October 16, 2017

Shimizu Corporation (President: Kazuyuki Inoue) recently received certification from the Building Center of Japan (BCJ) on its Dynamic Screw, a high-performance vibration damper for long-period earthquake motion, which Shimizu jointly developed previously and has already used in 13 projects. The BCJ certifies the aseismic performance of the Dynamic Screw and its reliability as a method used in the design of earthquake-resistant buildings. Acquisition of the certification will simplify the part of the design screening process related to the damper when evaluating the structural performance or confirming the construction of a building in which the Dynamic Screw will be used. This will consequently shorten the time from design period up to the point of completing examination. This is also the first time that BCJ has awarded certification to any type of vibration damping technology, including aseismic design techniques.

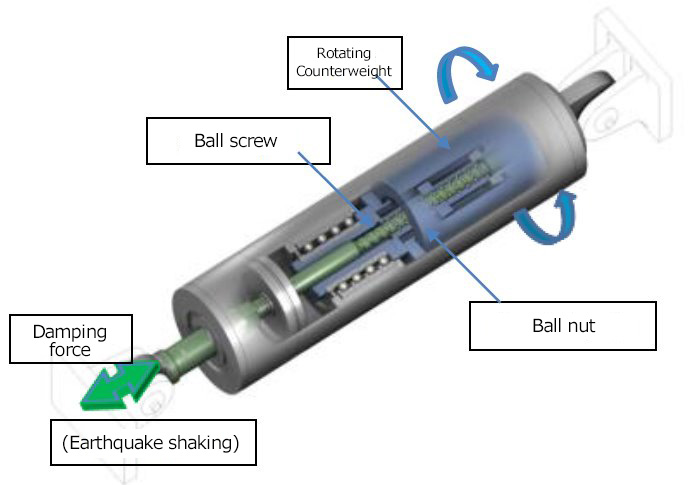

The Dynamic Screw is a vibration damping device that is installed in the columns and beams of a building frame. The unique feature is that it absorbs the energy of the tremors shaking a building during an earthquake by converting it to rotation of the counterweight. Rotation of the counterweight enables the device to exert a force (inertial mass effect) equivalent to between 4,500 and 7,000 times the actual weight of the counterweight, and this reduces shaking of the building. A vibration damping device normally uses an attunement system that moves a counterweight attuned to the shaking period of the building to suppress the shaking. Such systems theoretically require a counterweight that is around 3% of the building's weight. The Dynamic Screw uses the inertial mass effect mentioned above to manifest the same effect with a weight of only 1/4,500 to 1/7,000 of the theoretically required weight.

In acquiring the certification, we sought to specify and standardize the device size and performance to three types having an internal mass effect of 2,500 tons, 4,000 tons, and 6,500 tons, respectively. Shimizu formulated the structural performance based on the results of performance verification testing of each type that was conducted over the course of nearly one year, built an analytical model capable of accurately reproducing the movement (dynamic behavior) according to the shaking of the building, and established practical aseismic design techniques for buildings that apply Dynamic Screw technology. The use of this type of analytical model and design techniques enables the selection of the optimal type of device based on the particular structural characteristics of a building, from low-rise buildings all the way up to ultra-high-rise buildings. It also enables the efficient design of a building that can demonstrate optimal vibration damping performance, according to the needs. This standardization also enables a 30% reduction in the cost of manufacturing dampers, compared to the cost for individually designed dampers.

Shimizu will shortly begin construction of the 14th property using the Dynamic Screw. It is the ultra-high-rise building in the Takeshiba Waterfront Development Project of East Japan Railway Company, a 26-story building that will be built in the Takeshiba district of Minato City. Six 6,500-ton Dynamic Screws will be installed on the fourth floor of this building to effectively control the so-called secondary mode rolling sway of the building caused by long-period earthquake motions.

In the future, Shimizu intends to propose the optimal vibration damping for buildings by using the Dynamic Screw, the rooftop installation of the Shimizu Swing Mass Damper, which also counteracts long-period earthquake motion, and a combination incorporating the Dynamic Screw into the Swing Mass Damper. We anticipate these proposals to result in orders for new ultra-high-rise buildings and renovation work.

<< For Reference >>

Conceptual Diagram of the Dynamic Scre

Overview of the High-rise Building in the Takeshiba Waterfront Project

| Commissioned by: | East Japan Railway Company |

|---|---|

| Planned Sites: | 22-1 Kaigan 1-chome, Minato-ku, Tokyo |

| Scale: | 2 floors below ground, 26 floors above ground Height: Approx. 122 m Total floor area: Approx. 65,700 m2 |

| Structure: | Steel structure, partial reinforced-concrete structure and steel reinforced-concrete structure |

| Designer: | JR East Design Corporation Collaborating on structural design: Shimizu Corporation |

| Construction Company: | Shimizu Corporation |

The information contained in this news release is the current information on the date of publication. Please be aware that this information may have changed by the time you view it. Please contact the company to inquire for further details.