Historical Structure Passing Traditional Skills on to Future Generations Preservation and Repairing of Nirayama Reverberatory Furnaces, a World Heritage Site

The year-long preservation and repairing of the Nirayama Reverberatory Furnaces, a World Heritage site, was completed in October 2021. The beautiful form of the two twin reverberatory furnaces is now completely visible.

The Only Surviving Reverberatory Furnaces Used for Casting Cannons in Japan

The Nirayama Reverberatory Furnaces was completed in November 1857 as a foundry for casting Western-style cannon and operated to 1864. This is the only surviving reverberatory furnaces actually casting cannons in Japan.

Designated as a National Historic Site in 1922, the Japanese Ministry of Economy, Trade and Industry designated the furnaces as a modern industrial heritage site in 2007. In 2015, the Nirayama Reverberatory Furnaces was registered as a World Heritage site as one of the Sites of Japan’s Meiji Industrial Revolution at the 39th session of the UNESCO World Heritage Committee.

The furnaces are called “reverberatory furnaces” because they operate by reflecting the heat and flames generated from burning coal and other fuels off the furnace ceiling and concentrating it in one spot. This achieves a high temperature of one thousand and several hundred degrees and makes it possible to melt iron for casting.

First Preservation and Repairing in 32 Years

This preservation and repairing are done the first for the furnaces since they were designated as a World Heritage site in 2015 and has been 32 years since the last major preservation and repairing in 1989.

The bricks, stones, and paints on steel frame of the smokestacks of the reverberatory furnaces had visibly deteriorated over the past 32 years, so Izunokuni city made the decision to have preservation and repairing done in 2018. The Japanese Association for Conservation of Architectural Monuments subsequently took charge of the concept and working designs and Shimizu was awarded contract in 2020.

Stupendous Tasks

Preservation and repairing began with a survey. We had to check the more than 10,000 bricks to determine what type of repairs were needed. The first task was to visually inspect all of the bricks, one by one. We then gauged the degree of deterioration of the damaged bricks. This required looking at each brick multiple times to take photos for the report.

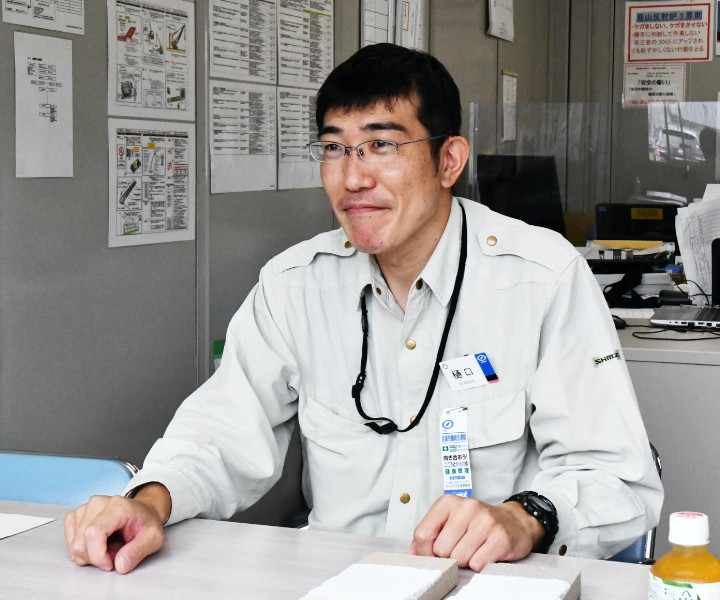

Takashi Higuchi in the Shizuoka office responsible for the preservation and repairing commented, “We were not used to the work in the beginning and only managed to inspect around 100 bricks an hour. It was stupendous and I wondered if we would ever reach the end. However, we gradually began to work faster and ultimately became able to judge the “faces” of the bricks just by looking at them.

The results of the detailed investigation revealed that 1,298 of the 14,457 facing bricks needed repair. Mr. Higuchi added, “It was only about 35 cm wide between the two smokestacks in the middle. Surveying this part took about three times longer than usual because it was narrow and hard to see, and I could not move my body.”

After the survey was complete, the surfaces of 850 spots with relatively little deterioration were repaired with mortar and plaster. The 240 spots with advanced deterioration were stabilized by affixing replacement bricks to the surface. New bricks were used to replace all or part of the bricks in 208 spots that were extremely deteriorated.

Contributions to Preservation and Repairing of Cultural Heritage Sites

Higuchi said he cannot forget the words of the veteran construction manager who is designated as a Shimizu master trainer in traditional construction methods when he came to assemble the scaffolding, “There are very few in Shimizu who are experienced in this kind of work and it is usually performed solo. You probably have many concerns over whom to advice for and how to proceed with the repairs. I won’t leave you to handle it alone.”

These were the words of an expert who had been responsible for the building Daijokyu complex, ritual venue for imperial enthronement ceremony and preservation and repairing of the Izumo Taisha Shrine. Higuchi reflected, “This eased my mind because I could get advice from him if something arose and he would help somehow. I was able to reach this point because of these words.”

The Nirayama Reverberatory Furnaces is now visible after one year of renovation. Traditional construction techniques are the basics where Shimizu began, and we will continue to pass on these techniques to future generations as we utilize the expertise we have accumulated to contribute to the preservation and repairing of cultural heritage sites.

The information posted here is the current information on December 22, 2021.

Please be aware that this information may have changed by the time you view it.