January 8, 2019

Shimizu Corporation (Kazuyuki Inoue,President) will use Shimizu Hy-wood and Slim Fire-Resistant Wood for the first time in construction of a housing complex in the city of Nagoya. Shimizu Hy-wood is a wooden hybrid frame construction method developed for fire resistant construction of medium to large-sized buildings. Slim Fire-Resistant Wood consists of wood and fire resistant materials. This construction method makes it possible to combine a wooden structure with steel beams (S) or reinforced concrete (RC). Shimizu will use an optimal combination of wood materials and reinforced concrete to ensure earthquake resistance, fire resistance, and sound insulation.

This mid-rise housing complex will be used as housing for Shimizu employees. The basement level is a parking facility and the four floors above ground will contain 26 apartment units. The building area is 799 m2 per floor with a total floor area of 3,152 m2. It is scheduled for completion in February 2020. During the design phase Shimizu created the living space in wood and will use a total of 178 m3 of wooden materials for the interior and exterior finishing. Japan’s Ministry of Land, Infrastructure, Transport and Tourism selected this plan as an example of “Sustainable Architecture Promotion (wooden architecture category)” in 2018.

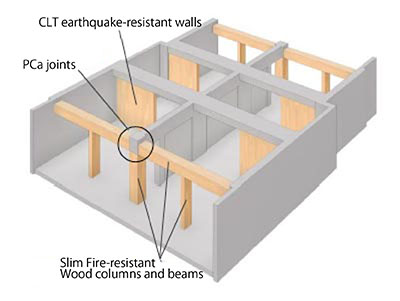

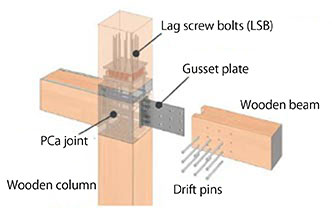

The basic structural plan involves artificial ground that is 50.5 m wide, 17.0 m deep, and 90 cm thick on top of 11 seismic isolation devices installed on the heads of the basement floor columns. The frame for the 4-story building will be built on top of that. The wood portion will consist of 56 beams, 28 columns and 56 studs around the outer circumference of the building and 57 earthquake-resistant walls, with two of these walls installed in each living unit. These beams and columns will be joined to the wood core using the precast concrete joint material (PCa joint material) that forms the core of the Shimizu Hy-wood technology and offers superior earthquake resistance, fire resistance, and workability.

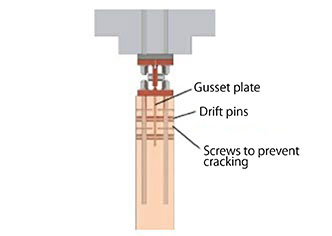

For one-hour fire resistance, Shimizu will use Slim Fire-Resistant Wood for the columns, studs, and beams of the core structure. Slim Fire-Resistant Wood is a product that Shimizu developed jointly with Kikusui Chemical Industries Co., Ltd. and has been certified by the Ministry of Land, Infrastructure, Transport and Tourism. Shimizu also anticipated the need to make this product resistant to water and weather so that the columns and beams could be installed on the building’s exterior to increase the appearance of wood.

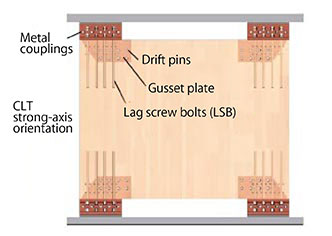

Shimizu will use CLT (cross-laminated timber) panels for the earthquake-resistant walls. CLT consists of multiple layers of sawn timber glued together with the wood grain of each panel oriented perpendicular to the preceding panel. The CLT earthquake-resistant walls will be inserted into the RC column and beam frame that runs longitudinally along the center section of each building floor. These walls will bear a maximum of 60% of the seismic force along the long side of the building and will also function as partitions and finishing material.

In addition to the structural components and materials, Shimizu will also use wooden materials for the surfaces of the RC earthquake-resistant walls between apartment units, flooring material, and the exterior walls of the gable sides. Part of the floor will be composite flooring consisting of RC and CLT. The CLT panels will function as supplementary materials to improve the vibration resistance and sound insulation of the formwork and RC floors during construction and also as the finishing materials for the ceiling surface. The wooden materials will give the living spaces the feel of wood.

The use of wood is expected to increase in the future as Japan`s “Act for Promotion of Use of Wood in Public Buildings” is enforced. Shimizu will continue to develop technology for greater use of wood materials and wood construction in buildings.

≪For Reference≫

Construction Overview

| Name of construction project | Chayagasaka Apartments Reconstruction Project |

|---|---|

| Location | 1-29-2 Akasakacho, Chikusa-ku, Nagoya |

| Size | 1 basement floor, 4 floors above ground; building area: 799.86 m2; total floor area: 3,152.55 m2 |

| Ordered, designed and built by | Shimizu Corporation |

| Construction period | December 2018 to February 2020 |

Construction Plan

Shimizu Hy-wood

Shimizu Hy-wood, uses reinforced concrete joint material to join and unify columns or columns and beams for different types of structures made of wood and reinforced concrete or steel. This enables Shimizu to use wood in the living spaces to meet various needs. The reinforced concrete joint material provides superior earthquake resistance, and workability, while limiting thermal conductivity and delaying the burning of wooden columns during a fire.

Slim Fire-resistant Wood

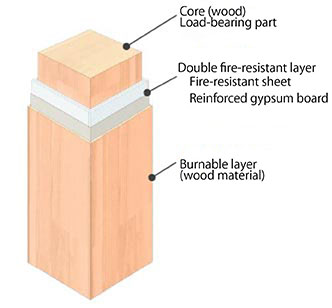

The special characteristic of Slim Fire-Resistant Wood is that the fire resistant layer combines different materials consisting of a fire resistant sheet and reinforced gypsum board to form a double fire resistant layer. When heated during a fire, the thin fire resistant sheet foams, creating an insulating effect, and the reinforced gypsum board absorbs heat and acts as thermal insulation. This increases the fire resistance of the fire resistant layer and enables the thickness to be limited to 32 mm. Making the fire resistant layer thinner makes it possible to reduce costs and increase efficiency and open space.

“Sustainable Architecture Promotion(Wooden Architecture Category)”

This project is a leading example of a large-scale wooden building construction using a large amount of wood - a sustainable and recyclable resource. The goal is to contribute to the development of technology related to wooden structures while also educating the public and encouraging the widespread use of wood and wood-based materials.

The information contained in this news release is the current information on the date of publication. Please be aware that this information may have changed by the time you view it. Please contact the company to inquire for further details.