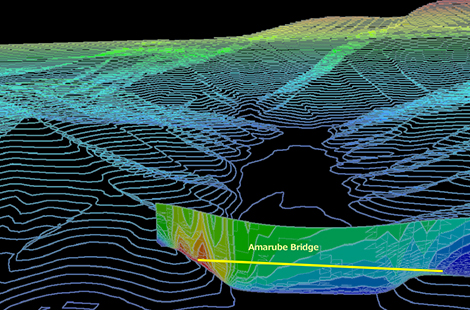

Building Lives and Protecting CommunitiesAmarube Bridge,

Working on a Civil Engineering Heritage that Will Last 100 Years

First-generation Bridge Loved as a Tourist Attraction

Amarube Bridge between Yoroi Station and Amarube Station on the JR San’in Main Line. Once made of steel, the name Amarube Steel Bridge is familiar. A masterpiece of a bridge in Japan that had also been chosen as a modern era civil engineering heritage, the Amarube Bridge was given new lease on life in 2010, roughly one century after it was built during the Meiji period (1868 – 1912).

The firm chosen to rebuild it was Shimizu, with its definitive record in civil engineering technology. The project was driven forward with historically unprecedented construction techniques, overcoming the harsh natural conditions. The end goal was to build a civil engineering heritage that would last 100 years and that rivaled the original bridge.

Long-desired Rebuilding with the Aging “Modern Civil Engineering Heritage”

Before it was rebuilt, the steel bridge was a high trestle bridge composed of steel frame piers that widened toward the ends. This was the first bridge of this shape and size in the East at that time, and the magnificent form overlooking the Japan Sea had captivated railroad fans and many other people.

However, revision of the restrictions on passage to a maximum wind speed of 20 m/s due to an accident in 1986 in which a train fell off the bridge substantially increased delays and suspension of train service. In 2002, the decision to rebuild the bridge was ultimately made in the interest of stable train service and also due to the progressing deterioration of the bridge.

It was the largest steel-frame trestle bridge in Asia at the time.

A Battle with Nature, 40 Meters Above Ground

The bridge was rebuilt with collective civil engineering technology of Shimizu with the goal of creating a civil engineering heritage that would last 100 years. The problem from the outset was performing construction in the harsh natural environment bordering the Japan Sea.

The winter was especially harsh with fierce seasonal winds in addition to accumulating snow. Working on the bridge at 40 meters above ground entailed an even fiercer battle with the wind, necessitating extreme caution. Three-dimensional wind direction and speed monitoring equipment was installed at the site to overcome this characteristic difficulty of Amarube. The data obtained was transmitted to the Institute of Technology in real time. We analyzed the wind conditions and conducted simulations, thereby ensuring a safe construction process, and contributing to reliable train service.

The bridge spans an area where the winds converge and blow fiercely.

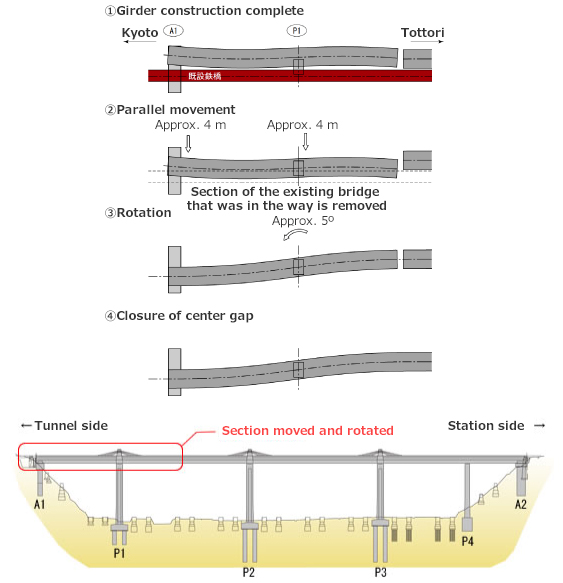

Bridge Girder Movement and Rotation Construction Method Unprecedented in Japan

In addition to the harsh natural conditions, the biggest problem facing the Amarube Bridge project as a whole was shortening the length of train service interruption as much as possible because the bridge was an important means of transportation for local residents and was also a resource for tourism. Shimizu therefore built the new bridge parallel to the old bridge.Shimizu devised a groundbreaking construction method to align the line placement leading up to the tunnel entrance, a connection point that could not be changed.

his was achieved by producing an S-shaped bridge girder, and using hydraulic jacks and other equipment to move and rotate it.For that reason, 220 meters of the bridge’s total 310-meter length formed a straight line from the west end on the Tottori side, and the 90 meters on the east end, on the Kyoto side, bent in a gradual S-curve.

Train service was maintained uninterrupted as much as possible.

That was the highest priority goal in the project, which stretched on for three and a half years.

(new bridge)

Massive Bridge Girder Moved 40 Meters Above Ground Was 90 Meters Long and Weighed 3,800 Tons

The new bridge was built right next to the old bridge, and moved into the specified position.

The only way to accomplish that for the Amarube Bridge was to move a massive bridge girder weighing 3,800 tons and 90 meters long sideways in a parallel motion by four meters in the air, 40 meters above ground, and then rotate it by 5.2 degrees. To successfully accomplish such civil engineering work that was unprecedented in both scale and construction method, we created a precision 1:10 scale model and performed repeated trials, analyzing the bridge movements in detail, in advance. The challenge was to leave nothing to chance.

The actual construction was completed in a short period that only interrupted train service for 26 days, including the parallel movement and rotation of the bridge section, and construction of the railroad track. We were able to proceed safely on all aspects of construction within the scope of advance simulation, and the preparation for the difficult work led to actual success.

Beginning the Race

Embarking on a Civil Engineering Heritage that Will Last 100 Years

The sought after rebuilding of the Amarube Bridge was finally completed on August 12, 2010, three and a half years after construction began. The new slender, linear design was created in the image of the former bridge that had been loved by people over the course of a century. Equipping the bridge with walls that serve as windbreaks on both sides has made it possible for train service to run up to wind speeds of 30 meters per second. The windbreaks are made of clear acrylic, enabling passengers to enjoy the view of the beautiful Japan Sea from the train windows as they always have.

Aiming for the Amarube Bridge to become civil engineering heritage that would last 100 years the instant it was completed, we began to trace out a new history.

for the new Amarube Bridge on August 12, 2010

The information posted here is the current information on September 1, 2017.

Please be aware that this information may have changed by the time you view it.