Takes on the challenge of robot controlling that will transform construction worksites

The construction industry is faced with the challenges of activities to improve productivity and secure future workers. The Robotics Research Area brings together a variety of cutting-edge technologies, including 3D printing for construction, which contributes to labor savings at construction worksites.

Example of Tests and Achievements

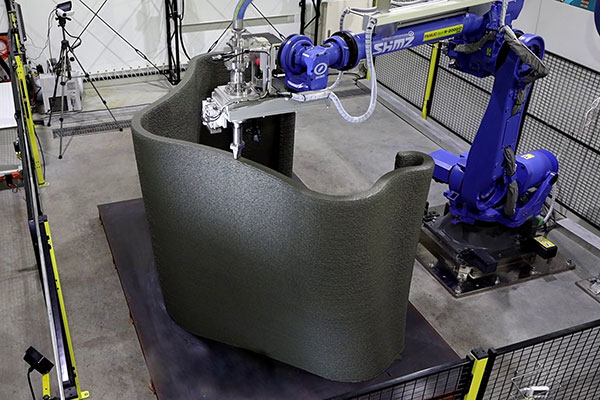

Construction 3D Printing

LACTM, our proprietary fiber reinforced cement material for 3D printing enables direct printing of concrete from non-structural to structural components.

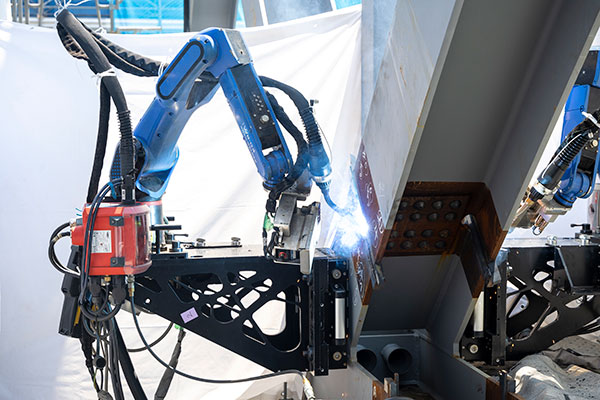

Metal 3D Printing

Aluminum is laminated by welding robots to form structures. Taking advantage of the flexibility and lightness of the formation, we are working on manufacturing components for construction and space rockets.

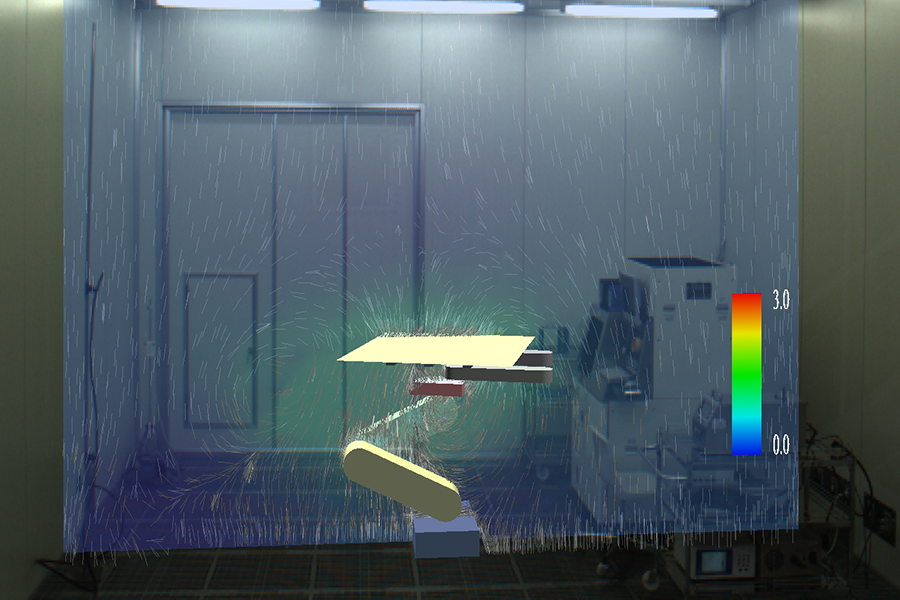

Shimz Smart Site

next-generation production system

Linked to BIM, a 3D model of the building, AI-equipped autonomous construction robots work in collaboration with humans.

- Robo-Welder: welding robot

- Robo-Buddy: multi-purpose construction robot

- Robo-Carrier: automated conveyor robot