September 22, 2022

Shimizu Corporation (President: Kazuyuki Inoue) adopted BILMUS, a vibration control system it developed to provide an exceptional vibration control effect for earthquakes of varying intensities and simultaneously resolve the opposing issues of resilience and economical design of tall buildings, in the South Tower of the Shibaura Project as the first implementation. The distinctive characteristics of this system are that the building itself functions as a vibration control system and that it can be implemented regardless of the structure or use of the building.

Vibration control structures began spreading in use in Japan following the Great Hanshin-Awaji Earthquake in 1995. Over the past quarter of a century, various vibration control systems have been developed, but tall buildings still require multiple systems to control vibration. Furthermore, when building usability is taken into account, the only space where the device can be installed is in the flames around the core of the building, so this limits the vibration control effect. BILMUS turns this thinking on its head to revolutionize the structure of tall buildings.

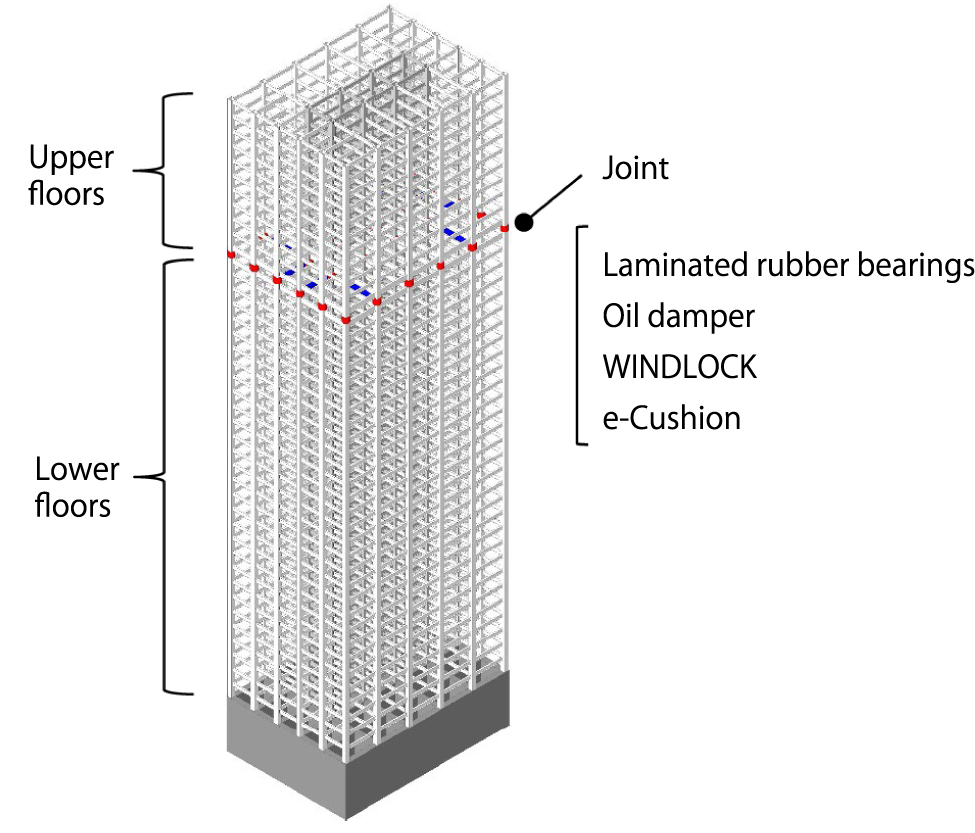

The distinctive feature of the BILMUS is that the upper and lower floors of the building are structurally independent and connected by laminated rubber bearings and oil dampers used in seismic isolation. During an earthquake, the upper and lower floors oscillate in the opposite direction to cancel out the vibration, turning the building itself into a vibration control system. The upper and lower floors are connected where the upper floors will account for 10-50% of the total weight of the building. Adjusting the frequency of the upper floors with laminated rubber bearings provides an exceptional vibration control effect. As a result, during an earthquake, the shaking (acceleration) of the upper floors is, at its maximum, less than half that of when using conventional damping structures, helping to prevent furniture and appliances from falling over and damage to the building interior and exterior, and dramatically improving the resilience of tall buildings. Moreover, as opposed to conventional vibration control systems, which require the installation of multiple systems, this system offers a greater flexible in design.

In addition to laminated rubber bearings and oil dampers, the joints are equipped with a wind-resistant locking mechanism called “WINDLOCK” and a safety device called “e-Cushion”, which prevents excessive deformation. WINDLOCK activates during seasonal and other strong winds, preventing deformation of the laminated rubber bearings or, in other words, the horizontal deformation of the joint. While maintaining operations of elevators that pass through the joint, the locks can be instantly released in the event of an earthquake, even during strong winds, to allow the joint to function. Meanwhile, e-Cushion plays the role of ensuring the safety of the building structure during major earthquakes. The cost of installing the joint can be offset as the vibration control effect reduces the number of the building’s structural components and vibration control dampers.

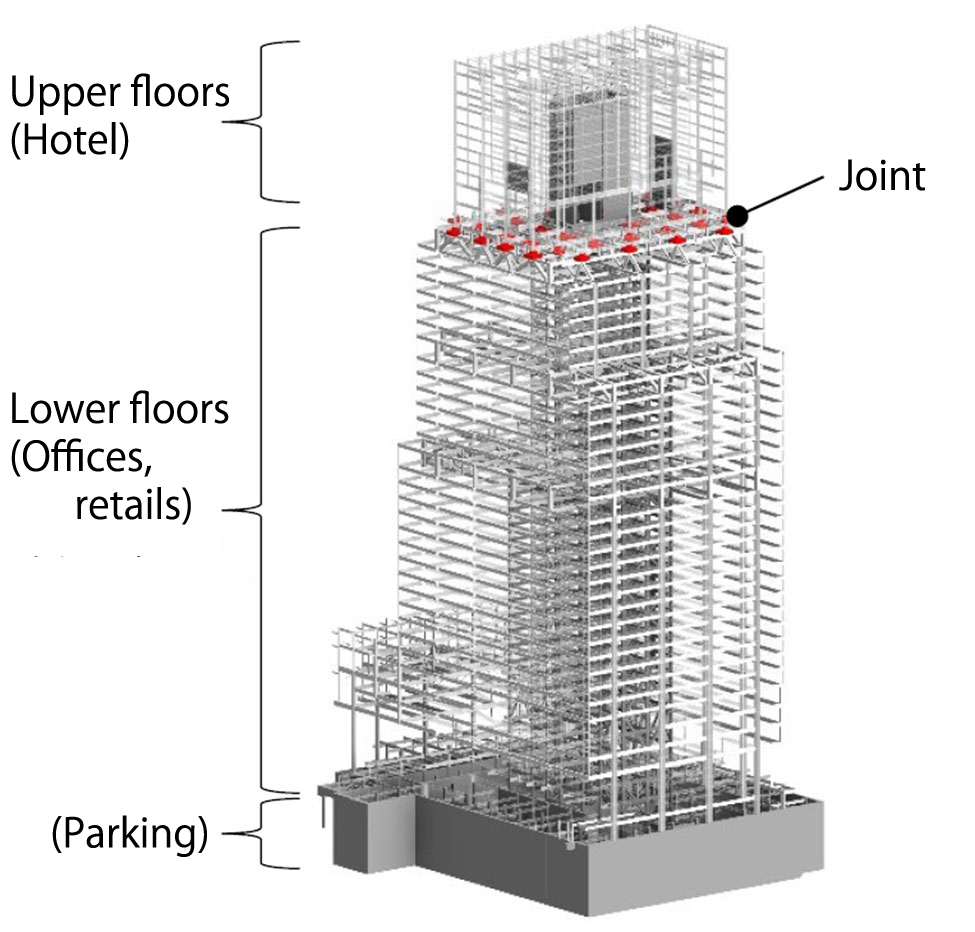

The Shibaura Project Is a large-scale complex development project commissioned by Nomura Real Estate Development Co., Ltd. and the East Japan Railway Company. Shimizu contracted the South Tower, which is under construction. It is a 235-meter building with 43 floors above-ground. The first to 34th floors feature a steel structure and are used for offices and retails. The 35th floors and above feature a steel structure (reinforced concrete used in the core walls) and are used as a hotel. The business operators were impressed by the advantages offered by BILMUS in terms of structure and design, which led to its adoption.

Under the plan, a joint will be installed where the use of the building switches from offices to hotel space 170 meters above ground. In this joint, 38 laminated rubber bearings, 62 oil dampers, 12 WINDLOCK units, and eight e-Cushions will be installed. The hotel portion on the upper floors will weigh around 34,200 tons, accounting for roughly 15% of the total weight of the building. Compared to the original plan, which was designed based on conventional vibration control structures, the office portion on the lower floors has a superior vibration control effect, more than 200 fewer vibration control devices will be installed, 1,500 tons less of steel frame will be used, and the panoramic view and effective area will be expanded. Livability befitting of a luxury class hotel will be ensured in the hotel portion on the upper floors even in the event of an earthquake or strong winds.

Going forward, by incorporating BILMUS into our design and construction proposals for tall buildings, we will increase our competitiveness and be able to provide highly resilient tall buildings economically.

≪For Reference≫

Conceptual Diagram of BILMUS

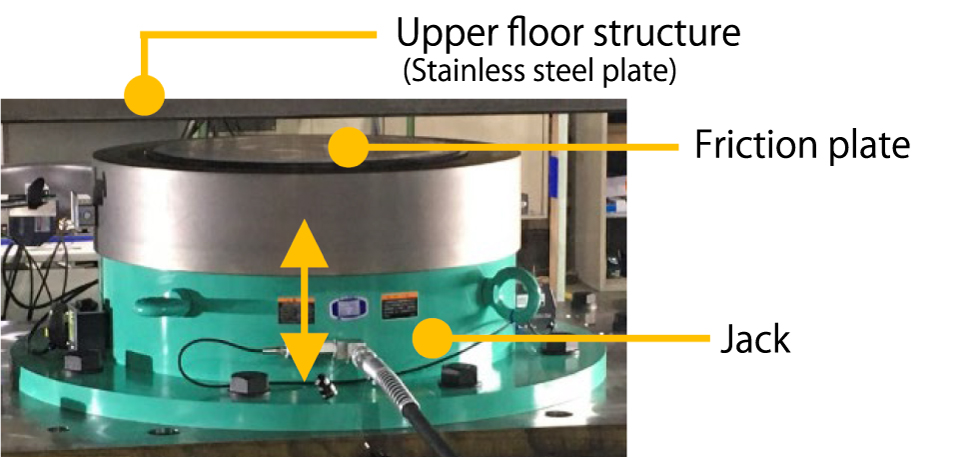

WINDLOCK

During seasonal and other strong winds, a hydraulic jack raises a friction plate (70 cm in diameter) and presses it against a stainless-steel plate that is integrated with the structure of the upper floors, thereby preventing horizontal deformation of the joint using friction. An anemometer installed on the top floor measures wind speed, and a seismometer installed on the ground floor measures seismic force to control the jack.

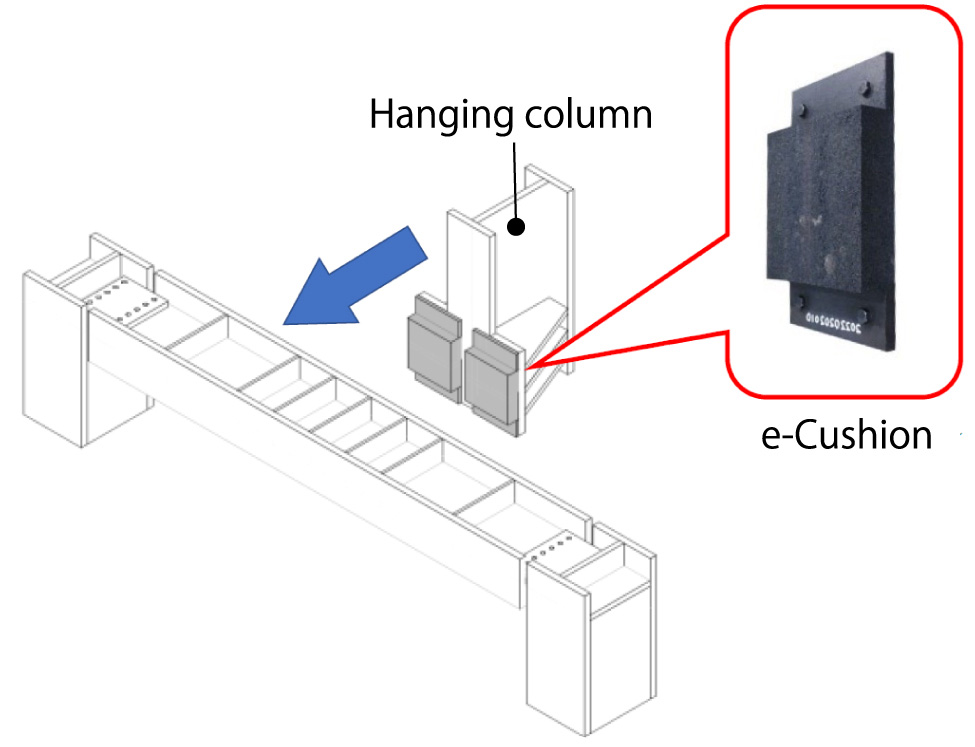

e-Cushion

An e-Cushion is installed on a hanging column (H-column) from the upper floor. In the event that a large earthquake is about to cause horizontal deformation of the joint beyond a certain level, the e-Cushion collides with the steel beams installed on the floor of the joint and serves to keep the deformation from going beyond that level. The e-Cushion is made by sticking recycled rubber chips in place with an adhesive, and is 30 cm long, 30 cm wide, and 7.5 cm high (excluding the flange).

Shibaura Project

| Commissioning entities | Nomura Real Estate Development Co., Ltd. and the East Japan Railway Company |

|---|---|

| Contractors | South Tower: Shimizu Corporation / North Tower: TBD |

| Designers | Maki and Associates, Shimizu Corporation, Ove Arup & Partners Japan Limited, and Nikken Sekkei |

| Address | 1-1-1 Shibaura, Minato-ku, Tokyo (and other building numbers) |

| Site area | Approx. 47,000m2 |

| Total floor area | Approx. 550,000m2 |

| Purpose | Office, retail, hotel, residence, parking |

| Number of floors/height | South Tower 43 floors above ground, 3 floors below ground /approx. 235m North Tower 45 floors above ground 3 floors below ground /approx. 235 m |

| Scheduled start/completion | South Tower Start: October 2021 Completion: February 2025 North Tower Start: FY2027 Completion: FY2030 |

Perspective drawing of Shibaura Project upon completion and structure of South Tower

Tall building on left is South Tower, and building on right is North Tower (not yet started)

The information contained in this news release is the current information on the date of publication. Please be aware that this information may have changed by the time you view it. Please contact the company to inquire for further details.