To achieve a zero-carbon society, we aim not only for zero CO2 emissions from Shimizu’s workplaces and offices but also for zero CO2 emissions in the operations of buildings we design and construct. We are also promoting decarbonization efforts on many fronts by constructing renewable energy facilities, promoting renewable energy businesses, and developing decarbonization technologies.

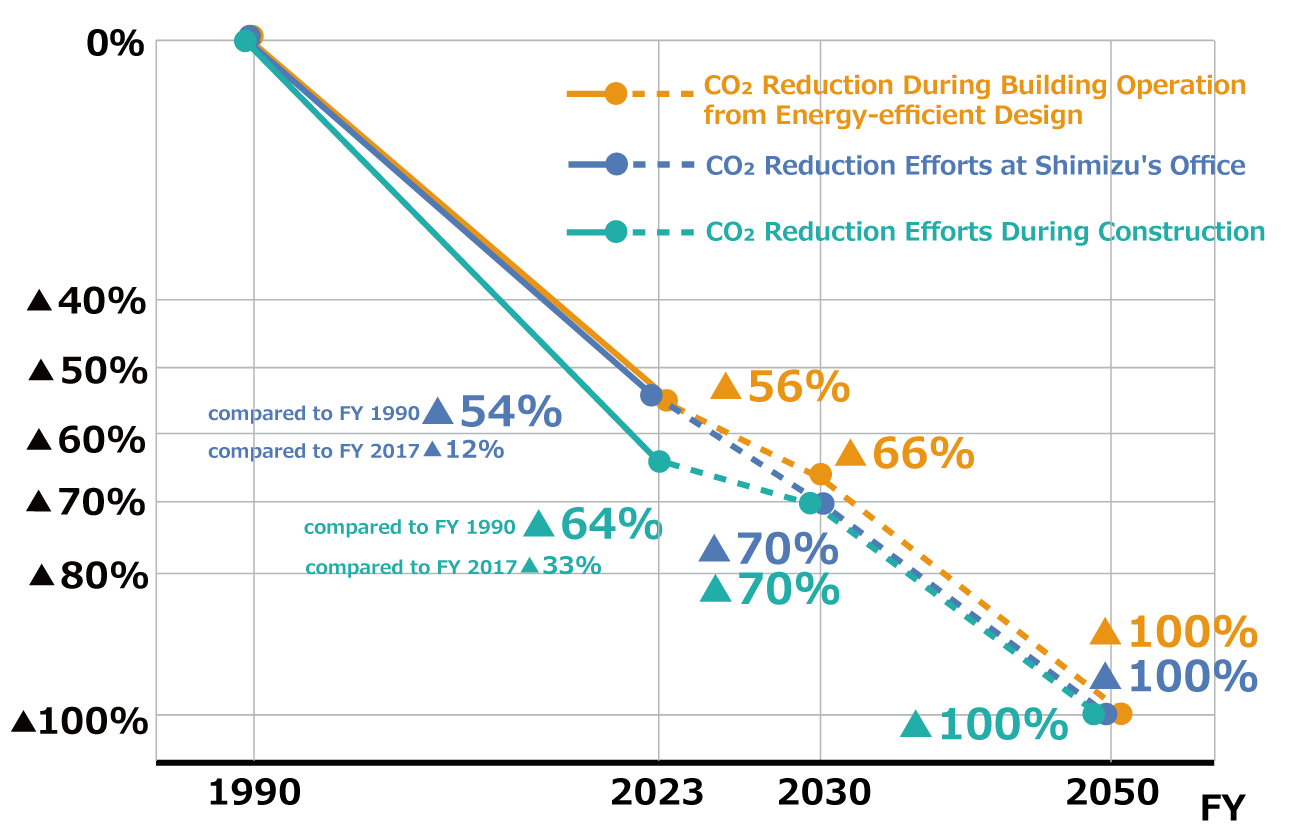

Ecological Mission 2030-2050

We view climate change as one of our key management issues and are promoting efforts to mitigate and adapt to it.

We have established Measures to Combat Climate Change (Ecological Mission 2030-2050) and have set targets for each category of construction, Shimizu offices, and energy-saving construction. The entire company is working together to achieve these targets. In addition, based on the Group environmental vision, SHIMZ Beyond Zero 2050, we have set forth the target of achieving zero CO2 emissions by FY2050.

CO2 Reduction Efforts During Construction

- FY 2022 Results

- 178,000 tons of CO2 emissions

Reduction of 67%

compared to FY 1990 - FY 2023 Goal

- Reduction of 61%

compared to FY 1990

CO2 Reduction Efforts at Shimizu's Office

- FY 2022 Results

- 8,100 tons of CO2 emissions

Reduction of 53%

compared to FY 1990 - FY 2023 Goal

- Reduction of 54%

compared to FY 1990

CO2 Reduction During Building Operation from Energy-efficient Design

- FY 2022 Results

- 75,100 tons of CO2 emissions

Reduction of 53%

compared to FY 1990 - FY 2023 Goal

- Reduction of 55%

compared to FY 1990

Due to the nature of the construction industry, our achievements vary depending on number of contracts we get rewarded every year. The target values are lowered gradually toward the FY2030 reduction target.

Initiatives for CO2 emission reduction of construction

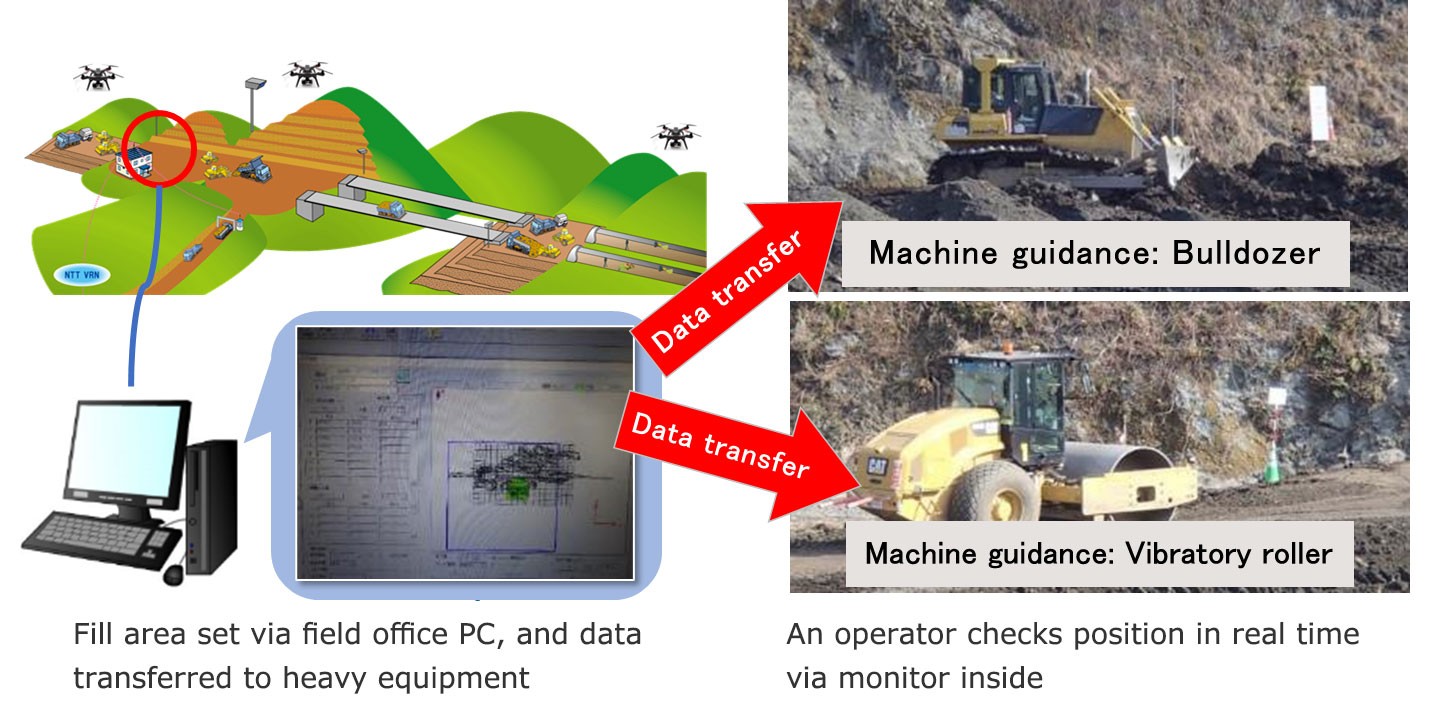

Energy productivity improvement through ICT-based construction

We are deploying ICT-based earthwork by displaying three-dimensional data, including measurement and design data, on a monitor inside heavy equipment, which enables heavy equipment operators to manage the construction conditions in real time. Optimal operation of construction machines improves construction efficiency, which allows us to reduce CO2 emissions (improve energy productivity).

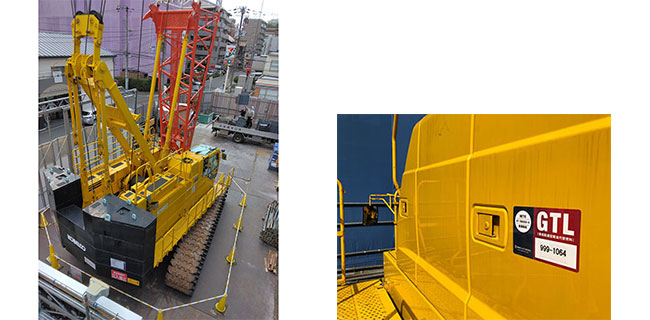

Alternatives to diesel fuel

Most of the CO2 emitted at construction sites is due to the use of diesel fuel for heavy equipment. We are actively using environmentally friendly alternatives to diesel fuel, such as next-generation biodiesel fuel derived from microorganisms and Gas-to-Liquids fuel derived from natural gas, in our crawler cranes and others used at construction sites.

Aggregate and sediment transport using belt conveyors

By using belt conveyors to transport dirt, sand, and crushed stones generated during large-scale site preparation, tunnel construction, dam construction, and other projects, we can significantly reduce CO2 emissions generated by dump trucks. In addition to reducing CO2 emissions, the conveyors helps to reduce traffic congestion caused by trucks in urban areas.

Initiatives for CO2 emission reduction at Shimizu offices

Achieving carbon-free operations at head office building

The head office building uses electricity generated by solar panels installed on the exterior walls to power its daytime lighting and also utilizes Aqua Premium green electricity derived from hydroelectric power generation (provided by TEPCO Energy Partners Co., Ltd.), thereby ensuring that all the electricity is carbon free.

We are also working to reduce CO2 emissions at our branch offices all over the country by gradually converting to net zero energy buildings (ZEB) and introducing green electricity.

Initiatives for CO2 emission reduction during building operation from energy - efficient design

Spreading of ZEB

Currently, the popularization of ZEB is required to achieve the government’s target of carbon neutrality by 2050 as these buildings use significantly less energy.

We have been working to spread ZEB ahead of others in the industry. The main building at our Institute of Technology, completed in 2003, achieved a 43% reduction of greenhouse gas emissions compared to FY1990. In 2016, our design-build wooden architecture became the first ZEB in Japan to acquire third-party certification.

Today, we are promoting ZEB not only to new buildings but also to existing buildings but also at existing buildings as we work towards the realization of a zero-carbon society.

- Business topics: Realizing ZEB through sustainable renovation

- Business topics: Changing the future of Japan with ZEB

Hydro Q-BiC, a Hydogen system

As part of our efforts to realize a zero-carbon society, we have developed and commercialized the Hydro Q-BiC in collaboration with the National Institute of Advanced Industrial Science and Technology (AIST).

This system produces and stores hydrogen with the surplus electricity from solar power generation during times of low electricity demand and generates electricity with a reaction between hydrogen and oxygen when the building’s electricity demand increases, thereby making it possible to conserve energy without wasting any electricity.

- Technical solutions: Hydro Q-BiC Hydrogen Energy Utilization System for Buildings (only in Japanese.)

- News release: Verifying the CO2 reduction effect of the Hydro Q-BiC (only in Japanese.)

Promoting CO2 absorption with impregnant applied to concrete surface

We jointly developed Direct Air Capture (DAC) Coating, a technology that promotes CO2 absorption from the air using existing concrete structures, with Hokkaido University. With the application of an impregnant to its surface, the concrete structure absorbs and fixes at least 1.5 times more CO2 from the air. Moreover, because it is also anti-corrosive, it reduces rebar corrosion caused by concrete carbonation, helping to extend the life of reinforced concrete, thereby contributing to the realization of a carbon-free society.

We will contribute to the realization of a carbon-free society throughout the building life cycle, from material procurement to construction and building operation.

Initiatives for realizing a zero-carbon society in non-construction businesses

Offshore wind firm

Among sources of renewable energy, offshore wind firm has tremendous potential owing to the scale and stability of its power generating capacity. We have one of the world’s largest self-propelled Self-Elevating Platform (SEP) vessels capable of being used in the construction of large-scale 14-15 MW wind turbines so that we can contribute to the expansion of offshore wind firm.

Our aim is to obtain the top offshore wind firm facility construction market share in the industry by having SEP vessels capable of use in reliable and efficient construction of large wind turbines.

Reducing CO2 at the properties we develop

In our real estate development and management, we are improving the energy-saving performance of rental properties, introducing electricity generated from renewable energy, and working together with tenants to reduce energy use. We have set forth four independent targets to contribute to a carbon-free society throughout the supply chain, namely, introducing electricity generated from renewable energy, reducing CO2 emissions, acquiring external environmental certification, and publishing energy consumption and other such data. We are also rolling out rental properties running on electricity generated from renewable energy featuring advanced energy-saving performance as part of our Green Property+® series.

Renewable energy business

We are also actively working on the business of generating renewable energy, including wind, solar, biomass, hydraulic, and geothermal power and the retail electricity business.

Since 2020, we have been operating a community-based biomass power generation facility in Tomi City, Nagano.

- Special site: Business of generating renewable energy promoted by Shimizu (only in Japanese.)

- Business topics: Contributing to local forestry and prevention of global warming with community-based 2 MW class biomass power generation

Wholly owned subsidiary Smart Eco Energy, which is engaged in the retail electricity business, also provides decarbonization solutions such as sales of renewable energy certificates (RECs) and is promoting the shift to renewable energy in the electricity used for construction through the use of RECs at our construction sites.