SUSMICS Series

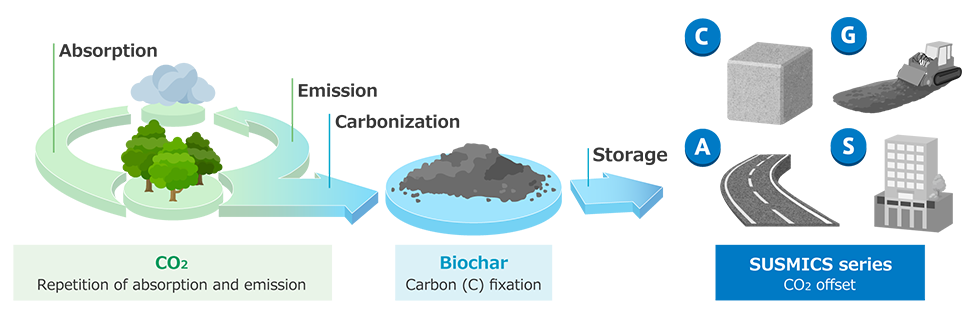

The SUSMICS (SUstainable + SMI (“charcoal” in Japanese)+ Carbon Storage) series is the collective term for environmentally-friendly construction technology that uses biochar made by carbonizing woody biomass. This technology removes CO2 from the atmosphere and realizes long-term stable carbon storage (CO2 fixation). We look here at the products in the SUSMICS series that are suitable for an extensive range of construction and civil engineering applications.

Removal of CO2 from the Atmosphere Using Biochar

Woody biomass can be considered carbon-neutral material. That is because there is balance between the amount of CO2 absorbed from the atmosphere during the course of the tree growth and the amount of CO2 emitted into the atmosphere after the woody biomass has been used. Meanwhile, when woody biomass is converted into biochar, the CO2 originally in the atmosphere is fixed in the biochar as carbon (C). That means it is possible to reduce the amount of CO2 emitted into the atmosphere (to reduce the amount of CO2 in the atmosphere). Therefore, we can call biochar a carbon-negative material.

However, simply converting woody biomass into biochar does not reduce CO2 in the atmosphere. For example, using biochar as a fuel results in CO2 being emitted into the atmosphere. All the technologies in the SUSMICS series are capable of preventing CO2 being emitted into the atmosphere by stably storing biochar in the long-term and removing CO2 equivalent to the amount of carbon in the biochar from the atmosphere.

It is possible to maximize the functionality of the SUSMICS series by selecting the applicable technology according to the application and conditions.

SUSMICS-C (Concrete)

SUSMICS-C (Concrete)

Use of Biochar to Fix Carbon in Concrete Structures

Cement, the main ingredient in concrete, emits CO2 in large amounts when it is manufactured.

Replacing part of the fine aggregate with biochar fixes carbon in concrete structures and thus realizes a substantial reduction in the CO2 emissions accompanying concrete production.

Taking advantage of the strengths of SUSMICS-C given below has already resulted in an expansion in the introduction of the technology into various construction and civil engineering sites.

Strengths

- Performance equivalent to general concrete

Various tests have been conducted on concrete made using biochar to compare it to the general concrete used in construction sites. These tests confirm that SUSMICS-C’s fresh properties and performance after hardening are equivalent to general concrete. - Highly versatile, so it enables manufacturing and construction anywhere

In addition to application to secondary concrete products, SUSMICS-C can be manufactured in general ready-mixed concrete plants. Therefore, cast-in-place is possible in the same way as with general concrete. - The amount of CO2 fixation has been reported in the National Greenhouse Gas Inventory Report of JAPAN

The amount of greenhouse gas absorbed (amount of CO2 fixation) by three types (four products) of environmentally-friendly concrete were calculated for the first time in the world in Japan’s National Greenhouse Gas Emissions and Removals in Fiscal Year 2022. The report covers SUSMICS-C as a type involving the use of biochar among the three types.

Related Links

-

-

-

News Release

On-site Application of SUSMICS-C Carbon-Negative Environmentally-friendly Concrete

- Mixed with Biochar to Store Carbon inside Concrete - -

Precisely Quantifying the CO2 Reduction Effect from SUSMICS-C

- Third-party Organization Confirms the Achievement of Carbon Negativity at an Application Site - -

Award

Winner of the Main Prize at “The 66th 2023 Ten Greatest New Products Award”

-

Minister of Land, Infrastructure, Transport and Tourism Award at the 7th EcoPro Awards

-

Double Winner at the Japan Society of Civil Engineers (JSCE) Environmental Awards

-

Pamphlet (PDF)

SUSMICS-C

SUSMICS-A*(Asphalt)

SUSMICS-A*(Asphalt)

Biochar Asphalt Pavement That Realizes Carbon Negativity

Adding biochar as a substitute for the sand in the asphalt mixture offsets the amount of CO2 emitted at the time of the asphalt mixture manufacturing with the amount of CO2 fixed by the biochar. This results in a carbon-neutral and carbon-negative asphalt mixture.

Developed jointly with THE NIPPON ROAD CO., LTD.

Strengths

- Achieves both carbon neutrality and economic efficiency

The amount of CO2 fixed by biochar (addition rate: 3%) is approximately 14 times the amount of CO2 reduced by the conventional low-carbon asphalt carbon technology of warm-mix asphalt (modified type II). This keeps down the cost to reduce 1 kg of CO2 to approximately 10% of conventional technology. - Performance equivalent to mixtures that use modified type II asphalt

The fluidity resistance of SUSMICS-A was evaluated in a wheel tracking test. The results show that SUSMICS-A has the equivalent fluidity resistance even when biochar is added compared to a normal modified type II asphalt mixture. - It is possible to carry out construction as before

It is possible to carry out construction with conventional machinery configurations without using special equipment or heavy machinery when paving.

Related Links

SUSMICS-G*(Ground Improvement Method)

SUSMICS-G*(Ground Improvement Method)

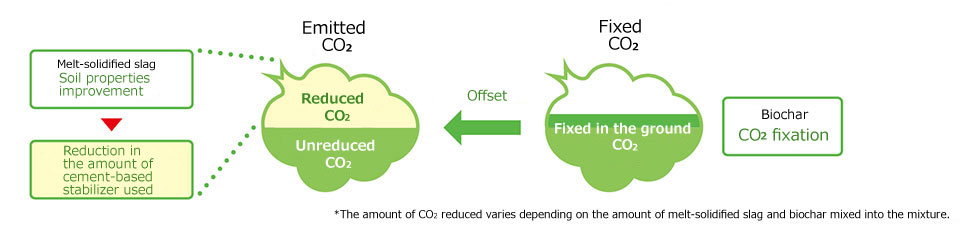

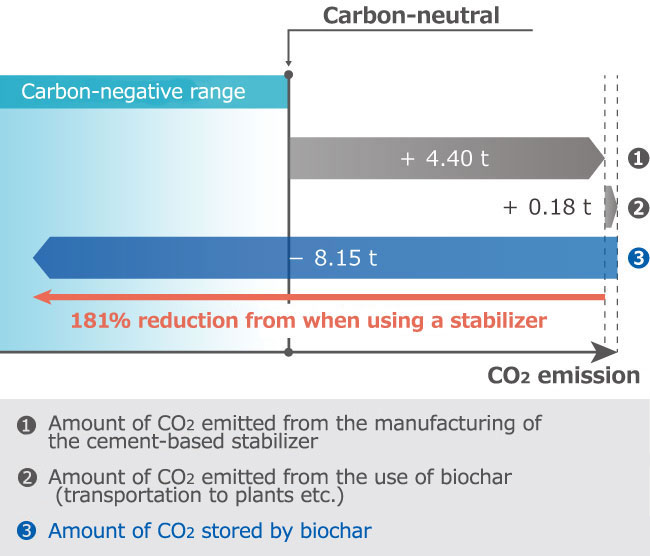

Realizing Carbon Neutrality by Mixing Biochar and Melt-Solidified Slag

This is a decarbonized ground improvement method that virtually eliminates CO2 emissions in ground improvement work employing the mixed treatment method. This ground improvement method involves evenly spreading melt-solidified slag and biochar in addition to the cement and cement-based stabilizer before mechanically mixing, stirring and compacting the mixture.

Developed jointly with Toyo Stabi Co., Ltd.

Strengths

- Improves soil properties and contributes to CO2 reduction

Mixing melt-solidified slag into soil to be improved has the effect of lowering the moisture content and raising the sand content. This improves the soil properties and increases the strength of the ground. Therefore, it is possible to reduce the amount of the cement and cement-based stabilizer used to thereby enable a reduction in CO2 emissions. - Effective use of waste

Using melt-solidified slag, made by melting general waste at high temperatures of over approximately 1,300°C and then cooling it, and sawdust, a byproduct at the time of sawing, as a biochar contributes to reducing the environmental impact. - It is possible to carry out construction as before

The ground mixing and stirring are performed using conventional construction methods. Therefore, it is possible to apply existing methods without changing the processes or the machinery used.

Related Links

-

News Release

Development of a Carbon-neutral Ground Improvement Method

- Mixing Biochar into Ground Improved Soil to Fix CO2 - -

First Application of the SUSMICS-G Decarbonized Ground Improvement Method in Actual Construction Work

- Mixing Melt-Solidified Slag and Biochar into the Ground to Realize Carbon-neutral Construction - -

Pamphlet (PDF)

SUSMICS-G

SUSMICS-S (Soil Cement)

SUSMICS-S (Soil Cement)

Ensuring Backfill Ground Quality while Reducing CO2 Emissions

Slurry-type cement treated soils, such as soil cement and fluidized soil, are made by mixing soil produced during construction or on-site soil with water and the cement that serves as the stabilizer. Adding biochar suppresses the bleeding (phenomenon involving the separation and settling of the constituent materials) at the time of solidification to thus make it possible to improve the soil quality. It also contributes to reducing the actual CO2 emissions accompanying the production of soil cement.

Strengths

- Takes advantage of high-water absorption properties to ensure quality across the depth

Adding powdered biochar with its high-water absorption properties absorbs the excess water in the soil cement that arises over time and thereby suppresses bleeding. Moreover, it has been confirmed that the quality (for example, the unconfined compression strength) across the depth is equal to or greater than that of conventional fluidized soil. - Manufacturing process and construction performance as before

It is possible to carry out manufacturing just by simultaneously adding the stabilizer and powdered biochar using existing fluidized soil manufacturing devices. The flow values in the pre-mix tests are equivalent to that of the conventional fluidized soil. There is no impact on fluidity when the mixture is poured in even in actual construction. Accordingly, it is possible to carry out construction as before. - Realizes carbon negativity

A large amount of biochar is added to the stabilizer. Therefore, it is possible to significantly reduce CO2 (carbon negativity).

Related Links

-

-

-

News Release

Development of SUSMICS-S Environmentally-friendly Backfill Ground Material That Uses Biochar

- Storing Carbon Fixed to Biochar in the Ground and Improving the Construction Quality - -

On-site Application of SUSMICS-S Carbon-negative Environmentally-friendly Backfill Ground Material

- Mixing Biochar and Storing Carbon in the Ground - -

Pamphlet (PDF)

SUSMICS-S