July 28, 2017

Shimizu Corporation (President: Kazuyuki Inoue) recently developed the Shimizu Swing Mass Damper, a new type of seismic damping device for rooftop installation on ultra-high-rise buildings subject to complex shaking to counteract long-period earthquake motion . The foremost characteristic is that the movement of the seismic damping device is controlled by another seismic damping device inside the device. This enables damping of shaking in two different periods with one device.

When an ultra-high-rise building has a planar shape that is nearly square, it sways at a natural period that is nearly the same, regardless of the direction. When the building is rectangular in shape, it experiences two types of sway with differing periods in the direction of the building's length and width, despite the fact that it is the same building. To effectively absorb the shaking with different periods, it is preferable to install seismic damping devices for each direction that are matched to the period of each direction. However, there is not always sufficient space for that on a rooftop. Moreover, the weight of the counterweight for one rooftop-type vibration damping device is on the order of several hundred tons, and the total weight exceeds 1,000 tons, so it is desirable to reduce the weight.

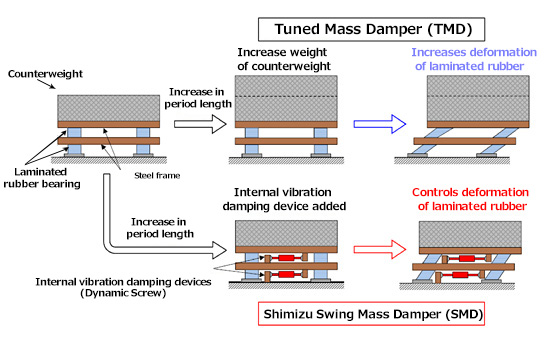

We developed the Shimizu Swing Mass Damper (SMD) to meet the need for this sort of rooftop vibration damping device. The basic structure of an SMD is similar to a four-legged table. The surface of the tabletop is a steel or concrete counterweight, and the four legs are each made of two-layer laminated rubber bearing. Inside the device, there is a steel frame that is connected to the laminated rubber bearing, an internal vibration damping device connected to the interior of the frame, and an oil damper that attenuates the shaking of the counterweight. During an earthquake, the counterweight deforms the laminated rubber bearing and moves in a direction that counteracts the shaking of the building.

Laminated rubber bearing is normally used in seismically isolated buildings. The period of the counterweight motion can be tuned to the long-period shaking of an ultra-high-rise building by adjusting the hardness and thickness of the laminated rubber bearing. The internal damping device that characterizes an SMD is a device that we adapted from the Dynamic Screw, which Shimizu developed jointly with Kayaba System Machinery Co., Ltd. and NSK Ltd. This device originally converted the shaking of an ultra-high-rise building into a rotating motion, thereby manifesting a damping effect. Its role as an internal damping device is to control the deformation of the laminated rubber bearing in a specific direction, while lengthening the period of the SMD. This mechanism enables the damping of shaking with two different periods with just one device.

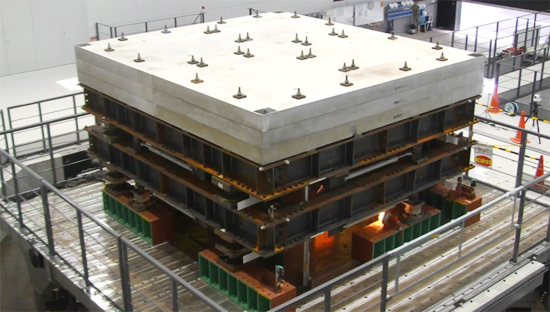

We built a reduced-scale model of an SMD equipped with a 30-ton counterweight, conducted a vibration test on a large shaking table at our Institute of Technology and confirmed that one device could respond to two types of shaking with differing periods. We also performed a simulation using the SMD in a model of a 30-story building replicated from the structural data of an existing ultra-high-rise building with natural periods of 3 seconds and 3.5 seconds for the long and short sides. Based on damping theory, we installed three SMDs with counterweights weighing 400 tons, estimated at around 3% of the building's weight. These achieved a maximum 52% reduction in shaking in the direction of the building's length and a 43% reduction in shaking in the direction of the building's width in response to a motion simulating an earthquake in the Nankai Trough. We expect these reductions to enable prevention and mitigation of damage to the building structure and to secondary components and materials such as the ceilings and walls. Three vibration damping devices of the existing type with counterweights weighing the same amount installed could only be expected to reduce shaking in the direction of the building's width by a maximum of 21%. To match the damping effectiveness of the SMD would require the installation of several vibration damping devices with differing periods and counterweights weighing 1,600 tons in total.

In the future, we can expect an increase in new construction of and renovation work on ultra-high-rise buildings to counteract long-period earthquake motion since we must prepare for earthquakes in the Sagami Trough in addition to the Nankai Trough, based on the Ministry of Land, Infrastructure, Transport, and Tourism's policy on response. Shimizu will leverage the SMD and Dynamic Screw technologies in expanding its proposal activities with the intent of securing project orders.

<< For Reference >>

SMD during a shaking test

Lengthening the Period of a Damping Device with an Internal Damping Device (Dynamic Screw)

The information contained in this news release is the current information on the date of publication. Please be aware that this information may have changed by the time you view it. Please contact the company to inquire for further details.