May 24, 2018

Shimizu Corporation (President: Kazuyuki Inoue) has obtained certification of reliability for the two-hour fire resistance specification of its Slim Fire-Resistant Wood columns from the Ministry of Land, Infrastructure and Transport. These fire-resistant columns were jointly developed with KIKUSUI Chemical Industries Co., Ltd. The two-hour fire resistance of Shimizu Hy-wood, a wooden hybrid frame that joins Slim Fire-Resistant Wood columns to steel beams was also verified through independent testing.

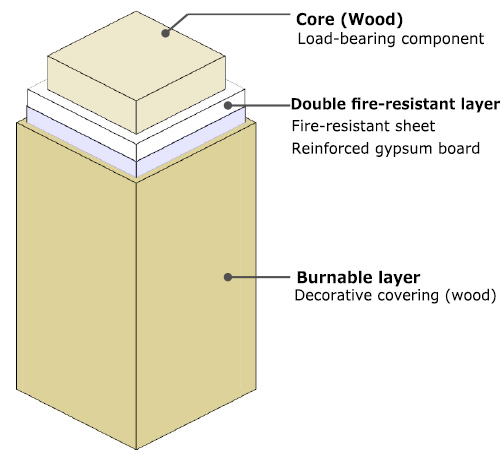

Typical fire-resistant wood columns consist of a wooden core at the center of the column to bear the weight of the building, a fire stoppage layer to prevent fire from spreading to the core, and burning marginal layer surface covering made of wood. In the case of Slim Fire-Resistant Wood, the fire stoppage layer combines different materials consisting of intumescent fire protective sheet and reinforced gypsum board to form a double fire stoppage layer. When heated during a fire, the thin intumescent fire protective sheet foams, creating an insulating effect, and the reinforced gypsum board absorbs heat and acts as thermal insulation. Moreover, the joints, which are the weak points for fire-resistant materials, also have strong fire resistance performance while limiting the thickness. This was achieved by staggering the two layers over the joints.

The specifications for the certified two-hour fire resistance require that the core be covered by a 55 mm-thick dual fire stoppage layer composed of reinforced gypsum board and intumescent fire protective sheet, which is then covered by a 15 mm-thick layer of burning marginal layer covering. The corners of the core, which are susceptible to high incidental heat transfer, are beveled (the corners are shaved off), and filled with gypsum board (gypsum-based plaster board).

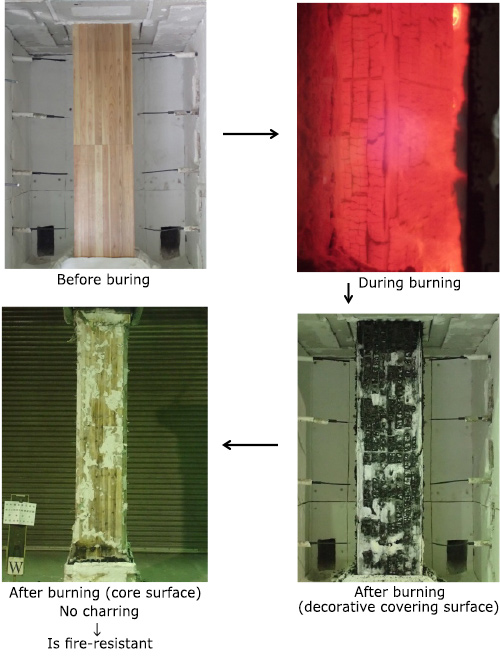

In the fire resistance certification testing, a test sample 70 cm square and 3.5 meters long (3 meters to be heated), produced according to the two-hour heat resistance specifications, was heated in a refractory furnace. The temperature of the core surface was measured over a period of approximately six hours after being heated for two hours until the temperature of the furnace interior reached the specified 1,050ºC. The maximum temperature attained was less than 110ºC, about half of the 260ºC critical temperature required for the wood material to char. After the heating was complete, the fire stoppage layer was peeled off of the core to confirm whether the surface of the core was charred. There was no evidence of charring whatsoever, thereby verifying the two-hour fire resistance performance.

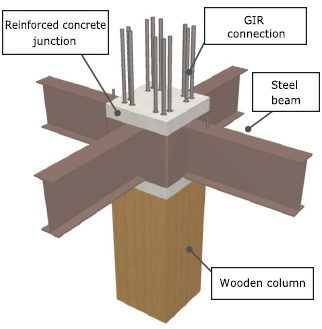

The thermal conductivity of the Shimizu Hy-wood column and beam joint material forming a wooden hybrid frame was also verified through independent testing of fire resistance. The testing verified that the intervention of the reinforced concrete joint material would limit thermal conductivity that would have an adverse effect on the core even if the steel beams became hot during a fire. More specifically, the steel beams, reinforced concrete joint material, and wooden column were heated until the furnace temperature reached 1,050ºC. Testers continued to take measurements after the heating was stopped. The results showed that the steel beams reached a maximum of 500ºC, but the thermal absorptive effect of the reinforced concrete prevented the temperature of the core surface from exceeding 100ºC at the intersection of the reinforced concrete joint material and the wooden column.

The certification of Slim Fire-Resistant Wood for two-hour fire resistance means that it is now possible to use it for wood columns in buildings up to 14 stories tall. The performance on heatresistance also enables the heat-resistant layer and the burning marginal layer covering to be around 20% slimmer than the slimmest competing products. This is an advantage because it enables Shimizu to provide building spaces with a cleaner profile. In the future, Shimizu plans to propose use of Slim Heat-Resistant Wood in building mid- to high-rise fire-resistant buildings such as offices, commercial facilities, and schools. We will also begin designing fire-resistant wood housing complexes using Slim Fire-Resistant Wood columns and beams in the near future. We also intend to work on development of fire-resistant wood flooring and other products using CLT (Cross-Laminated Timber) to expand the uses for fire-resistant wood materials.

≪For Reference≫

KIKUSUI Chemical Industries Co., Ltd.

| Address | Nippon Life Insurance Hirokoji Building, 2-19-25 Nishiki, Naka-ku, Nagoya 460-0003 TEL 052 300 2222 |

|---|---|

| Date of establishment | May 21, 1959 |

| President | Hitoshi Yamaguchi |

| Capital | 1,972 million yen |

| Business description | Manufacture and sale of specialty functional materials and construction finishing materials Manufacture and sale of building/civil engineering materials, and machinery and equipment |

Shimizu Hy-wood

Use of precast reinforce concrete joint material joins and unifies columns or columns and beams of different types of structures made of wood and reinforced concrete or steel. Openings to connect column and beam structures are created in the reinforced concrete joint material. For example, when connecting wooden columns vertically, the steel bars (main bars) that attach to both ends of the wooden columns are inserted through the insertion holes created in the joint material from the top and bottom, connected by mechanical coupling, and filled with mortar. When connecting wooden or steel beams with reinforced concrete material, they are joined by gusset plates and other couplings installed on the side of the reinforced joint material.

Photos from certification testing of two-hour fire resistant columns

Composition of Slim Fire-Resistant Wood

The information contained in this news release is the current information on the date of publication. Please be aware that this information may have changed by the time you view it. Please contact the company to inquire for further details.