November 24, 2020

Shimizu Corporation(President: Kazuyuki Inoue)jointly developed the Kakumaru Culvert, with Chiba Ceramic Industry Inc., a component manufacturer. It is a new shape for a box culvert made of precast concrete(PCa)that will contribute to reducing costs as one part of advancing the use of PCa in cut and cover tunnel construction. This box culvert is characterized by the rounded the corners of the box, which reduce the internal force and reduce the amount of reinforced concrete needed. Shimizu explored the shape and rebar arrangement during development, while Chiba Ceramic Industry Inc. handled the manufacturing.

The Ministry of Land, Infrastructure, Transport and Tourism is pursuing i-Construction in a bid to improve productivity at construction sites. One of the key measures in that effort is transitioning to PCa in civil engineering structures but reducing the cost has been a challenge. The development of the new shape of PCa box culvert meets such needs.

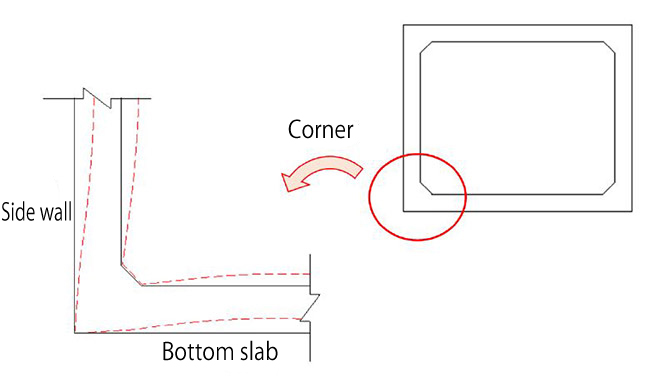

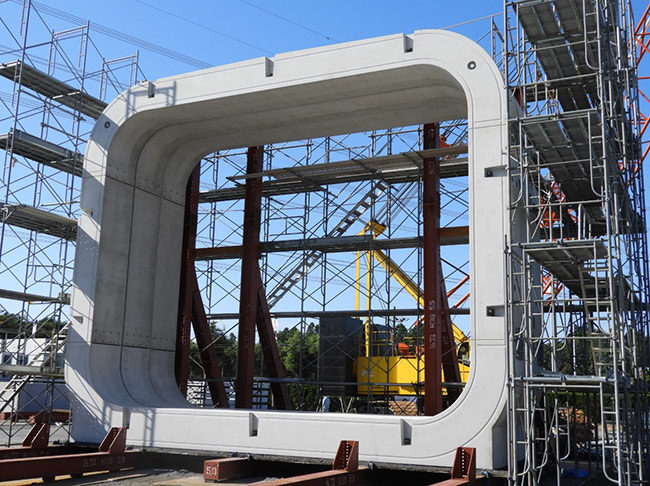

The box culvert is a box-shaped structure for building cut and cover tunnels with a rectangular shaped cross-section. The pressure from earth on some spots causes the L-shaped 90 degree corner angles of existing box culverts to bend into a V-shape, as shown in the diagram. Rounding the corners distributes the load and can therefore reduce the load that acted on some parts by 30%. The rounding of the internal corners and the external corners changes the location of the center and this makes it possible to set the thickness of the side wall, top slab, and bottom slab at will. This resulted in a 40% maximum reduction rebar and a 10% reduction in the amount of concrete compared to conventional PCa components. It has therefore made it possible to reduce the manufacturing cost by about 15% and to manufacture an economically superior product. We conducted the performance test using a test prototype that was half the size of an actual box culvert and confirmed that the Kakumaru Culvert demonstrates performance equivalent to conventional box culverts.

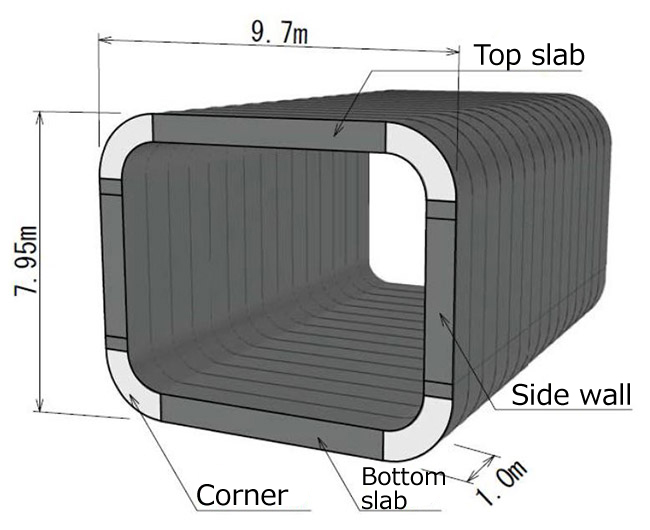

We will use the Kakumaru Culvert next fall in the cut and cover tunnel for construction of the Kawanishi section of the Shin-Tomei Expressway by the Shimizu joint venture. The tunnel will be 98 m long and will use 98 of the Kakumaru Culverts, each of which is 7.95 m high, 9.7 m wide, 1 m thick, and weighs 54 tons. The plant will produce four PCa components at a time, taking into consideration the maximum load of the largest transport trailers. The four components will be joined at site with rebar coupler and mortar. After they are joined into one unit, they will be installed at the designated location and connected to other units to extend the tunnel.

Shimizu will continue to develop technology to control the rising cost of using PCa components in civil engineering structures and believes that promoting the use of PCa will further improve construction site productivity.

≪Reference≫

Kawanishi section of the Shin-Tomei Expressway construction project

| Location | From Mukohara, Yamakitamachi, Ashigarakami-gun, Kanagawa to Ikido, Oyama-cho, Sunto-gun, Shizuoka |

|---|---|

| Customer | Central Nippon Expressway Company Ltd. Tokyo Branch |

| Contractor | Special construction joint venture consisting of Shimizu Corporation and Iwata Chizaki Inc. |

| Construction period | July 22, 2016 to April 21, 2022 |

Image of Kakumaru Culvert used in construction of the Kawanishi section of the Shin-Tomei Expressway construction project

Image of corner deformation(from black line: L-shape to red line: V-shape)

Photo of prototype

The information contained in this news release is the current information on the date of publication. Please be aware that this information may have changed by the time you view it. Please contact the company to inquire for further details.