The New Era of Tunnels Next-Generation Tunnel Construction System: Shimizu Smart Tunnel

Since 2018, Shimizu Corporation has been developing a next-generation tunnel construction system, designated as Shimizu Smart Tunnel. This system utilizes the latest technology to markedly enhance productivity and safety in mountain tunneling and shield tunneling projects. We are working toward practical application through a series of demonstration tests of the various fundamental technologies that comprise the system.

Technologies to improve productivity and safety at the construction site

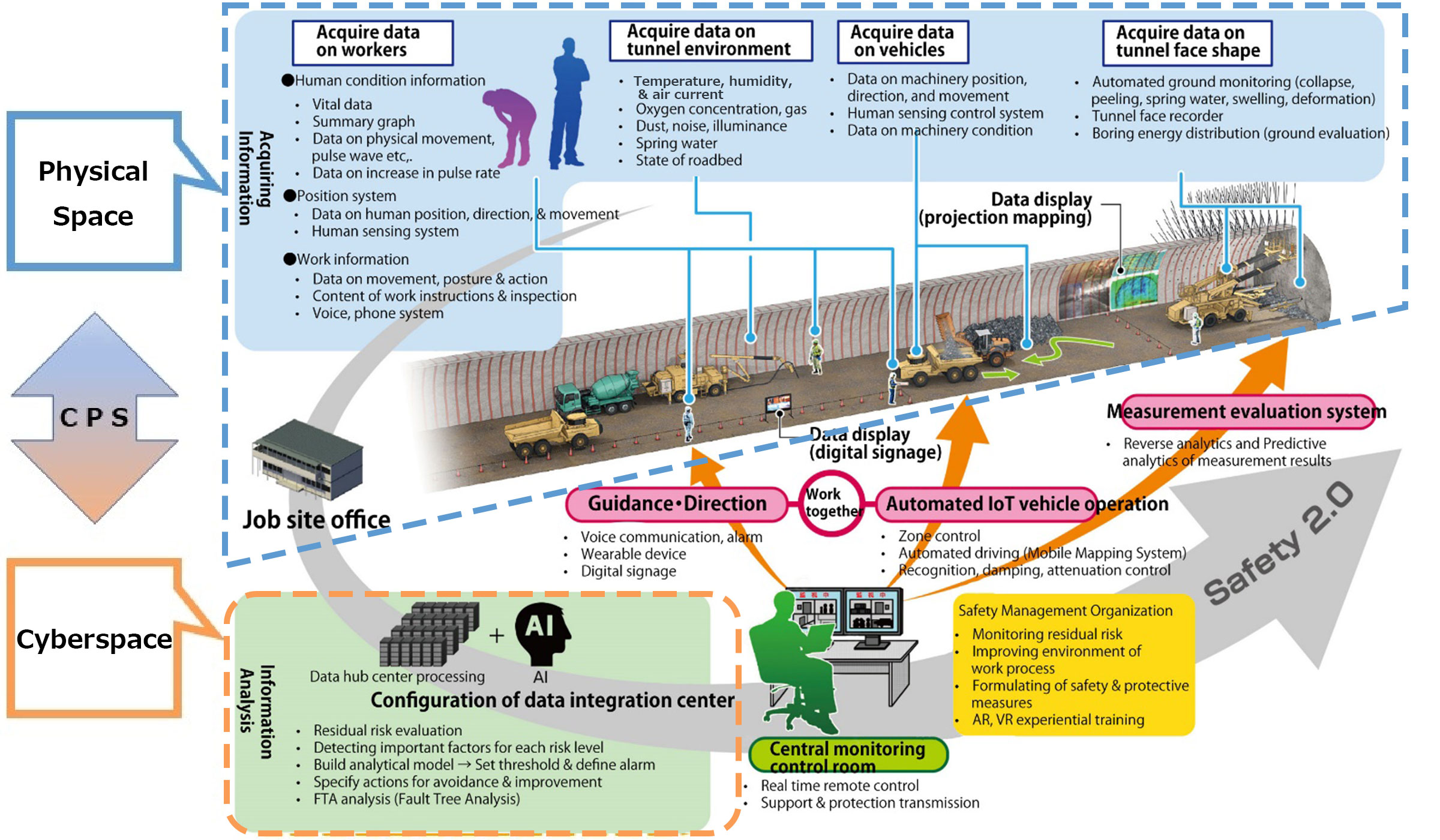

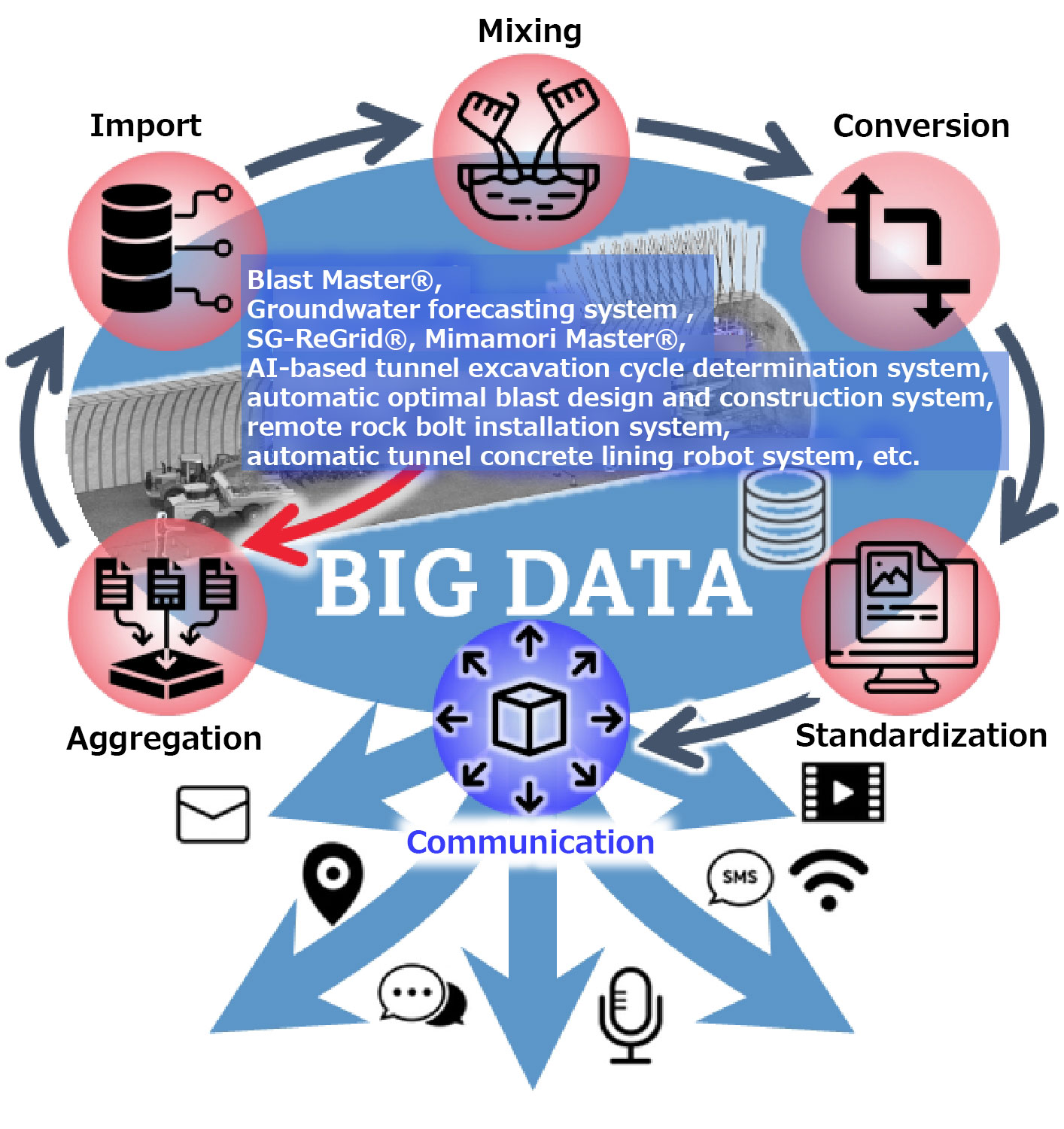

Shimizu Smart Tunnel is a next-generation tunnel construction system that

utilizes ICT, IoT, and AI technologies. It collects all kinds of information in physical space (the construction

site), including tunnel face conditions, construction data of construction machinery, and the location and

status of workers. Based on the analyses of the information conducted in cyber space then provides feedback to

the tunneling sites, thereby markedly enhancing productivity and safety at the sites.

Systems for mountain

tunnel construction can be grouped into three categories:(1) robotic construction production systems, (2)

advanced mountain construction management systems, and (3) automatic safety support and warning systems, each of

which consists of several fundamental technologies.

See more

See more

See more

See more

See more

See more

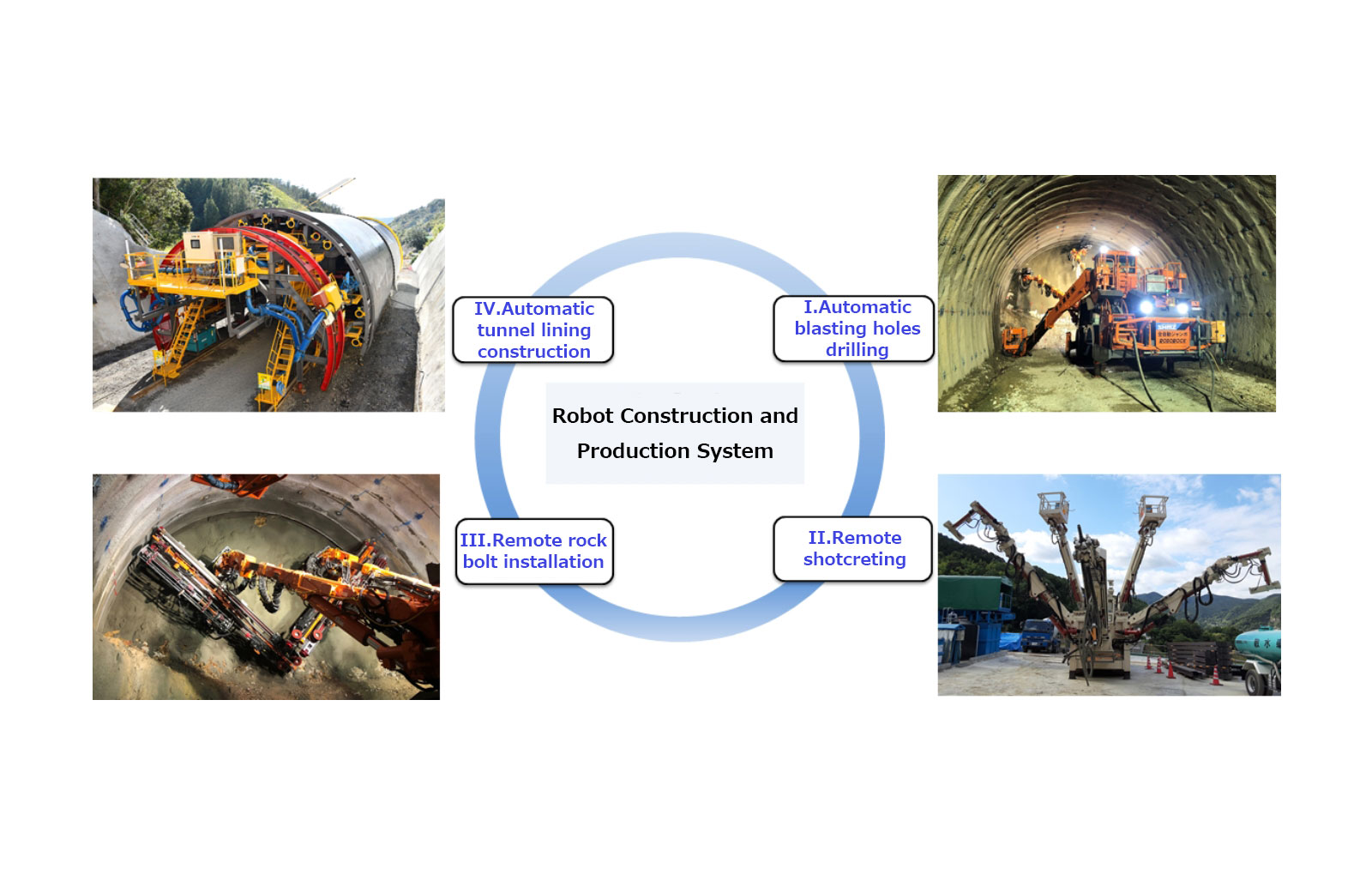

Robot Construction and Production System

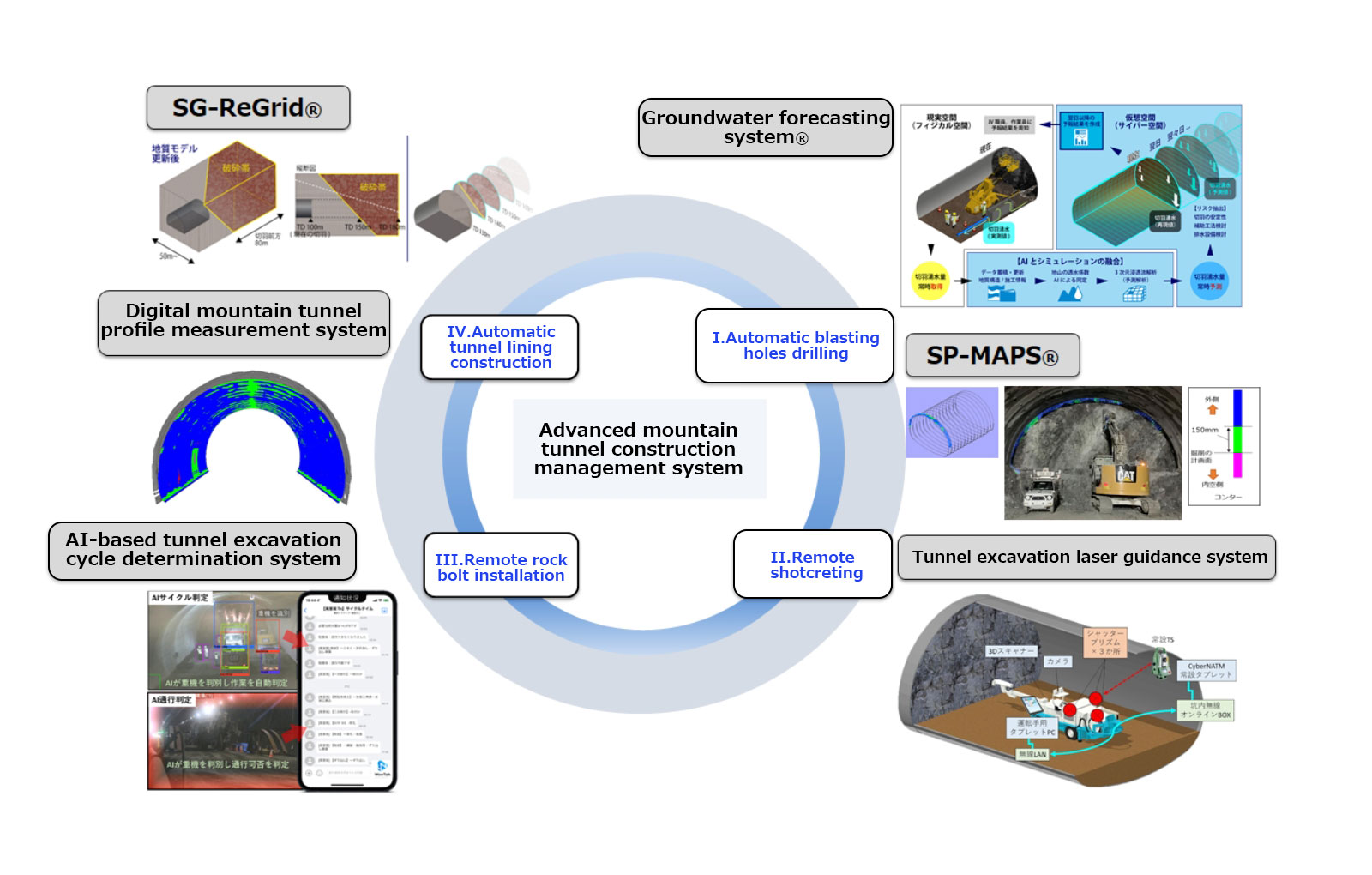

Advanced mountain tunnel construction management system

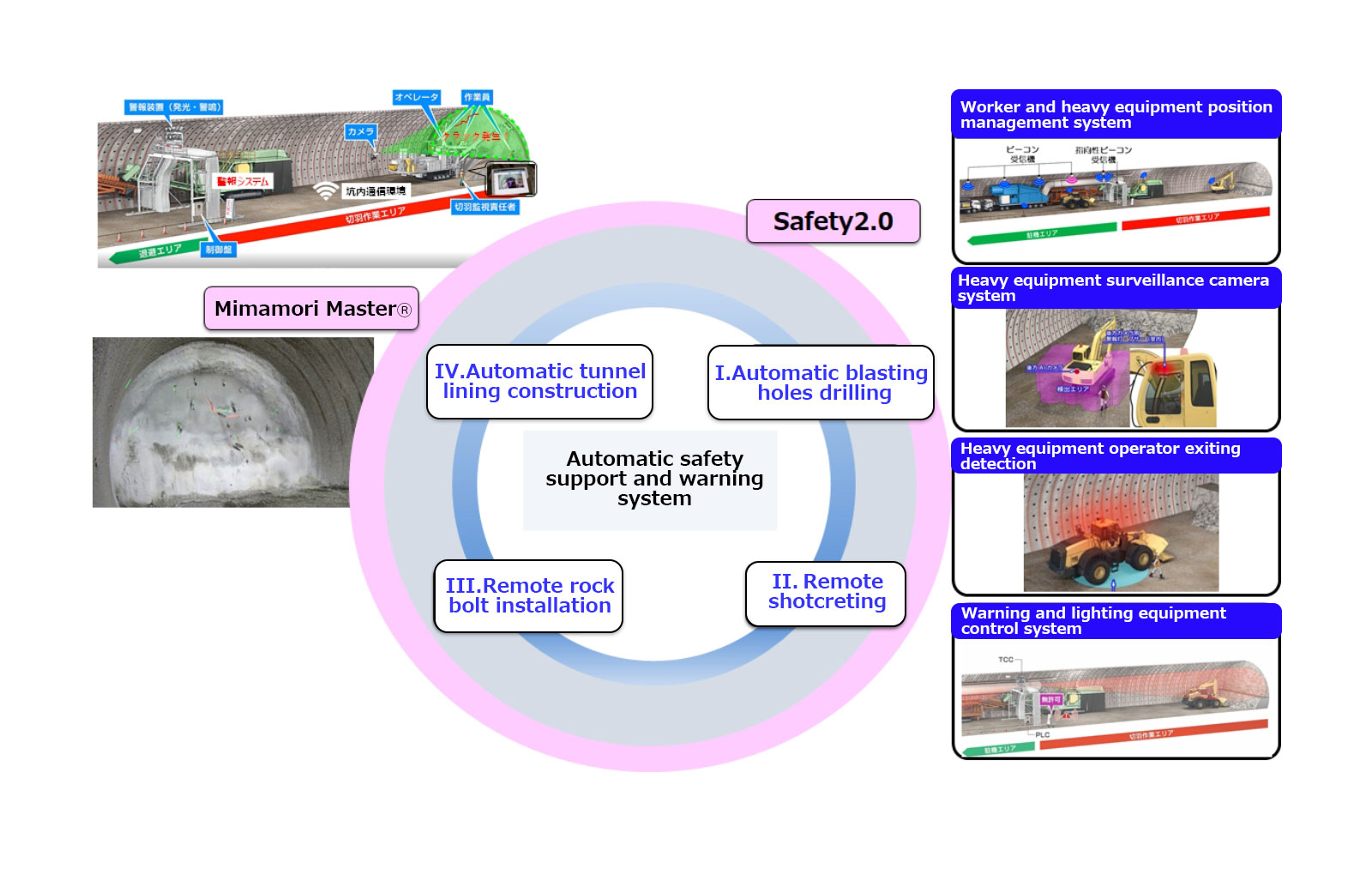

Automatic safety support and warning system

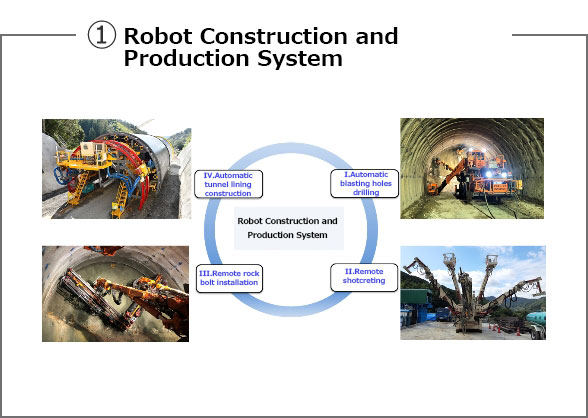

①Fundamental technologies of robotic construction production systems

Drilling process in blasting excavation: Blast Master®, a system that reduces the amount of overbreak

This system significantly reduces the amount of extra excavation

(overbreak) and facilitates the attainment of a uniform and smooth excavation surface, thereby ensuring the

efficacious blasting excavation of mountain tunnels.

The excavation profiles obtained from the

vehicle-mounted 3D scanner can be used to evaluate the overbreak. Based on this, the borehole drilling

position and angle can be automatically adjusted, and the excavator can be automatically updated with the

optimal blasting pattern for the geological condition.

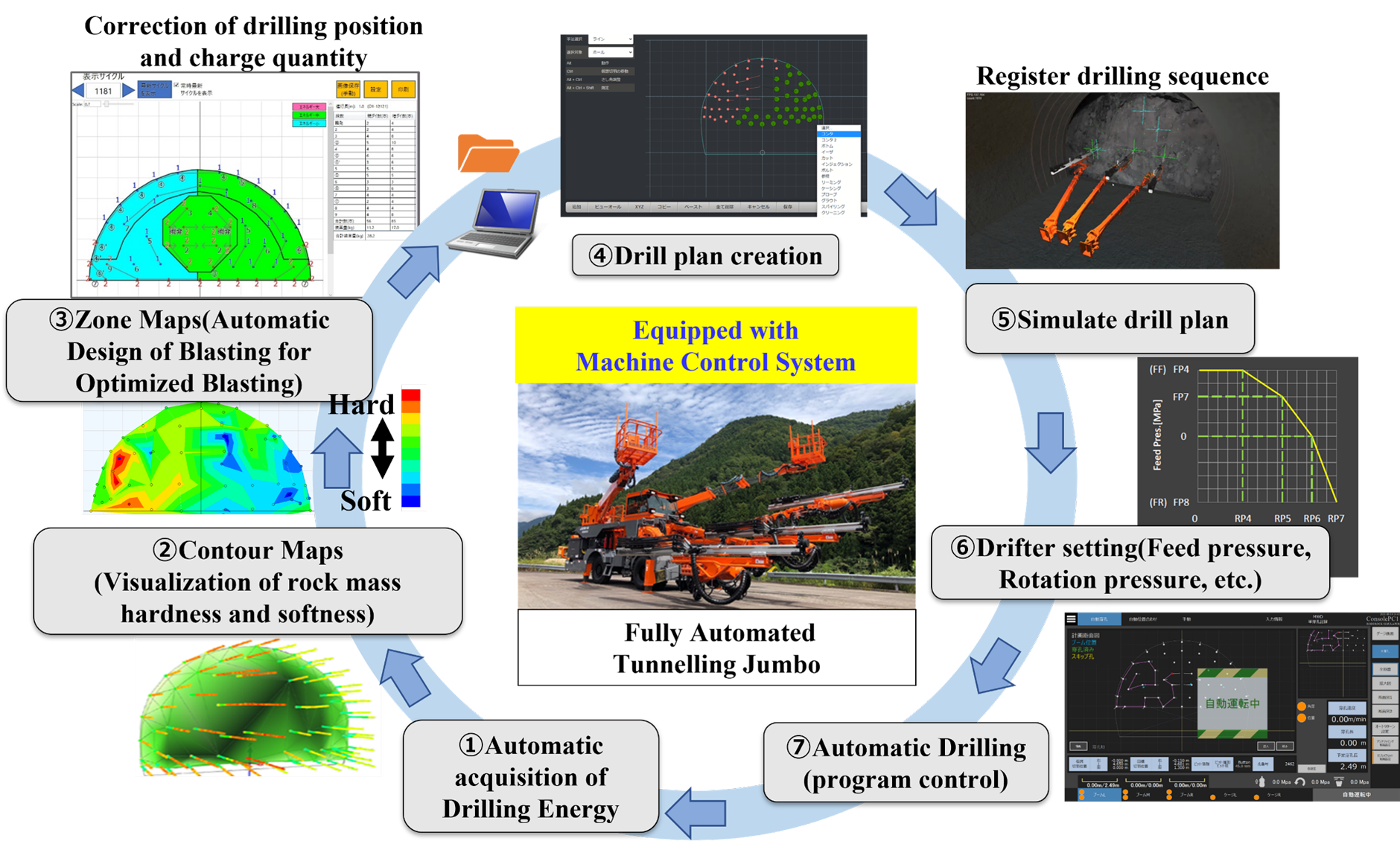

Drilling process in blasting excavation: Automatic optimal blasting design and construction system

This system visualizes the hardness of the geology and derives the optimal blasting pattern based on changes in energy during drilling measured by a fully automatic computer jumbo. In addition, the drilling plan created based on the blasting pattern can be imported into the computer jumbo for programming control, which allows for automatic construction in the optimal sequence without boom interference.

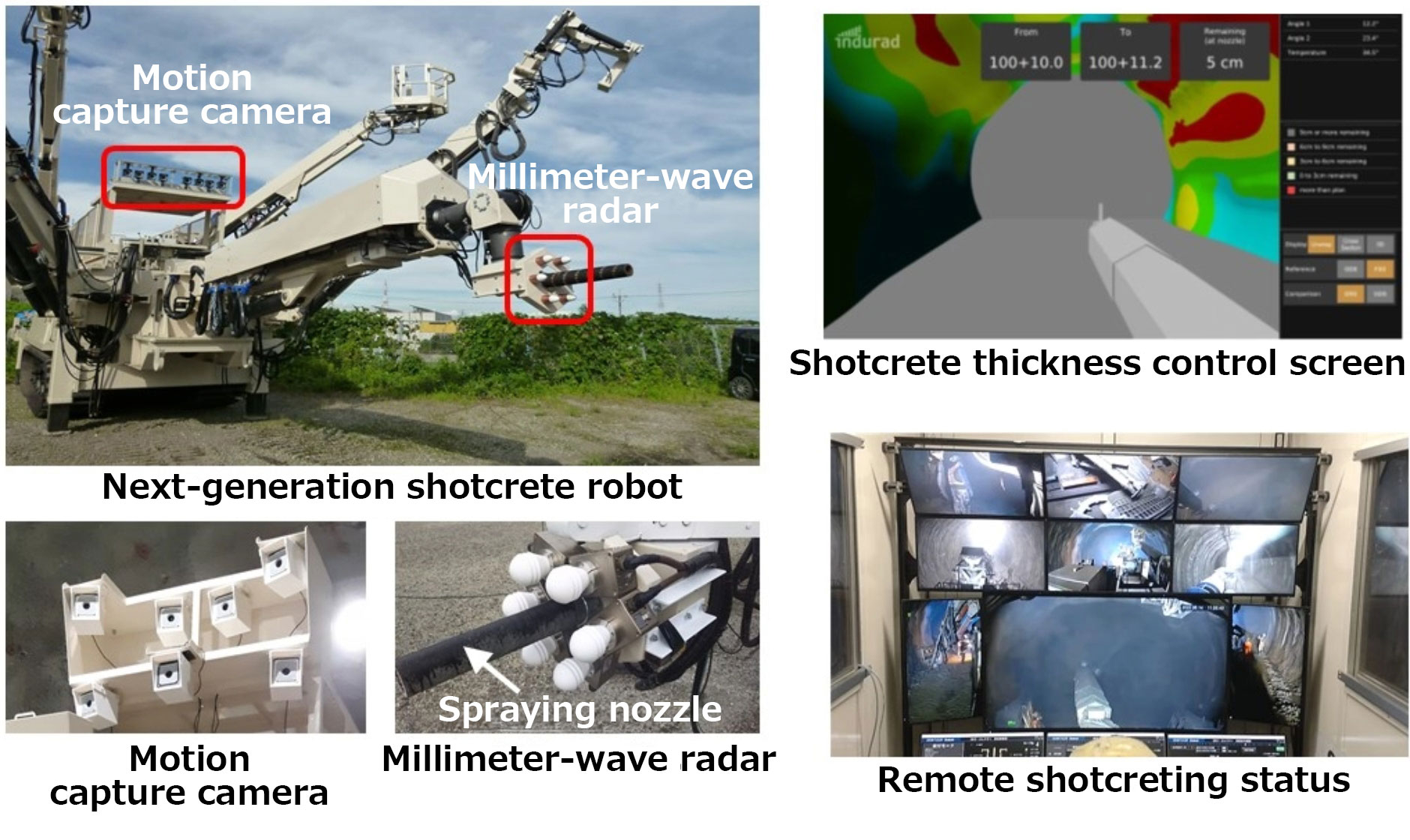

Shotcreting process: Next-generation shotcrete robot

The robot is equipped with a shotcreting navigation system that utilize the fundamental technologies of a motion capture camera and a millimeter-wave radar. The measured values can be integrated to determine and visualize the shotocrete thickness in real-time, thus enabling remote construction.

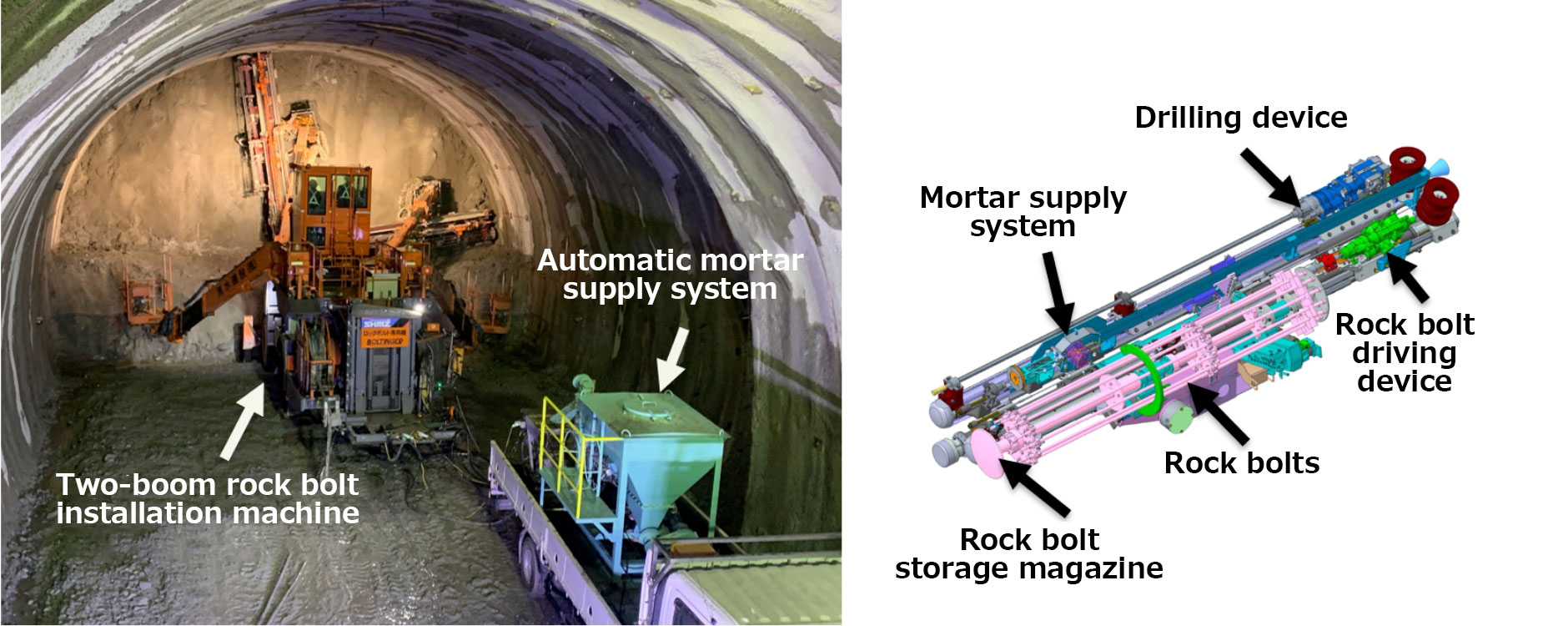

Rock bolt installation process: Remote rock bolt installation system

The remote construction system consists of a two-boom rock bolt driving machine equipped with two bolting units with integrated drilling, mortar filling, and rock bolt driving equipment, as well as an automatic mortar supply system. By mechanizing the work process from rock bolt hole drilling to mortar mixing, filling, and rock bolt insertion, the system reduces manpower by 60% compared to conventional systems. At the same time, it ensures work safety, improves quality, and increases accuracy.

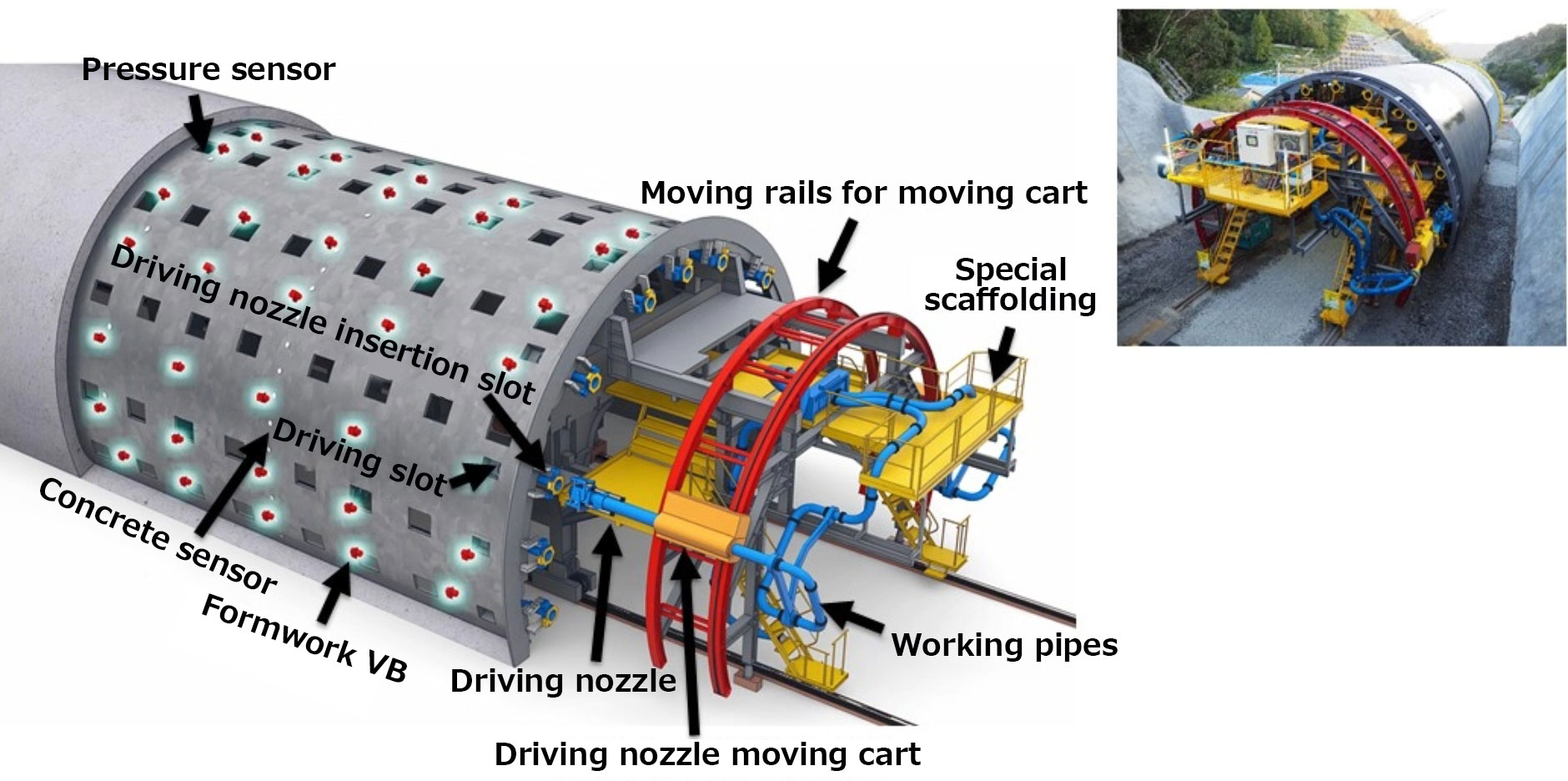

Concrete lining process: Automatic concrete lining robot system for tunnels

The technology automates the progression of a series of operations, from the pouring of concrete to the compaction and tamping of mountain tunnel lining. It consists of a PC system that automatically controls a movable pouring nozzle and formwork vibrator instead of a conventional piping assembly system. By mechanizing tasks that were previously performed manually, it eliminates inconsistencies in construction quality and markedly enhances the quality of the lining and efficiency of the labor process.

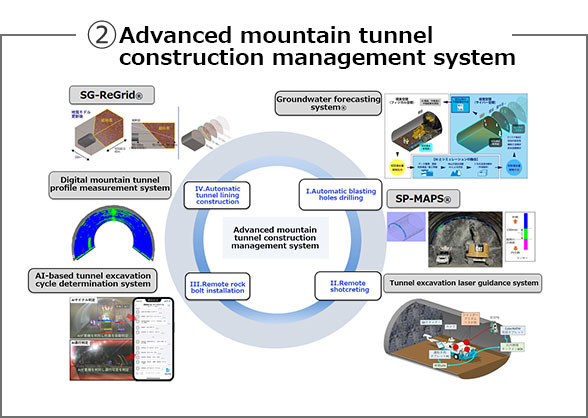

②Fundamental technologies of advanced mountain construction management systems

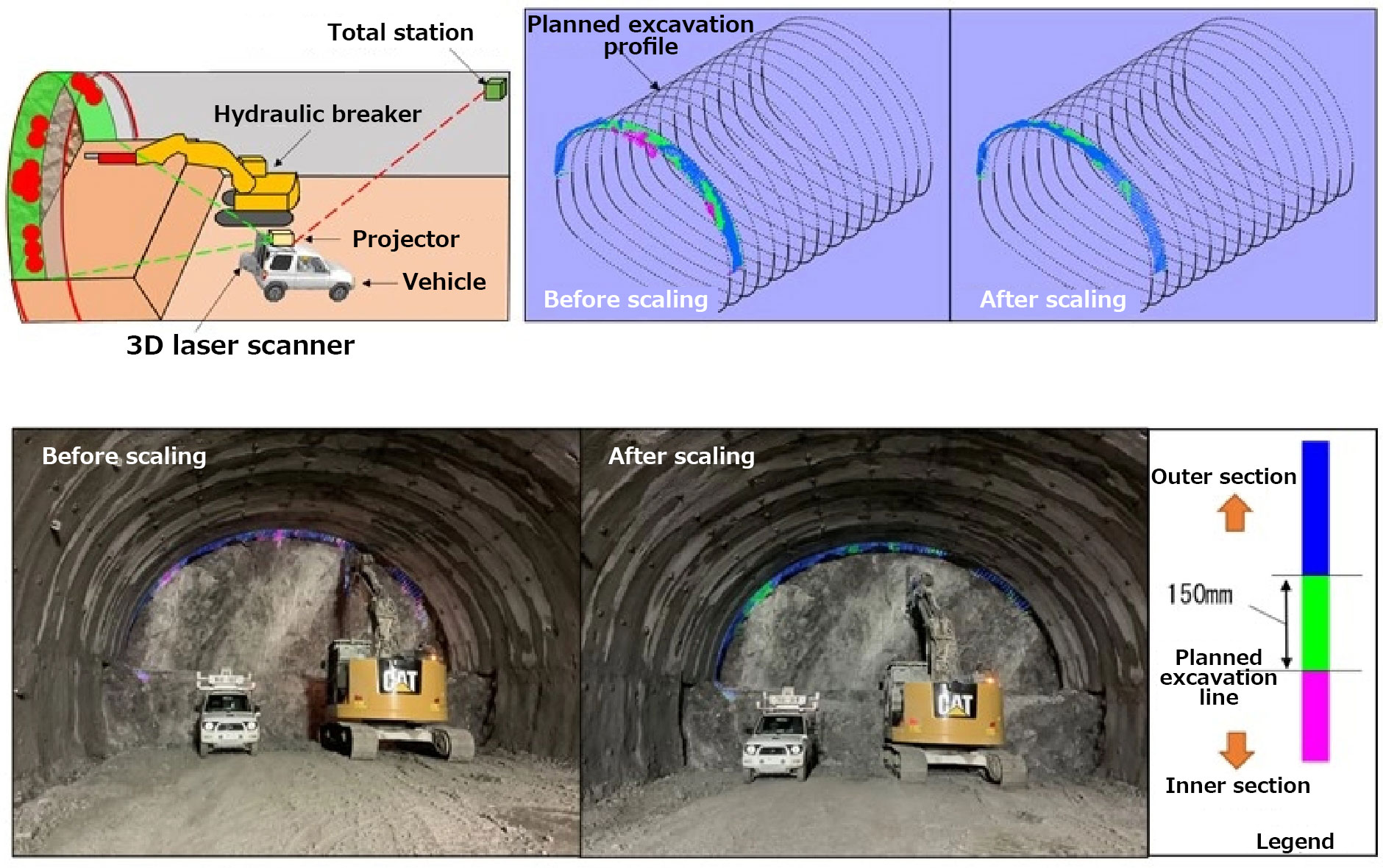

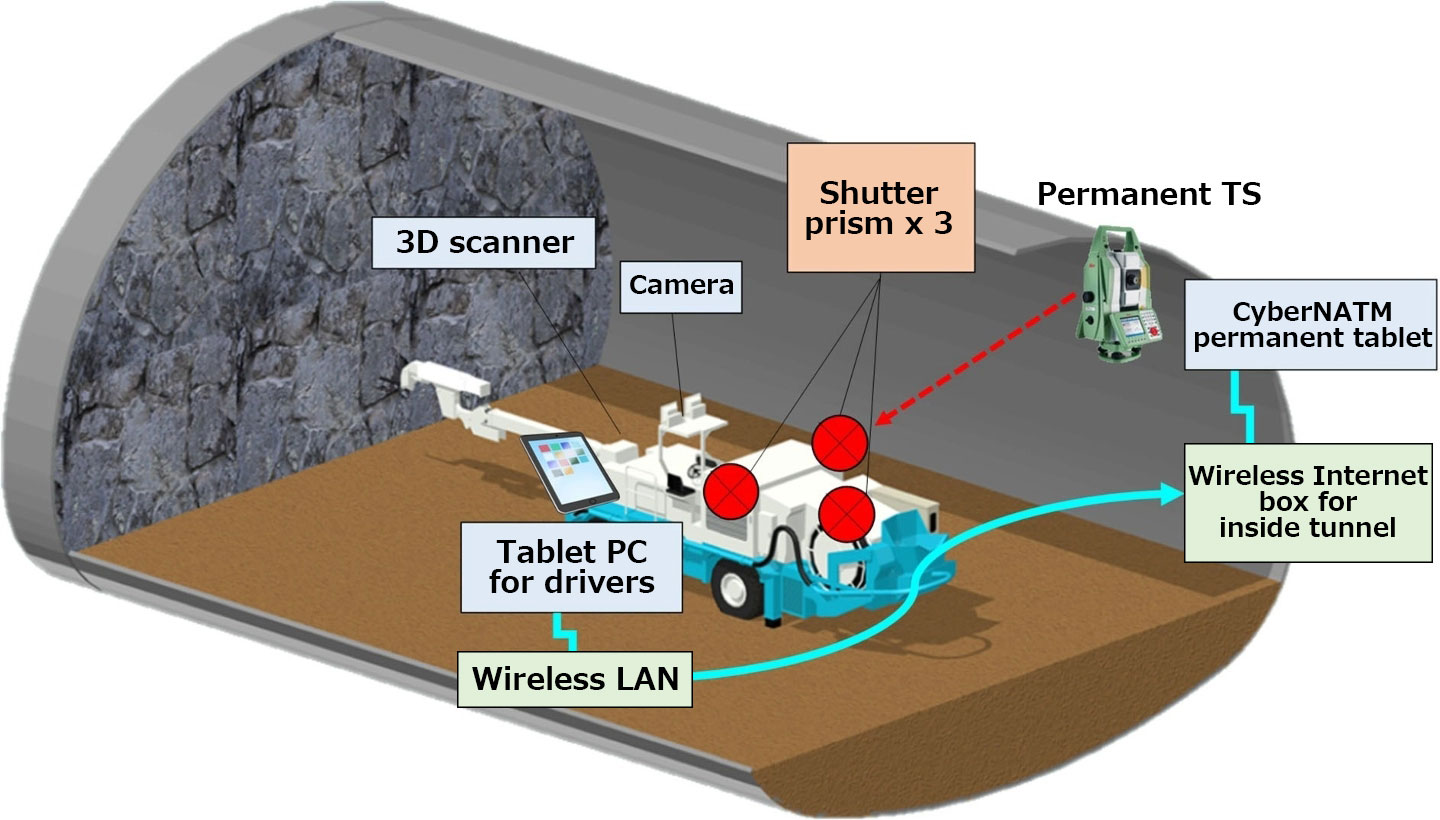

SP-MAPS® Excavation visualization technology

The technology generates color-coded mapping images based on a comparison between the shape of the excavation surface, as measured by a 3D laser scanner, and the design profile. These images indicate the extent of over- or under-excavation and are projected directly onto the excavation surface. This eliminates the need for workers to enter the face, thereby markedly enhancing work safety and significantly increasing work efficiency and accuracy.

Shimizu Tunnel Excavation Laser Guidance System「Shimizu Tunnel Excavation Laser guidance System」

A remote construction management system that measures the shape of the concrete shotcreting surface and evaluates the properties of the face via a 3D scanner and a wide-angle, high-precision camera mounted on the shotcrete machine. By utilizing the shotcrete machine as a measuring device, the need for visual observation work just below the tunnel face can be eliminated. In addition, measurement data and photographed images can be automatically used to create reports on the quality and thickness of the shotocrete, analyze images of the tunnel face, and determine its properties using AI. This provides significant labor savings in construction management operations.

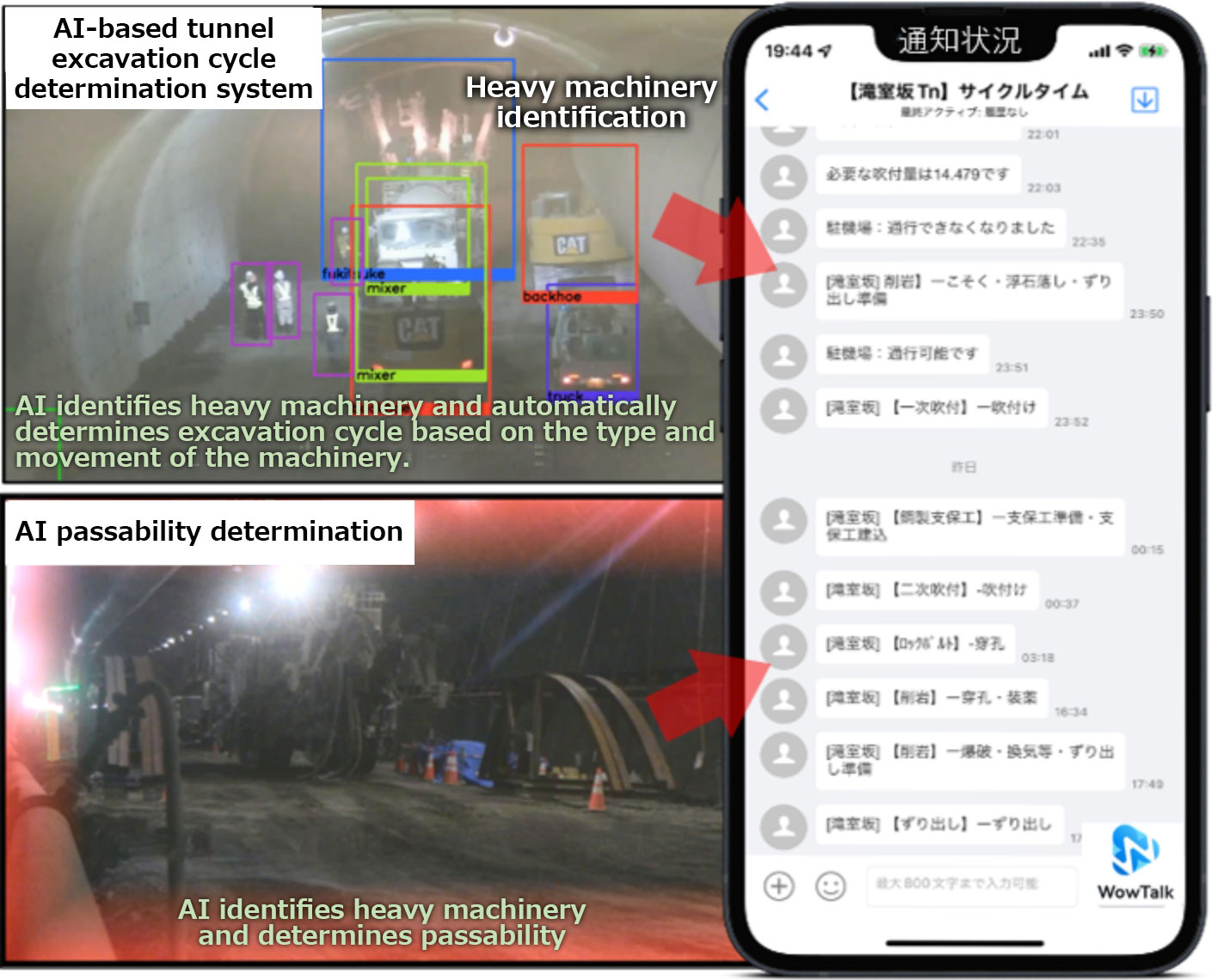

Technology for improving construction efficiency through AI

In the system, AI automatically determines the work status and whether or not the tunnel is passable based on images from webcams installed at a distance of 40 meters behind the tunnel face and in close proximity to the parking area for heavy equipment. The results are provided to relevant personnel in real-time. In the past, it was difficult to grasp the work being conducted near the tunnel face from outside. Furthermore, even when the tunnel was impassable due to the construction work, there was a delay in communicating this information, resulting in prolonged waiting time for workers and heavy equipment. The system can provide real-time notifications on the status of the construction site, enabling efficient workflows and reducing waiting time.

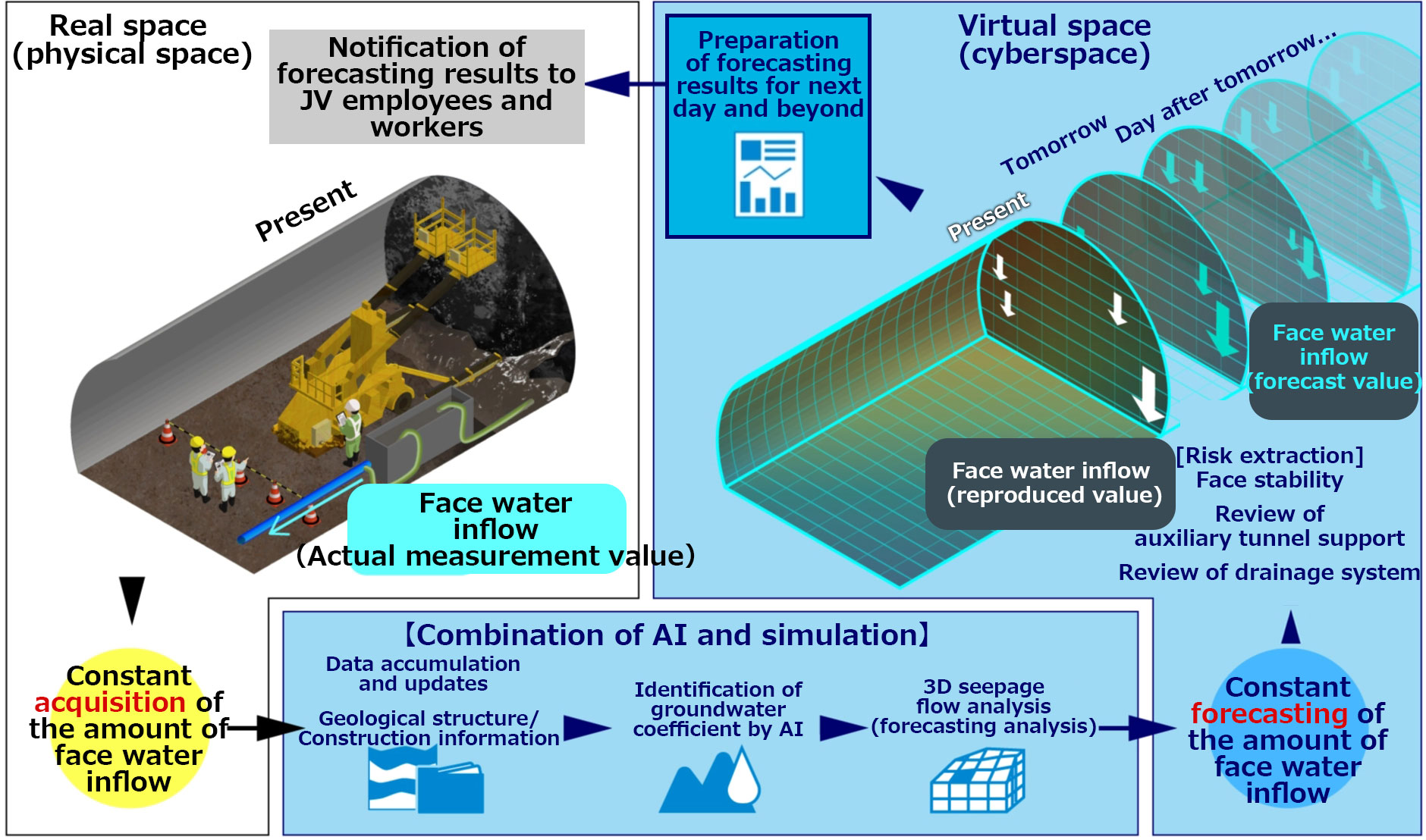

Groundwater Forecasting System

The system employs a virtual space that accumulates and reflects construction data acquired on daily basis on site to simulate the temporal changes in the groundwater environment of a face. Based on the results of these simulations, the system provides timely notification of risk information related to ground water to relevant personnel involved in construction. The system also automates the entire process, from the acquisition of field measurement data to the final dissemination of risk information to workers, significantly reduces the workload of site managers. In addition, it can mitigate risks by constantly implementing future projections while constructing.

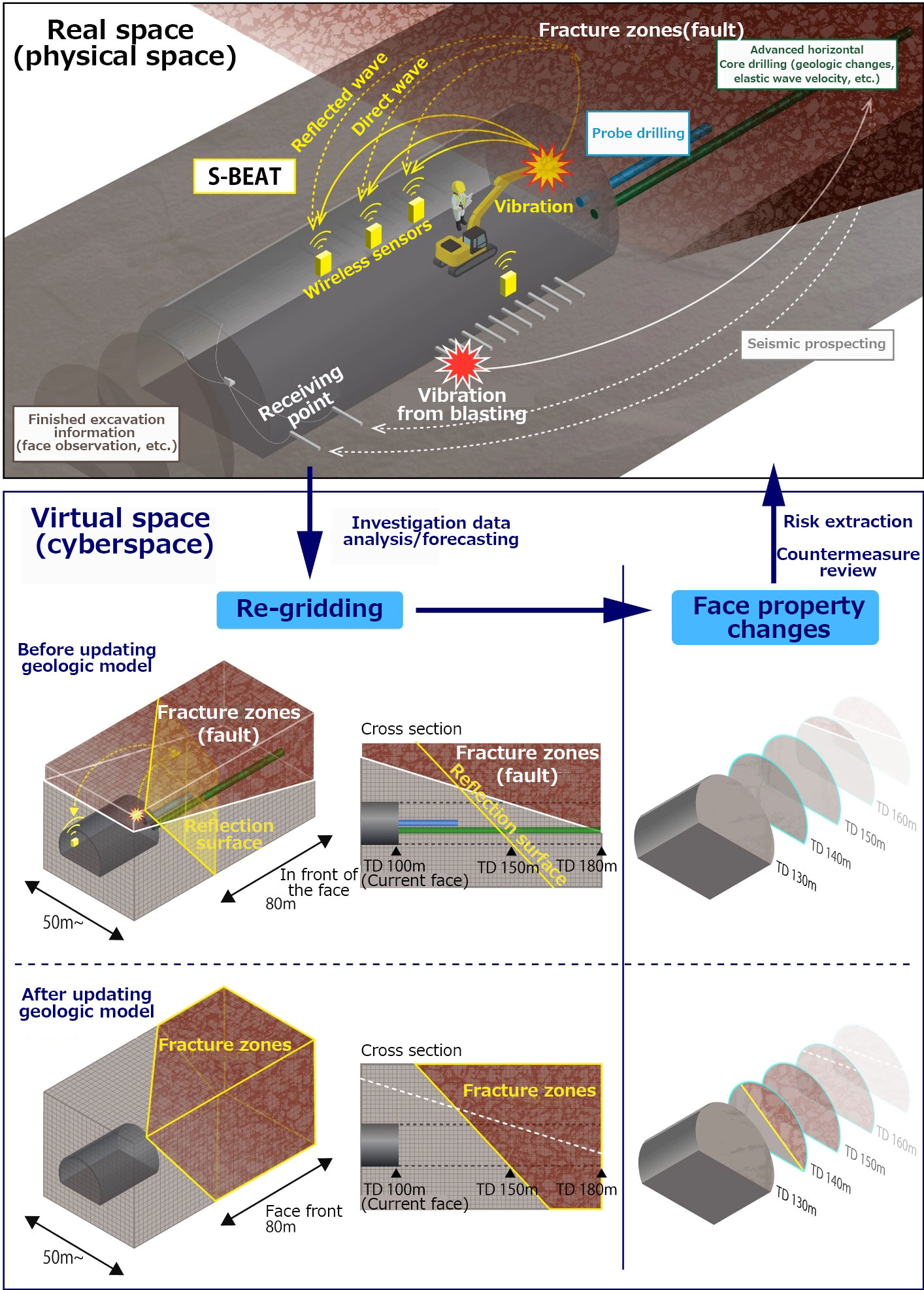

SG-ReGrid® sequential updating system for 3D geological models

The system can automatically and quickly update the 3D geological model utilized for construction review to the latest model, reflecting the forward exploration data acquired during construction. The geological distribution predicted in front of the face can be visualized sequentially and directly reflected in the numerical analysis model, allowing timely consideration of countermeasure work.

Cloud management platform for construction management information

A data platform that facilitates centralized management of various data obtained from virtual space (cyberspace) and real space (physical space) utilizing cloud computing services. The data collected and accumulated utilizing this technology is sequentially updated and fed back to the next stage of construction to form a mechanism for generating useful information. The promotion of construction DX will facilitate improvements in productivity, promote reform of work styles, and ensure the availability of a skilled workforce for the future.

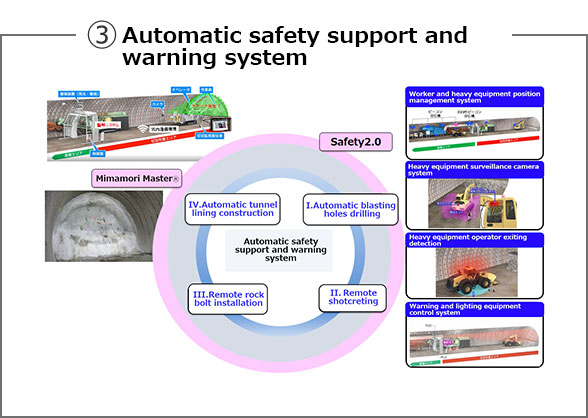

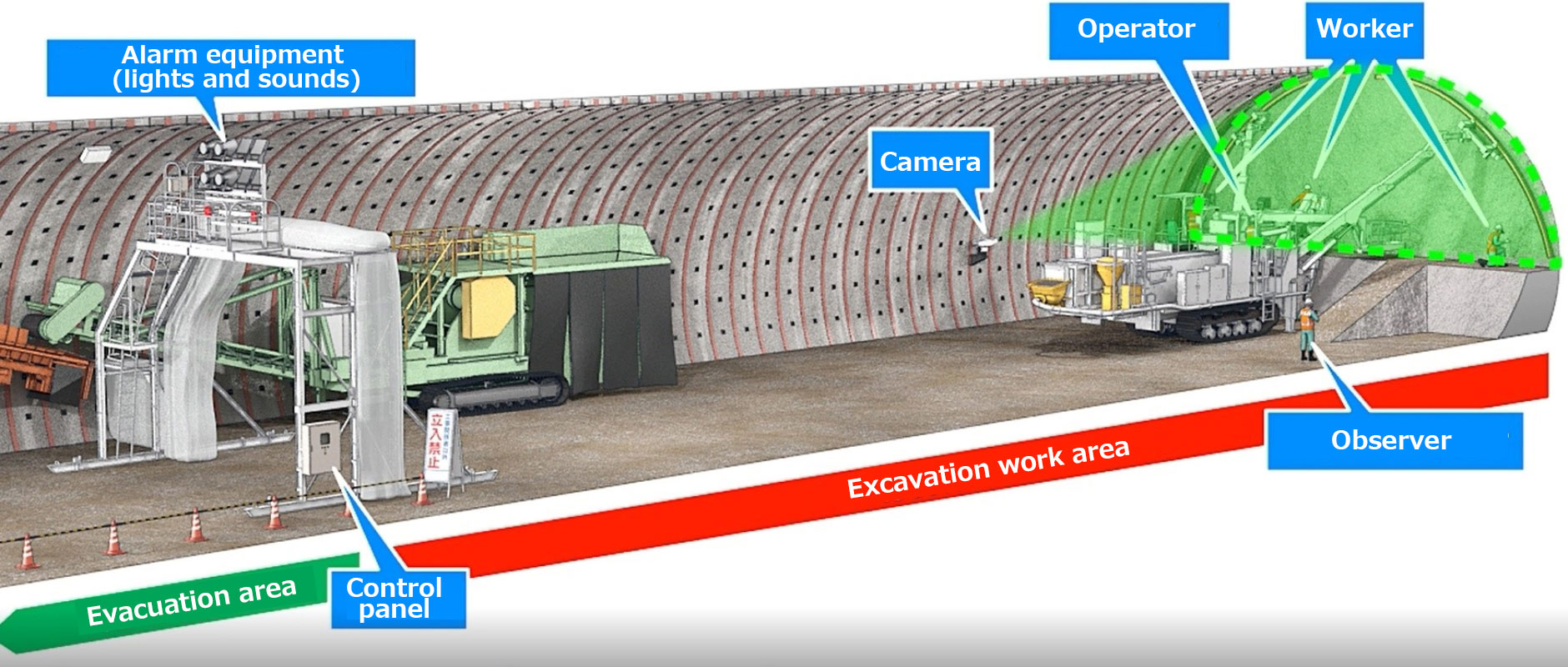

③Fundamental technologies of automatic safety support and warning systems

Mimamori Master®

This face monitoring support system utilize deep learning algorithms (AI) to detect cracks on shotcrete, one of the forewarnings of face collapse, in real-time and trigger an alarm. When work is required nearby tunnel face, the system is able to detect cracks in real time, thereby reducing the risk of loose rockfall disasters.

Expanding foundations supporting social infrastructure

The digitalization of construction management, achieved through the integration of diverse ICT, IoT, and AI technologies, promises not only enhanced productivity and safety but also a more favorable working environment. By saving manpower and labor and reducing the workload of workers, this approach can positively impact the overall efficiency and sustainability of tunnel construction. Shimizu Smart Tunnel, in particular, is poised to become a mainstream technology in this field, contributing to the advancement of social infrastructure.

The information posted here is the current information on March 15, 2024.

Please be aware that

this information may have changed by the time you view it.