Building the Future with Renovashi Bridge Renewal Initiatives

Tomei Expressway (Specified Renewal) Sugegaya Viaduct Deck Replacement Project

Expressways play a vital role in supporting everyday life and economic activity, yet many were constructed during Japan’s period of rapid economic growth. Over time, aging structures and rising traffic volumes have led to increasing deterioration. To address this, the nationwide Expressway Renewal Project is underway, reconstructing roads to deliver performance equal to or better than when they were first built.

Since 2018, Shimizu has undertaken bridge renewal projects under the slogan “Renovashi” (derived from “Renovation” and “Hashi” [meaning bridge]) and has completed 18 projects to date. We have also been developing innovative technologies to enhance productivity while reducing labor and manpower needs.

This section highlights project examples we have delivered, along with the new technologies and equipment introduced through these efforts.

■Project Example

①Deck Replacement Using Half-Section Construction: Sugegaya Viaduct

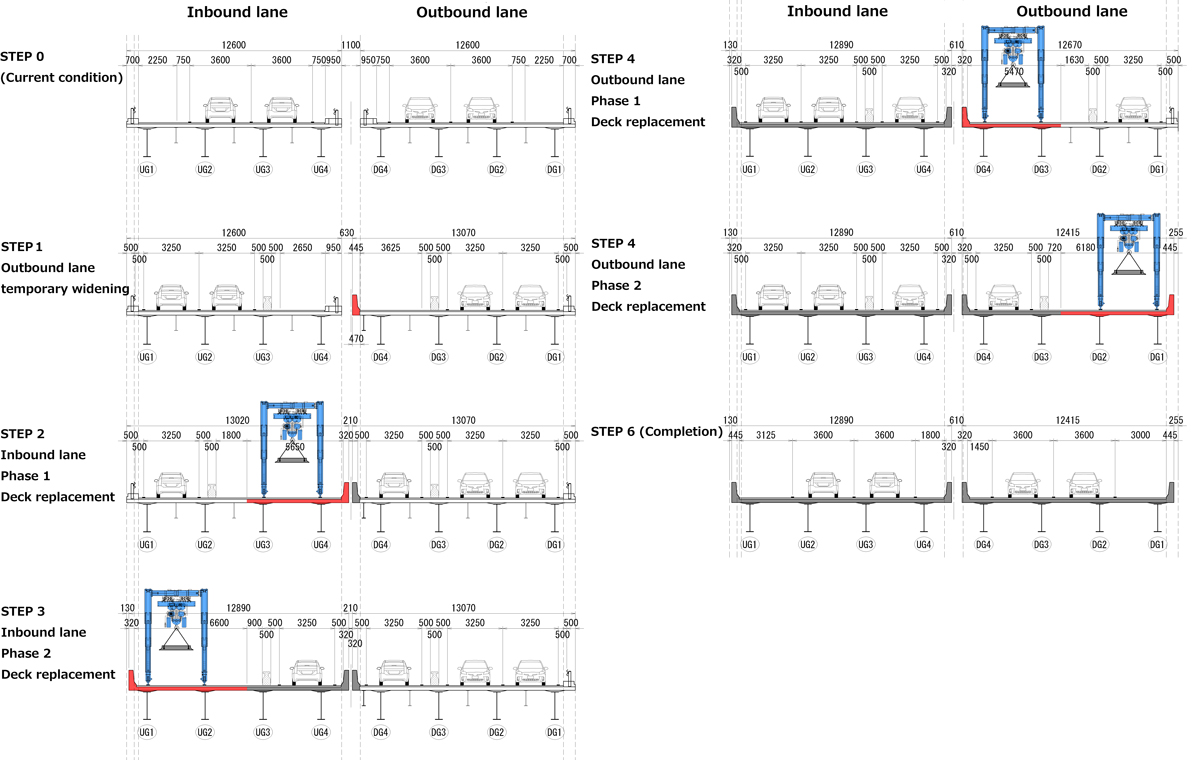

One example is half-section construction, where the deck is replaced by dividing it across the width of the bridge, a method that has seen growing use in recent years. The Sugegaya Viaduct, a 270-meter-long structure on the Tomei Expressway between the Fukuroi and Kakegawa interchanges, has been in operation for over 50 years. While partial repairs and reinforcements had been carried out over the years, deterioration had begun to affect the main bridge structure itself, prompting the decision to undertake large-scale renewal work.

The construction zone carries more than 30,000 vehicles during the day, raising concerns of congestion if lanes were reduced during the work period. To address this, Shimizu implemented concrete deck replacement using a half-section construction method, allowing the full four lanes of traffic to remain open while the work proceeded. Because this method provides workspace equivalent to only about one lane, large cranes cannot be used. Instead, heavy components, such as precast decks, were lifted into place with a gantry erection machine capable of handling loads of up to 15 tons.

Alongside the deck replacement, seismic reinforcement of existing piers, strengthening and repainting of steel girders, and replacement of bearings were also carried out. By combining these efforts, the project renewed the bridge as a whole and contributed to extending the service life of vital, safe, and durable infrastructure.

Construction step video

- Project Name

- Tomei Expressway (Specified Renewal) Sugegaya Viaduct Deck Replacement Project

- Location

- Kakegawa City (Agehari) to Fukuroi City (Yamashina), Shizuoka Prefecture

- Client

- Central Nippon Expressway Company Limited

- Contractor

- Shimizu Corporation / FaB-Tec Japan Corporation Joint Venture

- Construction period

- December 2021 – October 2025

- Structure & Scale

-

Structural Type Steel three-span continuous non-composite plate girder bridge x 3 (both directions) Bridge Length 270.0 m Effective Width 10.95 m (before renewal) > 12.13 m (after renewal) Deck Replacement 5,659 m2 Deck Surface Overlay 1,072 m2 Steel Girder Reinforcement 226t Repainting 15,921 m2 Bearing Replacement 72 units

②Deck Replacement on an Urban Expressway: Hanshin Expressway Route 3 Kobe Line

Another example is a deck replacement project carried out using specialized methods.

The section of the Hanshin Expressway, Route 3 Kobe Line, between the Kyobashi and Maya interchanges, located in central Kobe, had been in service for more than 50 years. With sharply rising traffic volumes and the trend toward larger vehicles, damage had become evident in the decks, pavement, and expansion joints. To address this, large-scale renewal work was conducted, resulting in a full road closure from May 19 to June 7, 2023. Shimizu was responsible for deck replacement on the S391 bridge (outbound lane) of the Kobe Line.

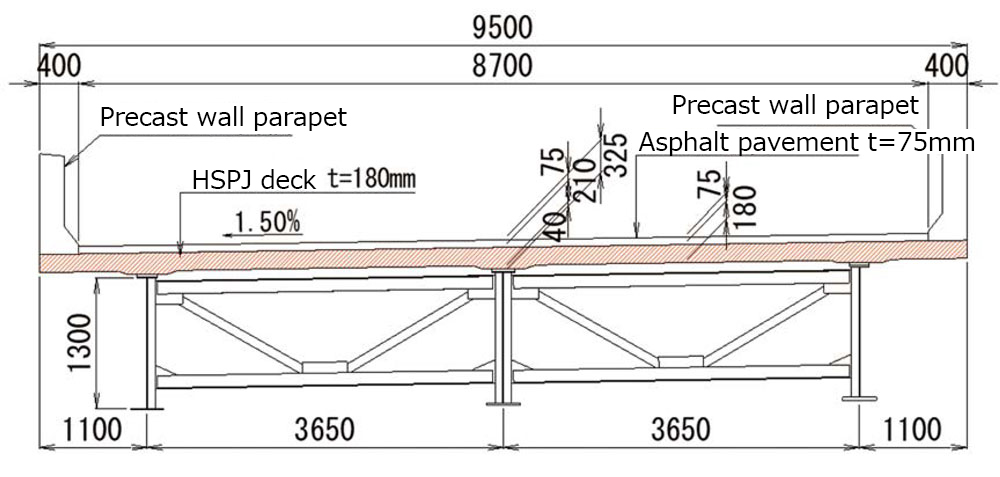

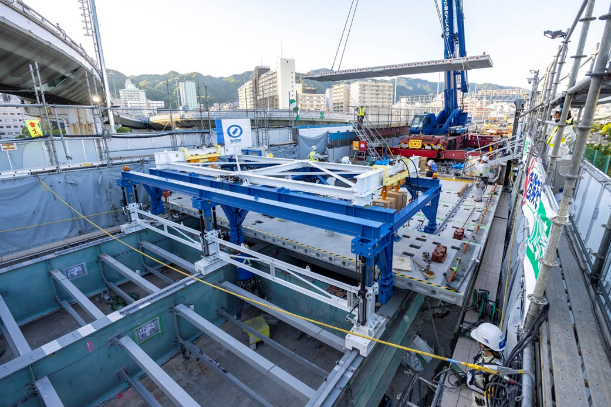

The project required both a shortened schedule and execution under the severe constraints typical of urban expressways. To meet these demands, Shimizu applied innovative technologies, including the HS Prestress Joint Deck (HSPJ deck*) and advanced deck erection machinery, which enabled rapid replacement under challenging urban conditions. This project was recognized with the 2023 Technology Award from the Japan Society of Civil Engineers and the 5th Civil Engineering Award from the Japan Federation of Construction Contractors in 2024.

*The HSPJ deck is a new precast deck technology jointly developed by Hanshin Expressway Company Limited, Shimizu Corporation, Unytite Inc., Sumitomo Electric Industries, Ltd., and Showa Concrete Industry Co., Ltd.

- Project Name

- Large-Scale Concrete Deck Replacement Project (2022-2-Kami)

- Location

- Isogami-dori, Chuo-ku, Kobe City, Hyogo Prefecture

- Client

- Hanshin Expressway Company Limited

- Contractor

- Shimizu Corporation

- Construction period

- August 2022 – October 2023

- Structure & Scale

-

Structural type Steel simple composite plate girder bridge for live load Bridge length 21.0 m Total width 9.5 m Deck work 183 m2 (HSPJ deck) Parapet work 42 m (precast wall parapet) Main girder reinforcement work 3.5 t

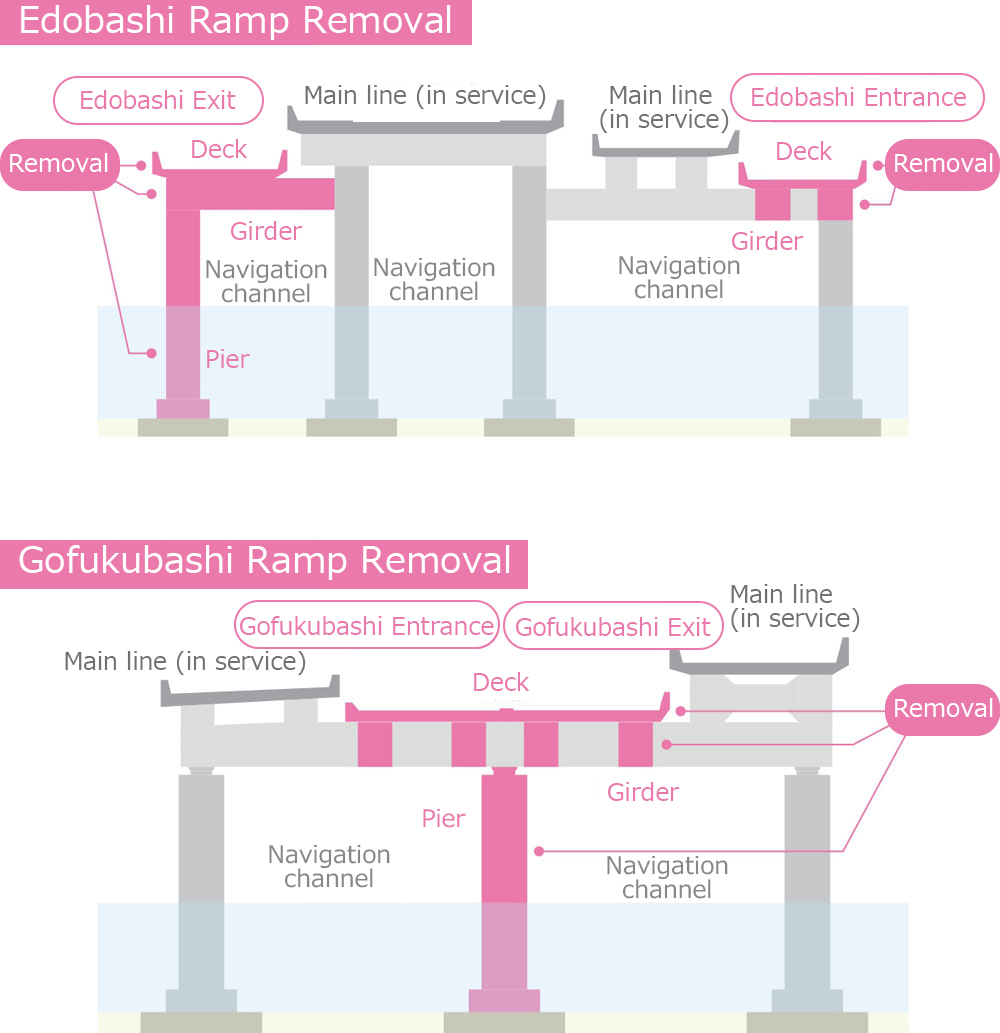

③Demolition Work on an Urban Expressway: Removal of the Gofukubashi and Edobashi Ramps, Metropolitan Expressway Inner Circular Route

The next example is bridge demolition work undertaken in Nihonbashi, Tokyo.

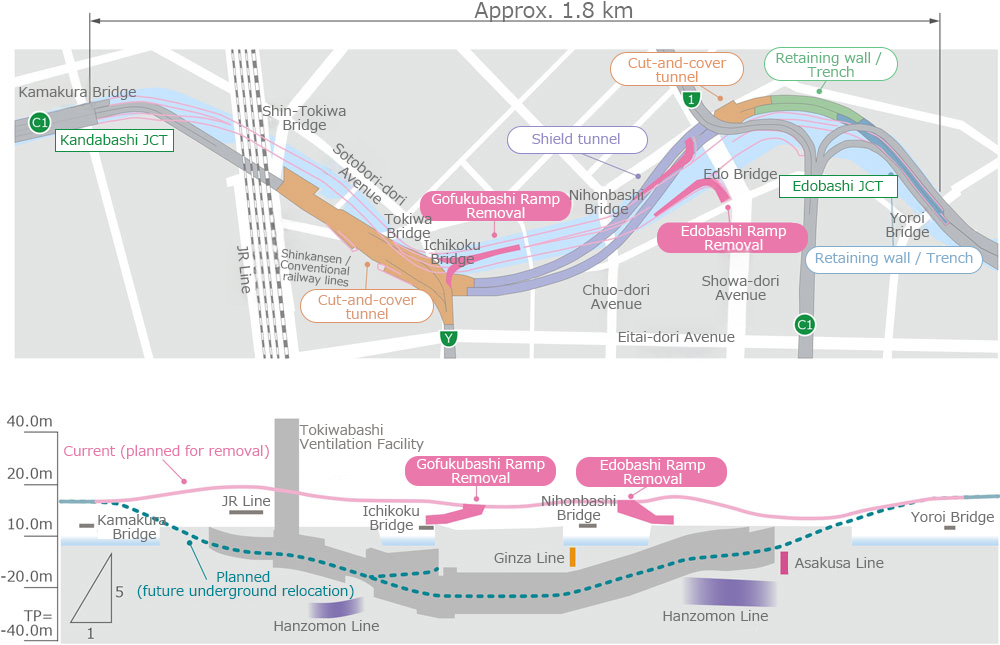

The Metropolitan Expressway Inner Circular Route

, which crosses above the Nihonbashi River, had been in service for more than 60 years. With about 100,000 vehicles using the route each day, the structures had suffered extensive deterioration, making large-scale renewal essential. To address this, an underground relocation project is now underway between Edobashi JCT and Kandabashi JCT, in coordination with the broader redevelopment of the Nihonbashi River area. As preparatory work for the relocation, Shimizu carried out the demolition of the Gofukubashi and Edobashi ramp bridges in advance, enabling the removal and replacement of pier foundations that would otherwise interfere with the future underground tunnel.

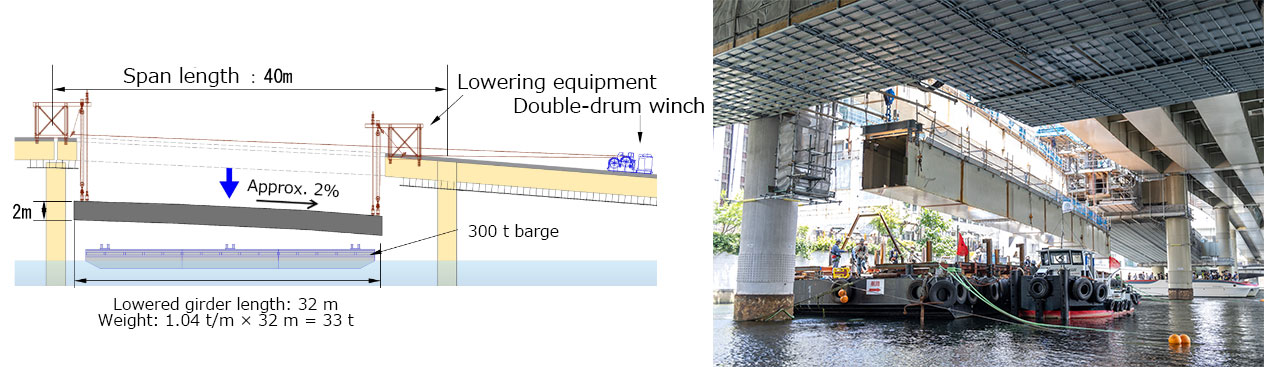

The demolition work involved approximately 6,200 tons in total, including bridge decks, main girders, piers, and ancillary structures, requiring the use of multiple advanced technologies. Before construction began, a detailed assessment was conducted to evaluate potential impacts on the mainline bridge. Throughout the work, deformation was closely monitored in real-time.

Concrete deck slabs and wall parapets were cut into large blocks for removal, with the newly developed Deck Cool Cut Method also tested in certain areas. Steel girders were dismantled by suspending and lowering entire large blocks using barges. Despite the severe working conditions, including being adjacent to an operating expressway and above the Nihonbashi River, which remains active for river traffic, the project was completed safely and on schedule. It was honored with the 2024 Technology Award from the Japan Society of Civil Engineers and the 2024 Zenken Award from the Japan Construction Engineer’s Association.

- Project Name

- (Revised) Metropolitan Expressway Inner Circular Route (Nihonbashi Section) Gofukubashi and Edobashi Ramp Removal Project

- Location

- Nihonbashi to Nihonbashi Hongokucho, Chuo-ku, Tokyo

- Client

- Metropolitan Expressway Company Limited

- Contractor

- Shimizu Corporation and JFE Engineering Corporation Joint Venture

- Construction period

- November 2020 – February 2024

- Structure & Scale

-

(Gofukubashi Ramp) (Edobashi Ramp) Structural type Steel deck simple box girder bridge

Steel two-span continuous non-composite twin main box girder bridge (both ramps)Steel two-span continuous non-composite twin main box girder bridge (both ramps) Deck removal 640 m3 740 m3 Steel girder removal 880 t 550 t Steel pier removal 3 columns 4 columns

■New Technologies and Equipment

The following section introduces the renewal technologies that Shimizu has developed and adopted to shorten construction schedules, reduce costs, and improve durability, along with newly introduced equipment.

◆Developed Technologies

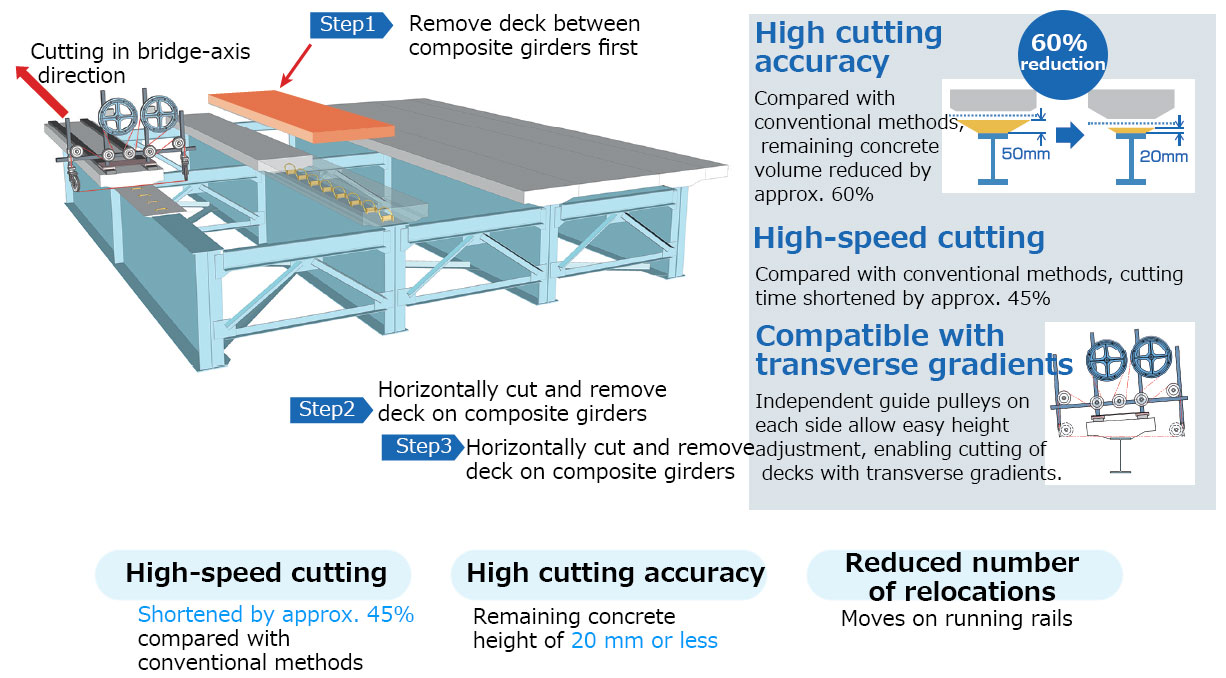

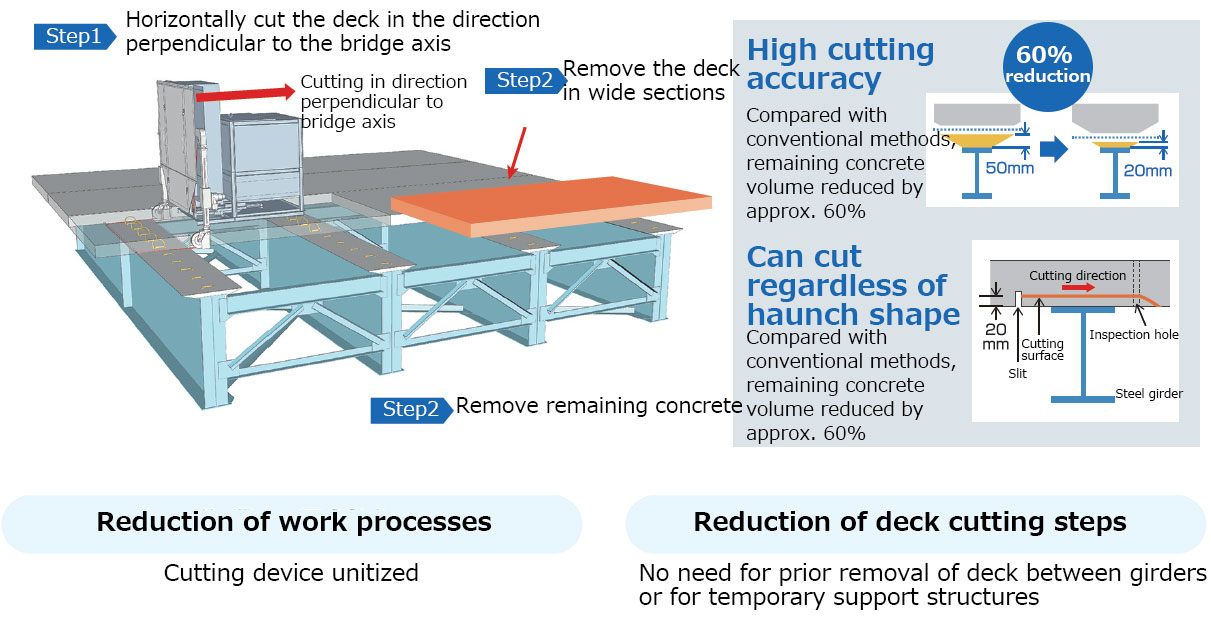

①Cutting Technology for Existing Decks – Double Wire Saw Method and Deck Cool Cut Method

To improve efficiency in removing composite girder concrete decks, Shimizu developed two cutting methods: the Double Wire Saw Method and the Deck Cool Cut Method. Both reduce cutting time by 45 percent, deliver higher cutting precision, and can be applied to either wet or dry cutting. Depending on site conditions, such as the shape of the girder or the presence of haunches, the two methods are applied selectively.

Double Wire Saw Method

This method utilizes a cutting device that combines a high-performance wire saw with two drive pulleys and a traveling carriage that runs on rails. Because the device can move along the rails, the number of times the cutting equipment needs to be assembled and dismantled is significantly reduced.

Deck Cool Cut Method

This method utilizes the unit-type cutting device, “Foundation Structure Cool Cut,” which is capable of both horizontal and vertical cutting, to horizontally cut concrete decks on composite girders. It eliminates certain construction steps and can accommodate a wide range of haunch shapes.

②Joint Technology for Precast PC Decks

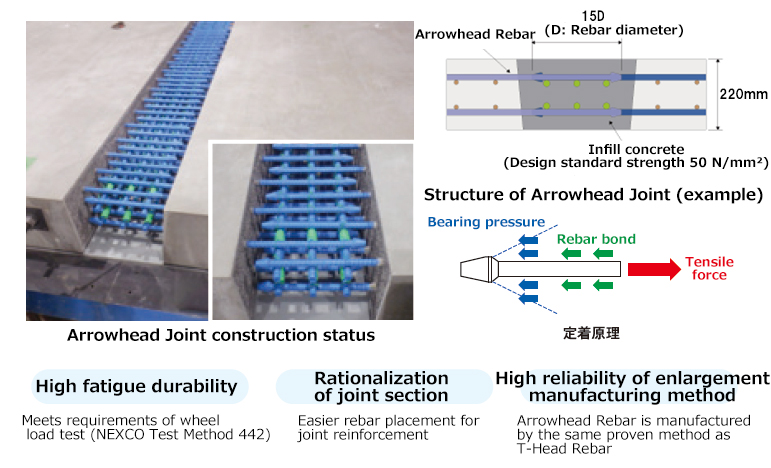

Arrowhead Joint Method

For connecting precast prestressed concrete (PC) decks in the bridge axis direction, Shimizu developed the Arrowhead Joint Method, which uses “Arrowhead Rebars,” mechanical anchorage rebars with arrowhead-shaped anchors at their ends. The anchors are integrally formed with the rebar body, allowing them to be compact in size. This enables the design of thinner decks and streamlines reinforcement work.

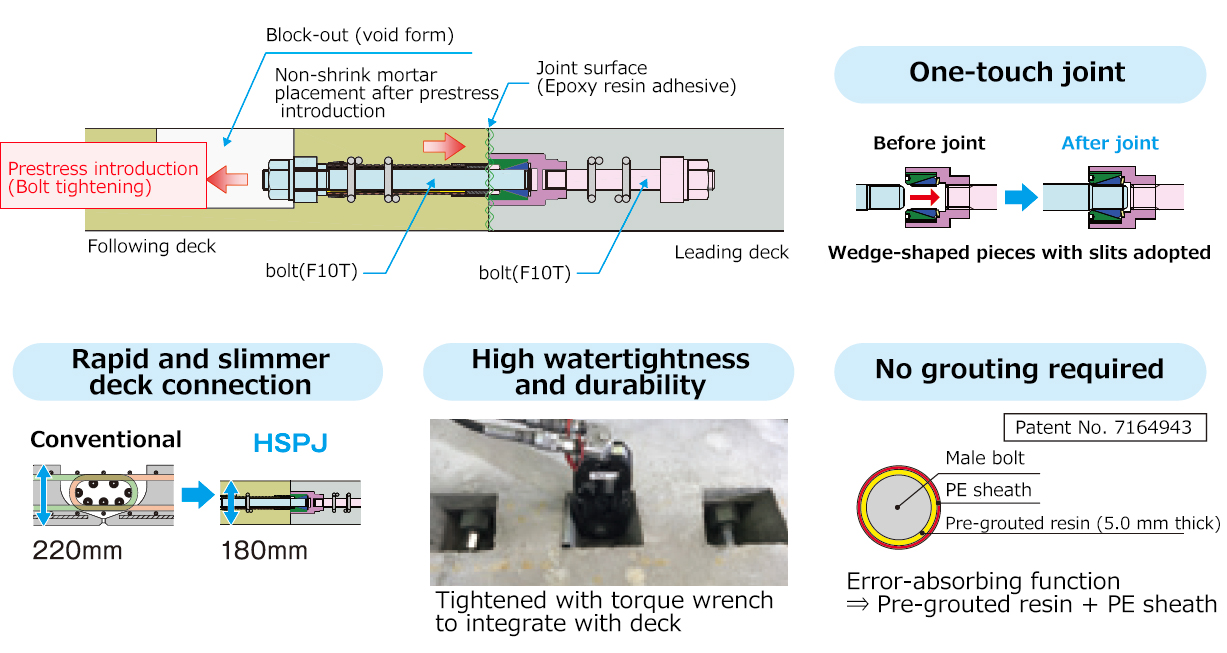

HS Prestress Joint (HSPJ) Method

The HSPJ Method is a joining technique for precast decks that utilizes a newly developed joint. Because it allows deck thickness to be maintained at the same level or thinner than before renewal, it avoids impacting the existing structure. The one-touch connection also enables rapid installation.

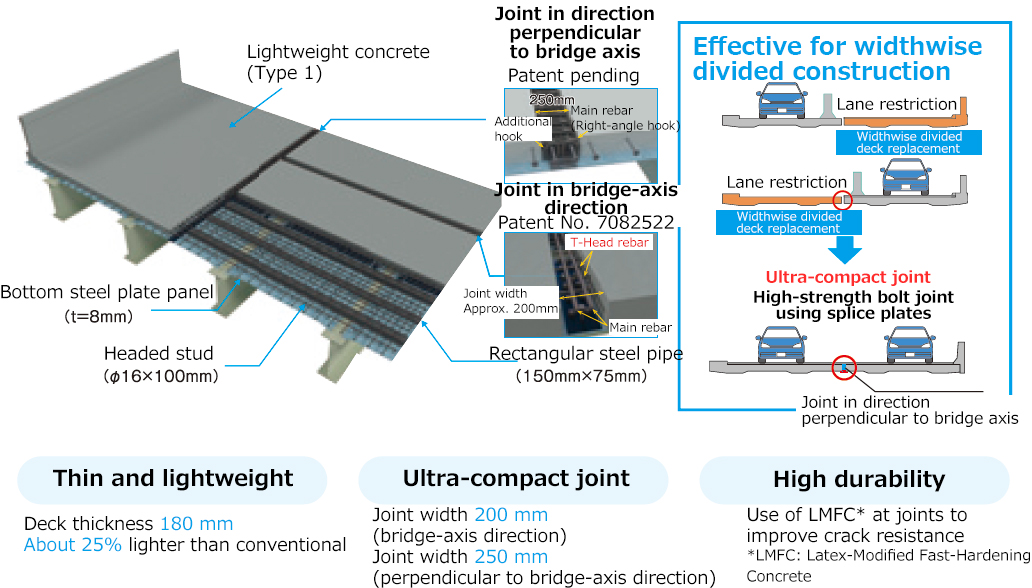

SLaT-FaB Deck

The SLaT-FaB Deck is a precast composite deck that incorporates T-head rebar at the joints. The bottom steel plate panels are connected using splice plates and high-strength bolts, making it highly effective for widthwise divided construction during deck replacement projects.

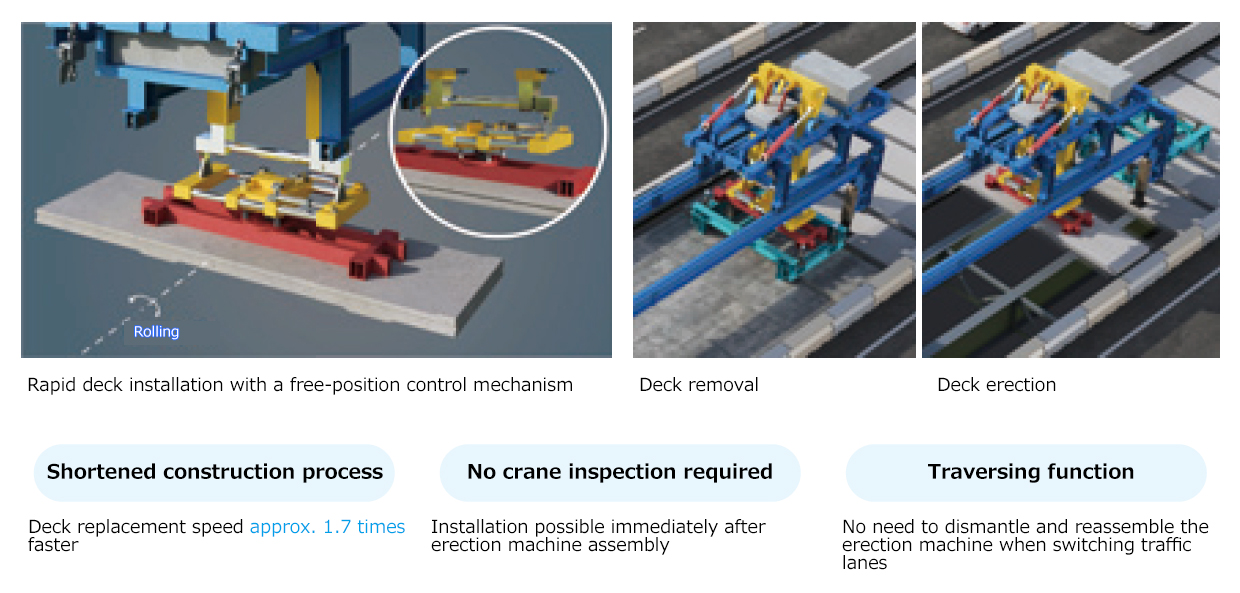

③Half-Section Deck Erection Method: Grabbing Erector Method

Grabbing Erector Method

The Grabbing Erector Method is a deck replacement technique that performs both the removal of deteriorated decks and the erection of new decks with a single device. It enables half-section construction, allowing for deck replacement in widthwise divisions while maintaining the existing number of expressway lanes. With its gripping mechanism capable of controlling deck positioning in three dimensions, the replacement speed is approximately 1.7 times faster than conventional methods. Additional features include exemption from crane inspections, since the gripping mechanism is not classified as a crane, and a traversing function that eliminates the need to remove the equipment when switching lanes.

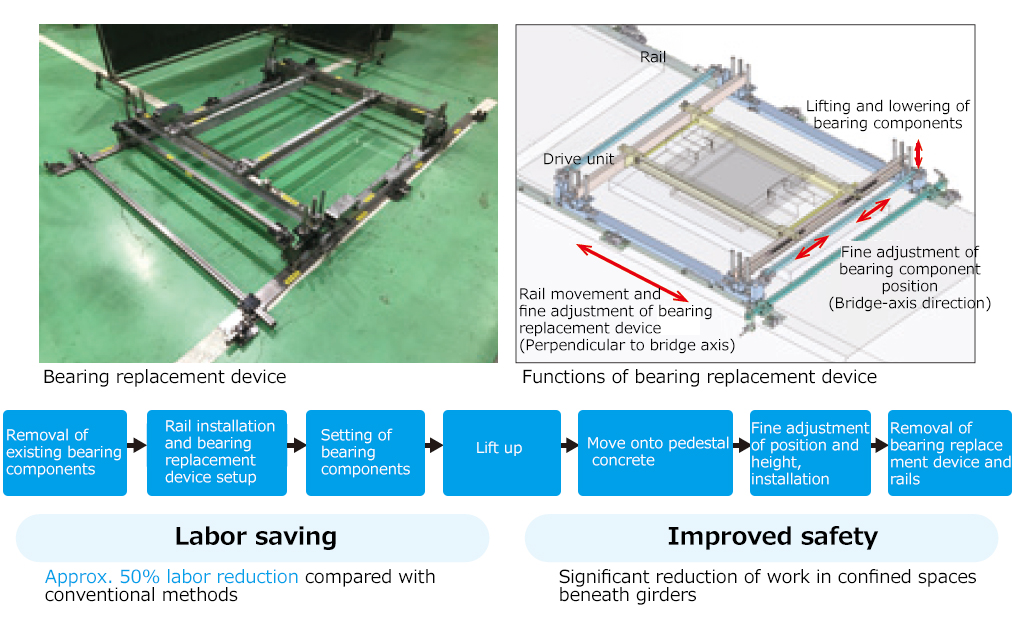

④Labor-Saving Technology for Bearing Replacement

This device is designed to simplify the replacement of bearing components in the confined spaces beneath girders. By applying it to bearing replacement work during deck renewal and seismic reinforcement projects, it achieves reduced manpower requirements, shorter schedules, and enhanced safety.

◆Introduced Technologies

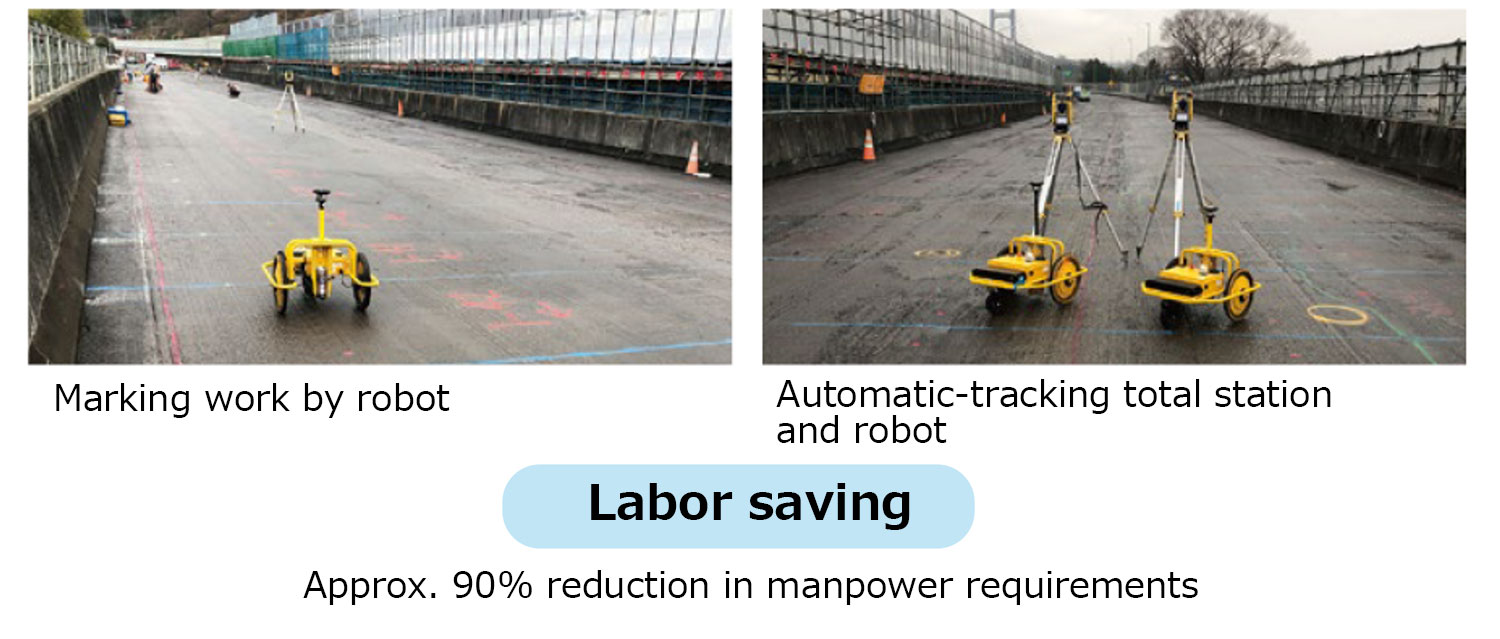

Existing Deck Cutting and Surveying Technology: Automatic Marking Robot

To enhance efficiency in marking out cutting lines on existing decks, Shimizu introduced the automatic marking robot “Tiny Surveyor.” The system increases productivity in marking operations by approximately 90 percent.

◆Introduced Equipment

Dedicated Deck Production Line

At the Nagareyama Plant in Chiba Prefecture, operated by SC Precon Co., Ltd., a Shimizu Group company, a new concrete deck production line using the pretension method has been established. This ensures a stable supply of components to construction sites while reducing procurement costs. The plant is also capable of manufacturing DAK-type precast wall parapets.

■Building the Future with Renovashi

Drawing on our proven track record and experience, Shimizu is pursuing further improvements in productivity, reductions in labor and manpower, and shorter schedules for bridge renewal projects. Through expressway renewal and other bridge renewal projects, we remain committed to building safe, reliable infrastructure that helps to “building the future.”

The information posted here is the current information on August 5, 2025.

Please be aware that this information may have changed by the time you view it.