over the community for many years to come.

Terasaka says, “We heard from many locals that they felt the shrine had taken on the damage in their stead when the Romon Gate collapsed. During the construction period, I remember going to the shrine for morning worship after the morning meeting and receiving purification rites before starting work. We faced a number of difficulties along the way, but we overcame them and completed the construction. I am grateful to have been involved in this very rewarding job.”

The shiny copper-shingled roof has already begun to change color, giving the gate an aged appearance that harmonizes with the surrounding scenery. On the day of the completion ceremony, visitors seemed to have a gleam in their eyes when asked to share their thoughts with the TV news crew covering the Romon Gate restoration. We remain committed to passing down our expertise and continuing our societal contributions through endeavors that future generations can take pride in.

Overview of Construction

- Address

- 3083-1 Miyaji, Ichinomiya-machi, Aso City, Kumamoto

- Client

- Aso Shrine

- Design and supervision

- Japanese Association for Conservation of Architectural Monuments

- Construction period

- April 2019 - December 2023

- Structure and scale

Wooden 2F

Building area 81m2

Total floor area 130m2

The information posted here is the current information on March 11, 2024.

Please be aware that this information may have changed by the time you view it.