August 24, 2017

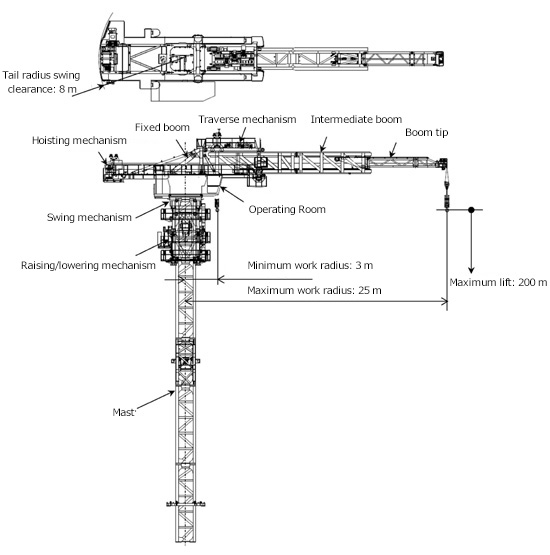

Shimizu Corporation (President: Kazuyuki Inoue) has developed Exter, the world's first horizontal sliding crane that can freely adjust the work radius horizontally via a boom that expands and contracts, as a new construction machine that will play a part in supporting the newly configured Shimz Smart Site next-generation production system. Machine Nos. 1 and 2 were recently completed. The specifications for both machines are a rated load of 12 tons (at maximum lifting capacity), a work radius of 3 to 25 meters, and a lift distance (height of load lifted) of 200 meters.

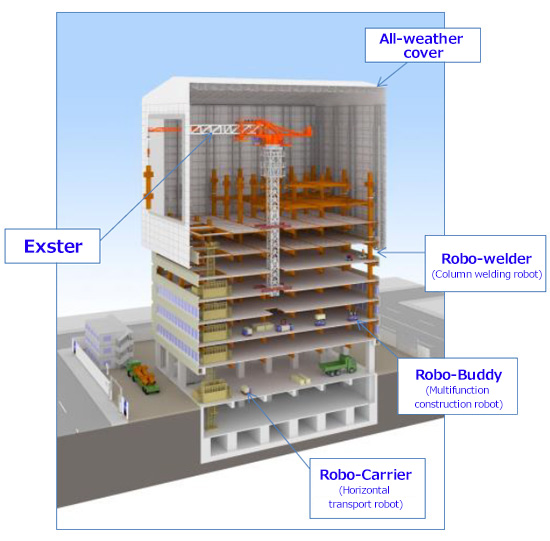

The Shimz Smart Site is a production system designed for building construction work. It consists of Exter and various types of autonomous construction robots. Exter is a tower crane that is equipped with a newly developed boom that expands and contracts horizontally. The design enables Exter to work efficiently under the all-weather cover installed on top of the entire building. The all-weather cover fulfills the role of blocking wind, rain, and direct sunlight, and therefore helps to improve the work environment and productivity. There have been construction and dismantling methods in which the building was covered by an all-weather cover before, however, aligning the layout of the ceiling crane used to lift things to the planar shape of a building, and the high cost of reinforcing a structure so that it could support the weight of a crane made it difficult to use these methods.

The boom, which expands and contracts horizontally, is divided into three segments. The largest boom segment is fixed at the crane neck, and houses two more boom segments within that, both an intermediate segment and the tip. When the boom is extended, and it extends from the tip of the boom. When lifting materials, the boom is extended and protrudes outside from an aperture created on the side of the all-weather cover. It lifts up the material from the ground and then the boom is retracted to bring the material inside the all-weather cover. Inside the all-weather cover, the boom is extended or retracted and rotated horizontally to lower the load at the designated position. Moreover, the boom senses the relationship between the location of the cover and the tip of the boom when rotating horizontally, thereby preventing accidental contact of the boom with the cover.

Exter and the all-weather cover can also be used in the work of dismantling an ultra-high-rise building. After the all-weather cover is first placed over the top of the building, the cutting and dismantling of the building then proceeds, and Exter lowers the cut sections outside. The cover greatly reduces the burden on the environment by preventing noise transmission and scattering of dust. The highest point of Exter is 20 to 25 meters lower than conventional tower cranes with telescoping booms, so it could also be used in construction in aviation restriction zones and for construction on building top locations where microwaves pass through.

Shimizu intends to work to improve productivity at building construction sites by striving to roll out use of Exter and the robots and construction equipment laterally to other types of projects in addition to using the entire Shimz Smart Site system.

<< For Reference >>

Completed Exter (on the grounds of the Yasuura Plant of IHI Transport Machinery Co., Ltd. (in Kure, Hiroshima Prefecture))

Exter Assembly Diagra

Conceptual Diagram of the Shimz Smart Site

This is a next-generation production system developed for the purpose of improving productivity at building construction sites, reducing strenuous and repetitive work, and improving the efficiency of inspection and management. Computerizing the construction process with BIM (Building Information Modeling) at the core will enable construction workers to collaborate with autonomous robots equipped with the latest technology as construction proceeds. The sites where the individual robots and construction machinery will be used has already been determined, and we will begin construction of a high-rise building using the entire system in the Kansai area early next year. Our goal is to reduce the human labor required by 70% or more in the types of construction where robots are used through completion.

The information contained in this news release is the current information on the date of publication. Please be aware that this information may have changed by the time you view it. Please contact the company to inquire for further details.