Work Style Reforms at Construction Sites Actions for “Create a New Normal” at Construction Sites

As the awareness of viruses among people heightens due to COVID-19, bringing about changes in their behavior, Shimizu is striving to adapt to changes in the environment in corporate activities and in workstyles, and sees the need to innovate to adjust to new conditions and a new normal.Shimizu is currently implementing such new normal activities company-wide.

We are revising operating processes one by one to achieve higher productivity and performance.

Below, we start by introducing an example of a Shimizu construction site targeting the new normal.

Promote Operational Efficiency by Checking and Circulating Paperless Drawings

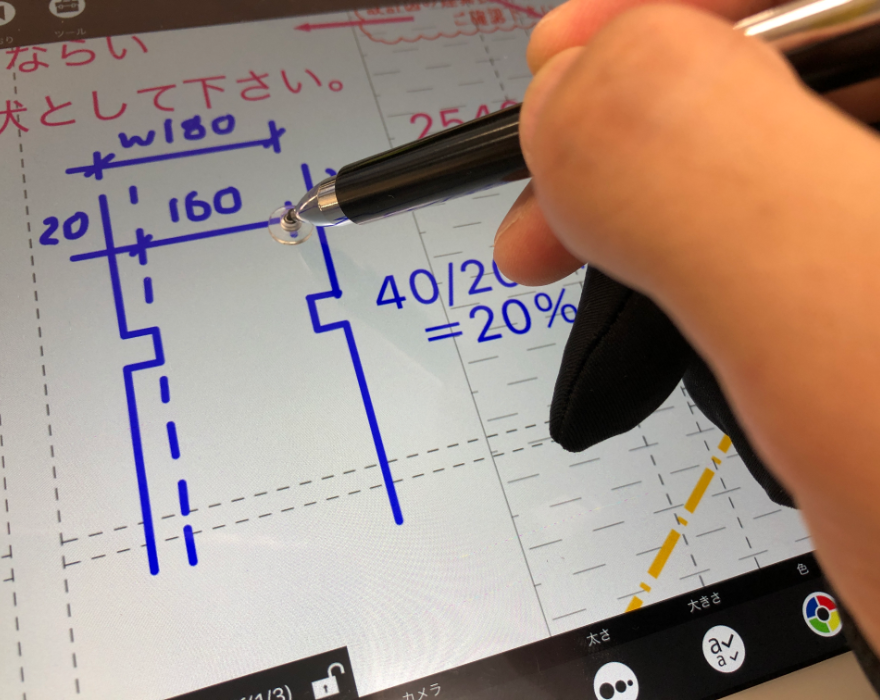

In the past, the process of checking drawings has been to print them out on paper, write in the necessary information, and circulate them to the people involved at each location to confirm them. However, the expansion in telecommuting has made it difficult to circulate paper media and raised the issue of avoiding the risk of losing them. We are therefore using the TerioCloud software to check and confirm drawings without paper. By using PDF and CAD data loaded in this software, it is possible to perform the same work on a computer as writing on a paper drawing.

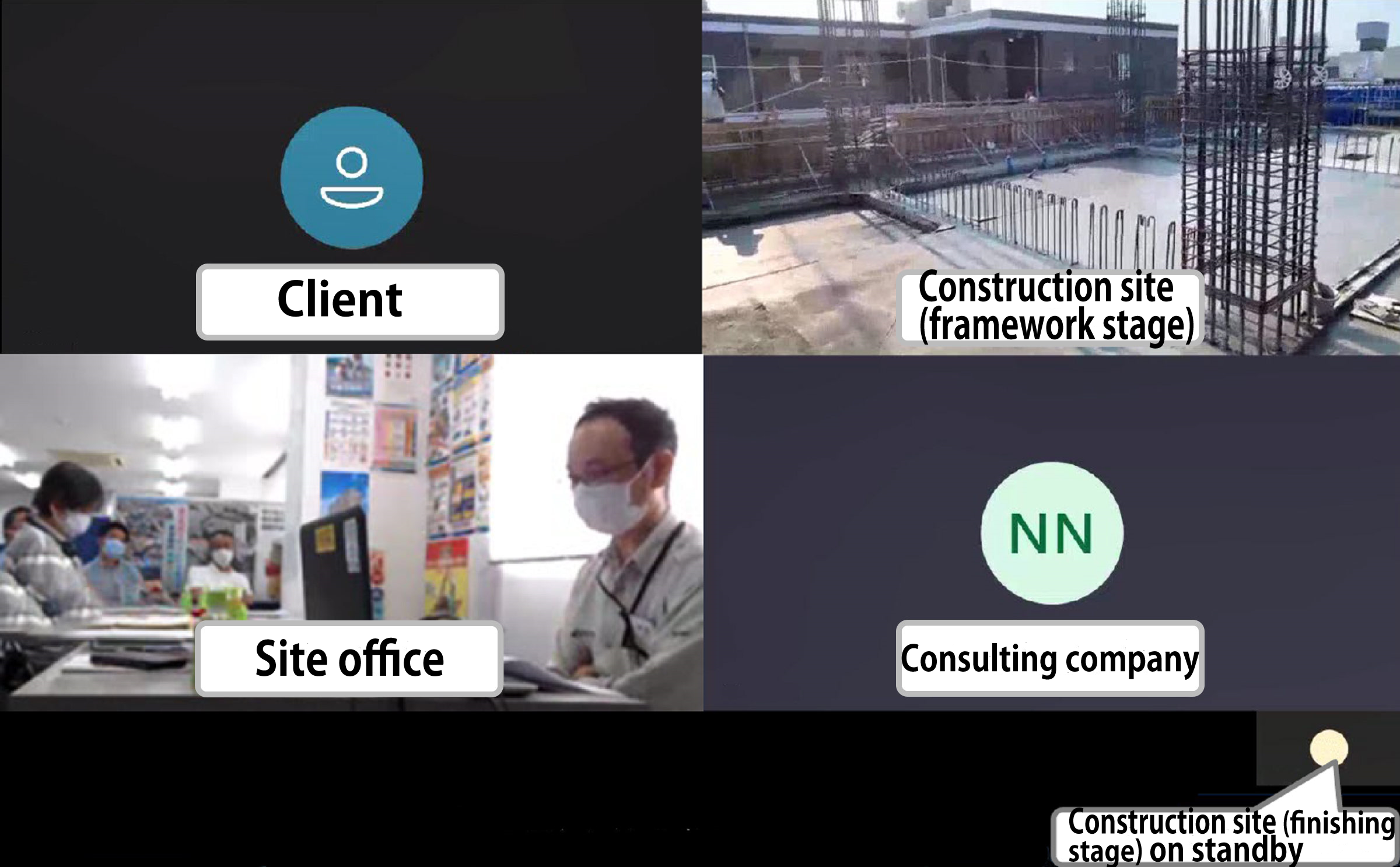

The software can be used from an iPad or other tablet device and data can be shared on a cloud. This enables staff members in multiple divisions such as the construction site, the design division, and corporate staff members to check the drawings. Approvals are also computerized so this is advancing our efforts to go paperless.

Drawing checking is now possible by sharing drawings with all parties concerned on TerioCloud

The "Triplet-lens Camera Rebar Arrangement Inspection System" Enables Efficient Reinforcement Inspection by Remote Control

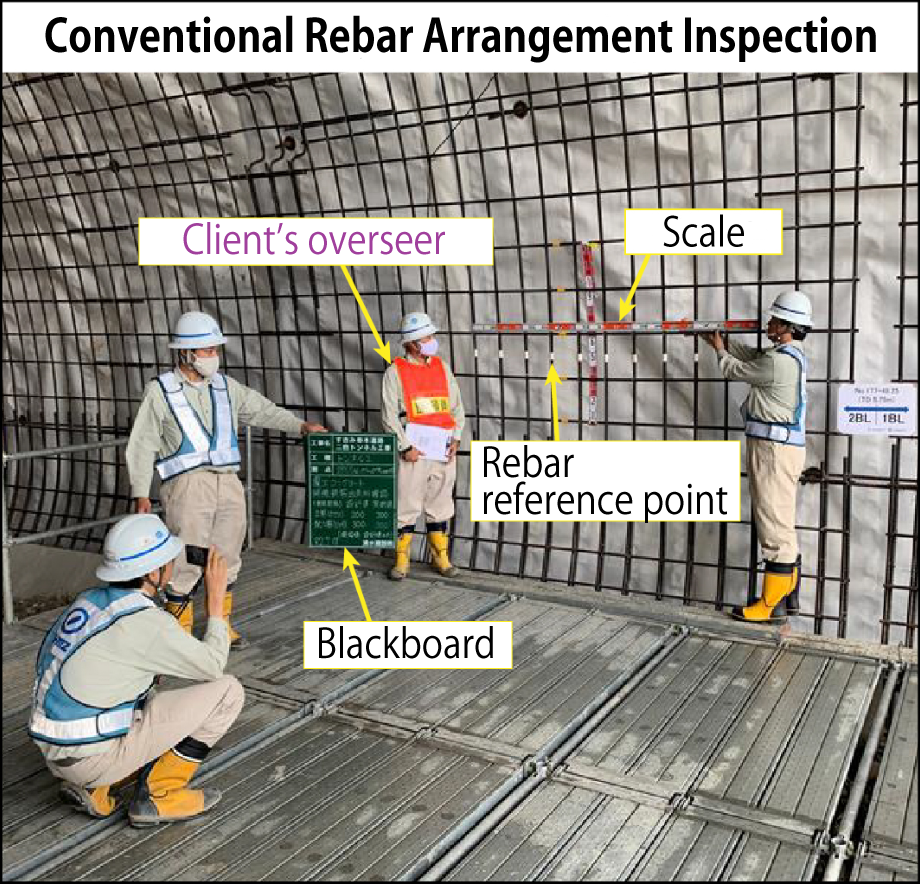

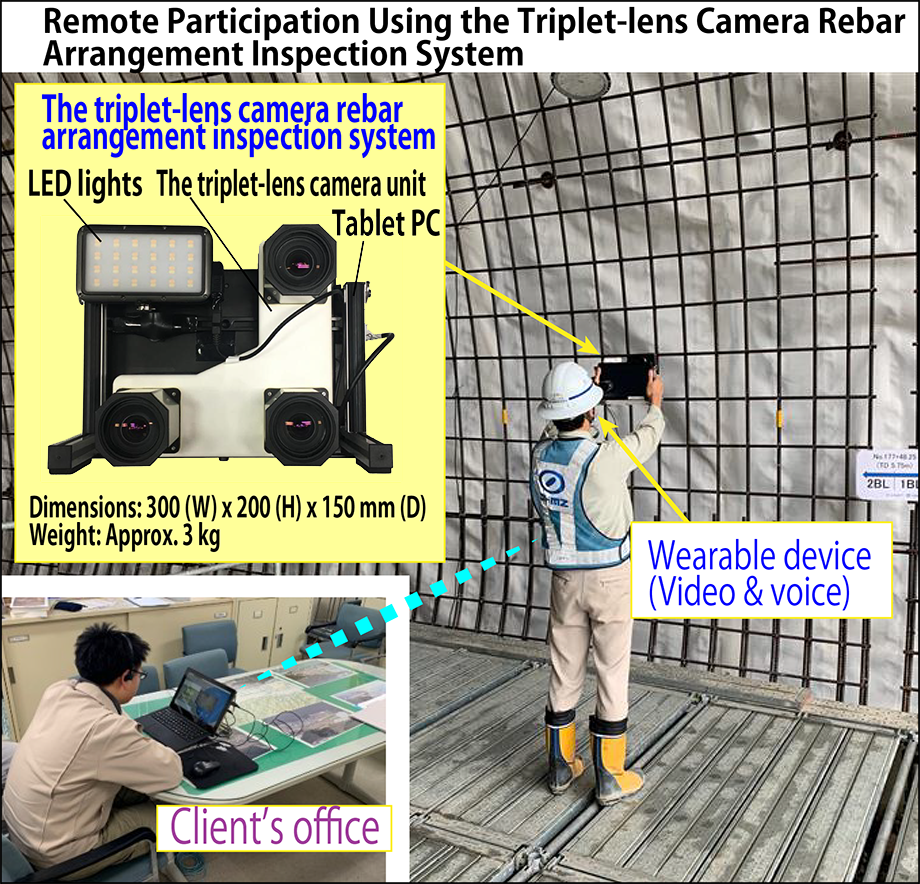

The rebar arrangement inspection is an important quality control process that is essential for guaranteeing the quality of concrete structures. The mainstream method relies on manual inspection and the substantial work involved was a problem. Shimizu and Sharp Corporation jointly developed the triplet-lens camera rebar arrangement inspection system to improve the efficiency of rebar arrangement inspections. This system was adopted twice by the public offering of the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) through the Cabinet Office Public/Private R&D Investment Strategic Expansion PrograM (PRISM), and was used commercially in two construction projects ordered by the Tohoku Regional Development Bureau.

When a rebar arrangement is photographed, camera data from three angles is obtained. The system performs a 3D analysis and automatically calculates rebar diameter, average intervals, etc. in only seven seconds. It then produces an inspection record. This one system is capable of performing a series of steps in the workflow.

This system is also drawing interest for the infrastructure sector DX* that MLIT is pursuing. When two-way communication is assembled by using this system together with a wearable device, the number of inspectors at the construction site can be reduced to one, and the inspection time can be reduced to one-third or less. Measurement results can be shared via a cloud. Remote rebar arrangement inspections are also effective as an infection prevention measure.

*DX:An abbreviation of digital transformation. The concept is to transform the lives of people for the better through the widespread use of advanced digital technology.

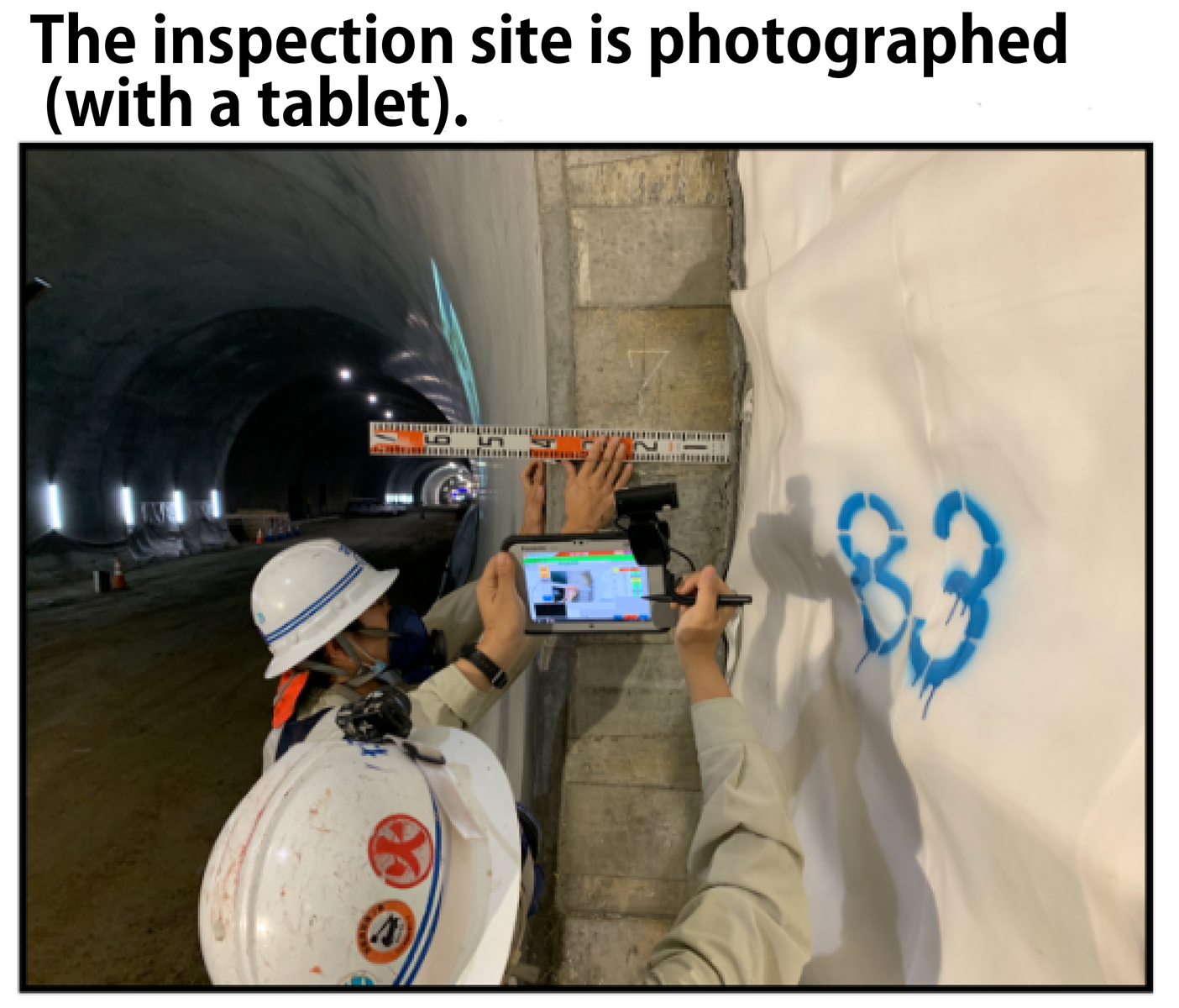

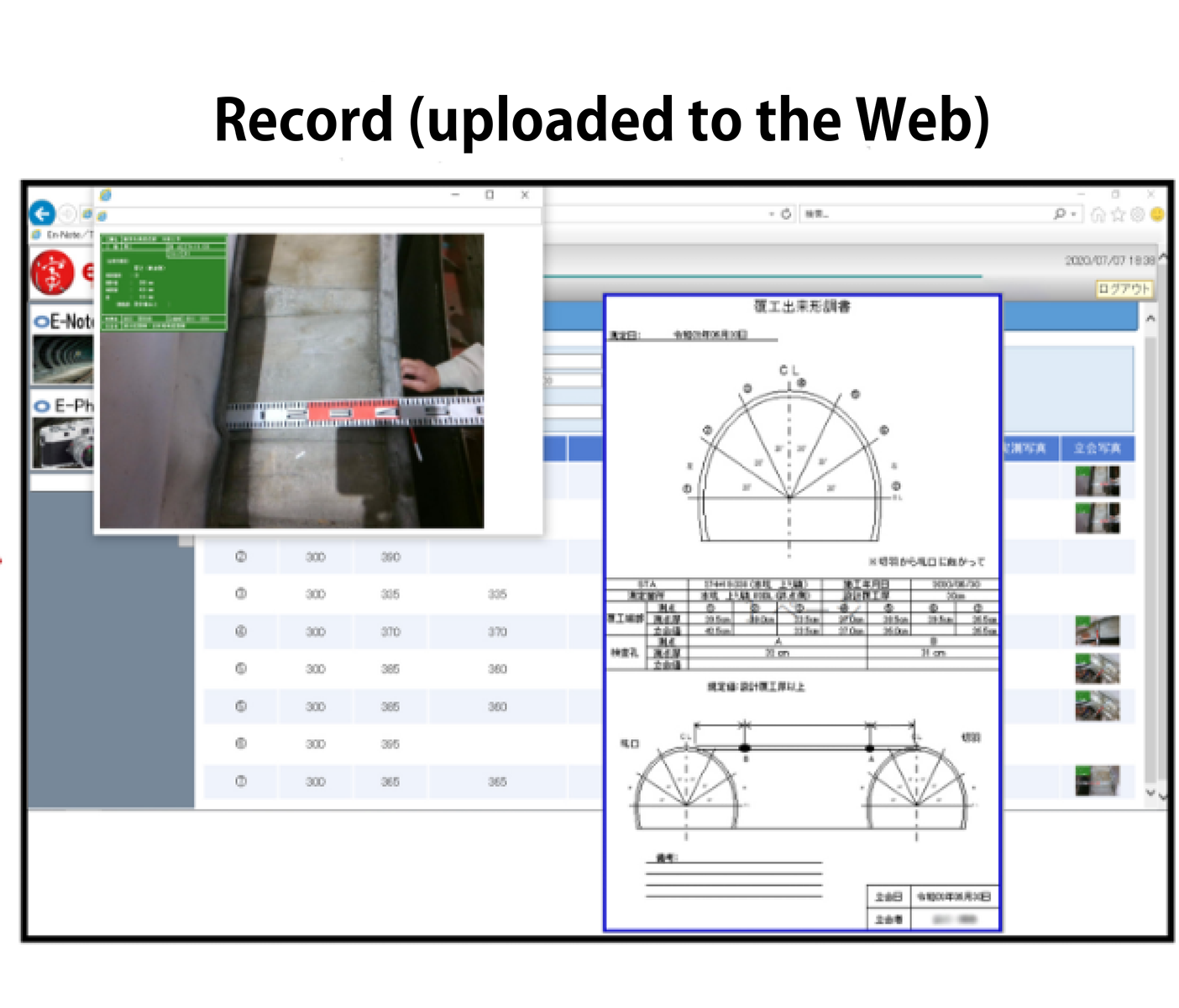

"Live Remote Witnessing System" Reduces Inspection Time Loss

The live remote witnessing system performs an inspection while sharing the data from images taken by a tablet device onsite between the client and a construction worker, and produces an inspection record on the spot.

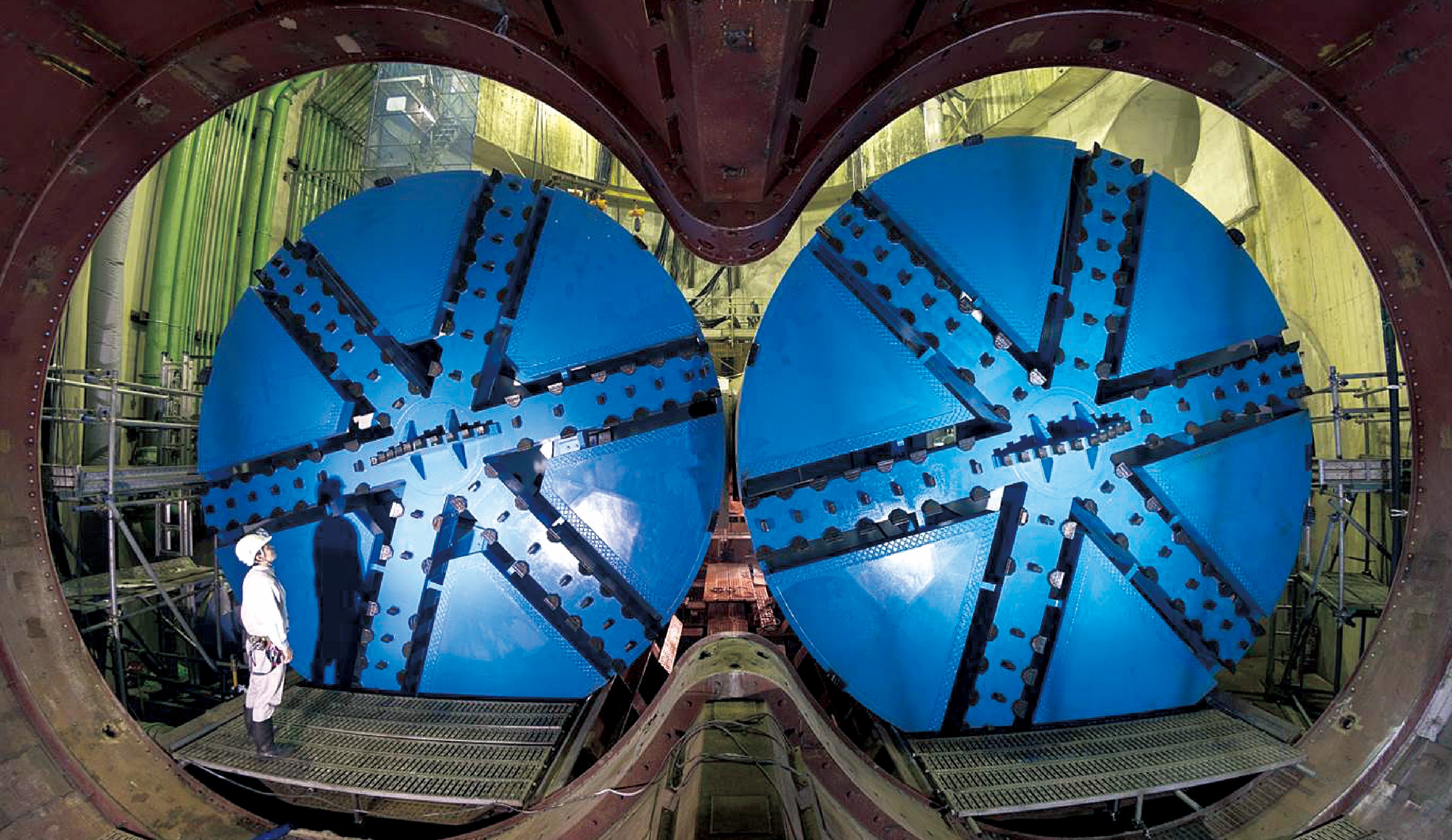

In many cases of mountain tunnel construction, the client's office is far away from the contstruction site, and the client's inspector must spend a great deal of time traveling to the site. Moreover, the inspectors make the rounds to multiple spots in the site in one day, and this has caused lost time for site personnel as they wait for the inspector to make it to their spots.

If this system is introduced, the client can begin scheduled inspections promptly, without traveling to the construction site. Site personnel enter numerical data of inspection spots into the record system, create an electronic blackboard, and take photos. This is confirmed through two-way communication via live video and voice. Once the client approves it, it is uploaded to the cloud to complete the inspection. This also frees the site office from the work of sorting photos and producing documentation. It has the advantage of reducing time loss for both the client and the construction workers, and helps prevent infection by reducing the opportunities for contact.

Company-wide Response to the "New Normal"

Shimizu is maintaining corporate activities while working to reduce the risk of infection, and is therefore rapidly pursuing digitalization of operations and workstyle reforms, such as the distribution of mobile PCs and use of video conferences. More specifically, we have installed video conferencing systems in each meeting room and concentration booths to use for video conferences to accommodate the rapid increase in video conferences.

We have also drastically revised the way we work by promoting paperless operations and PC-based work by creating a workflow for approval documentation and eliminating signatures and seal imprints on internal notices and documentation. We have also established spaces in some company housing and dormitories to use as satellite offices, and are implementing flexible workstyles.

In the future, we will continue to maintain a broad, flexible perspective without getting stuck in rigid concepts, and will implement initiatives aimed at achieving a new normal.

The information posted here is the current information on December 24, 2020.

Please be aware that this information may have changed by the time you view it.