Evolving Transportation InfrastructureNew Artery for Tokyo

Connected by Japan's Largest Shield Machine

Near the Oizumi Junction

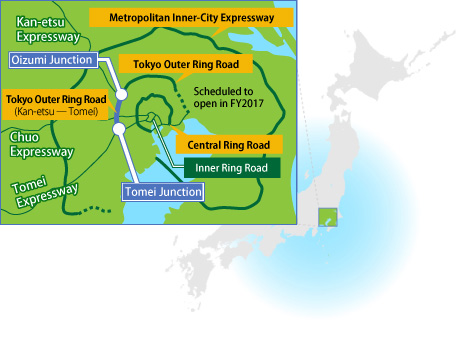

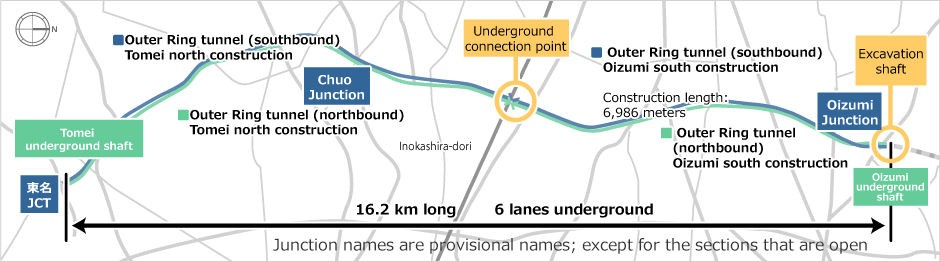

Construction is progressing at a fast clip on the Tokyo Outer Ring Road, which is designed to resolve the traffic jams in the Greater Tokyo Area and spur regional economic development. The point that is drawing interest in the completion of the road is the deep underground tunnel that will stretch for 16.2 kilometers between the Oizumi junction and the Tomei Junction (provisional name). Of the two northbound and the two southbound tunnels, Shimizu is in charge of the Oizumi Minami (south) excavation work on the (southbound) Outer Ring tunnel from the Oizumi Junction side.

Aiming for Rapid Completion of the Three Ring Roads Circling the Greater Tokyo Area

The Tokyo Outer Ring Road (Outer Ring) will be the last of the ring roads completed. These roads fulfill the function of dispersing the traffic congestion in the inbound direction and connecting the Tomei, Chuo, Kan-etsu, and other expressways. Shimizu is in charge of the roughly 7 kilometers of the 16.2-kilometer tunnel connecting sections of the city beginning from the northside, and will connect it underground to the tunnel from the south side near the Inokashira-dori intersection.

The tunnel will be excavated deep underground*1 at more than 40 meters below ground level. Completing this quickly will require rapid construction of the largest shield tunnel ever seen.The tunnel will be excavated deep underground*1 at more than 40 meters below ground level. Completing this quickly will require rapid construction of the largest shield tunnel ever seen.

1 Refers to deep underground in a zone that the landowners will not use. The use of this underground space for public purposes such as improving urban function is a new option.

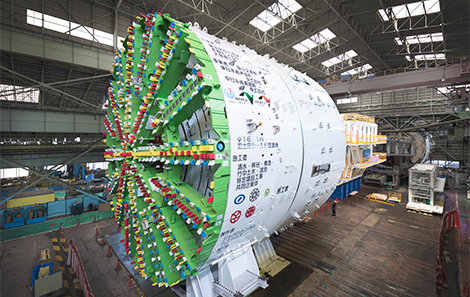

Massive Shield Machine with an Outer Diameter of 16.1 Meters for Deep Underground Excavation

We brought in Japan's largest shield machine for this project.

With an outer diameter of 16.1 meters, it would reach to the 4th floor of a typical office building. The massive size of this machine exceeds the diameter of the shield machine used to build the Trans-Tokyo Bay Highway (Aqua Line), which was 14.14 meters in diameter. We are using this machine to fulfill the unprecedented work requirement of excavating a maximum of 30 meters per day, on average.

Transporting Excavated Soil by Belt Conveyor to Reduce the Environmental Burden

The earth excavated by the shield machine is transported to a temporary site around 6 kilometers away from the excavation shaft by a belt conveyor installed over an expressway.

The plan is to substantially reduce the construction vehicles needed near the excavation shaft, thereby lessening traffic congestion, and other impacts on the surrounding environment.

Protective panels are installed on the top and sides

Overcoming Highly Difficult Technical Issues

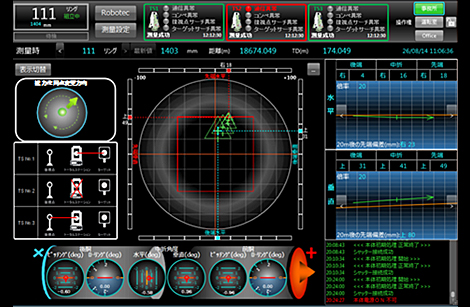

The majority of the tunnel for this line will be built deep underground. However, the ground cover*2 is only 5 meters in some sections. It therefore demands management of extremely high-precision excavation and every precaution to prevent subsidence of the surrounding ground. We are verifying the optimal placement of cutter bits that can withstand excavation over a long distance as we proceed with excavation. We are also actively working to incorporate CIM*3 and computerization of construction, and are working to ensure quality, a safe management system, and to improve productivity.

2 The thickness of the ground surface from the upper end of the structure built underground, or the depth from the ground surface.

3 Construction Information Modeling: The concept and principle of using the latest ICT technology to share information at each stage to plan, design, execute, and manage the construction production system, in order to build an efficient, high quality construction production system.

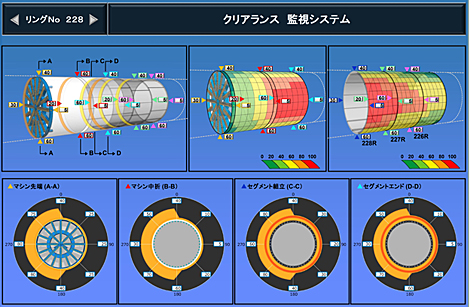

Three total stations are used to take simultaneous measurements, and produce instant measurements of shield machine positioning.

The clearance between the outbreak and the external surface of the shield machine is ascertained by tracking the copy cutters. The clearance between the internal surface of the shield machine and the segments is ascertained by measuring tail clearance. Both types of clearance are visualized in 3-D and collectively managed.

Preparing for Commencement of Shield Excavation

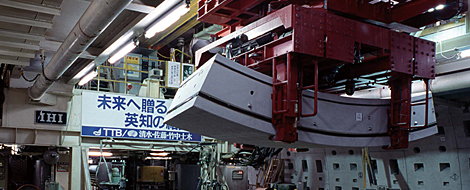

Shimizu is currently working on preparatory construction for shaft excavation and shield machine assembly (a joint venture that Shimizu is heading will also build the Oizumi shaft).

Once the shaft has been excavated, a massive crane and a structure that provides the counterforce for the shield machine to move forward will be also assembled at the starting point. Around 200 large trailers will be used to transport parts from the factory where the shield machine was produced. These will be assembled onsite before the tunnel excavation begins.

Tokyo Bay Aqua Line was a Milestone in Shield Technology

The Trans-Tokyo Bay Highway (Aqua Line), described as the last national project of the twentieth century is an indispensable part of Shimizu's history of shield construction. At the time, it was the largest shield construction in the world, with a shield having an ultra-large external diameter of 14.14 meters and a section distance of 2.8 kilometers per section.

The tunnel bottom in the section built by Shimizu was 50 meters below sea level. The highwater pressure and extremely soft clay earth made construction difficult, but Shimizu completed the section faster than other sections by working to fully automate segment*4 assembly and improve segment supply capacity. Shimizu also built a foolproof quality and safety management system by introducing an integrated excavation management system and an automatic measurement system, thereby guiding the project to success.

4 Segments are the blocks that form the walls of the tunnel.

The Technology Developed through Numerous Difficult Construction Projects is Used Actively

Shimizu used the construction of the Trans-Tokyo Bay Highway (Aqua Line) as an opportunity to dramatically improve its shield technology.

The high-level technical capabilities required in the construction also led to new orders. Tunnel excavation was completed in 2001, and we successfully completed the difficult construction of the Imaigawa River Underground Regulating Pond, which was put into commission in April 2014, under high water pressure and deep underground where the maximum ground cover reached 85 meters. In recent years, we have successfully completed many difficult projects, including the Metropolitan Expressway Central Circular Shinjuku Route Ohashi Junction Tunnel, which involved the construction of closely spaced road tunnels that were stacked in double-decker fashion and had steep curves; and the continuous grade separation near the Chofu Station in which four closely spaced railway tunnels for routes in both directions were excavated with an extremely shallow ground covering, directly beneath an operating rail line.

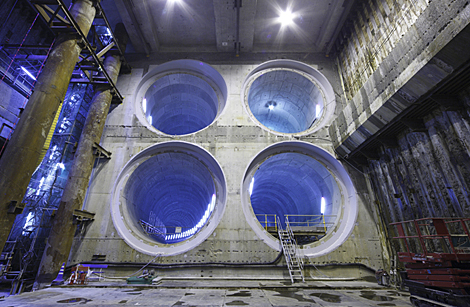

We also successfully mastered problematic aspects in the shield construction that is currently underway, and have received consistently high praise for it both inside and outside of the industry. This construction involves building four ramps for the Baba Junction on the northbound Yokohama Loop on the Metropolitan Expressway (the main route opened for operation in March 2017), and the highly difficult conditions included a 1.3-meter ground covering which is the barest minimum, steep curves with a radius of 50 meters, and a longitudinal slope of -7.6%.

The technology developed for these difficult projects is being used in the deep underground tunnel on the Tokyo Outer Ring Road (Outer Ring).

the Central Ring of the Metropolitan Expressway

on the Yokohama Ring of the Metropolitan Expressway

Innovation in Building Urban District Infrastructure

Further growth in large-scale shield construction under extremely demanding conditions is anticipated in the future.

Monitoring technology that can "visualize" the parts that cannot be seen will be required for that.

To perform safe, steady shield excavation over long distances or deep underground, there will need to be continuous monitoring and visualization of shield machine wear, excavation conditions in increasingly harder ground the deeper the excavation goes, and other aspects.

Shimizu will establish reliable monitoring technology for shield excavation through our work on construction of the Tokyo Outer Ring Main Route Tunnel (southbound), which is the largest shield tunnel in Japan. This will open up a new stage in shield construction technology.

Ohashi Tunnel on the Central Ring Shinjuku Route of the Metropolitan Expressway

Column

What is the Shield Construction Method?

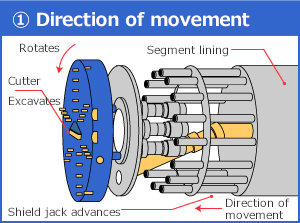

This refers to the technology for building a tunnel. In this method, a tunnel is excavated underground by a shield machine (a round boring machine) equipped with many teeth (cutter bits) on the front surface. After the tunnel is excavated, segments (blocks) that have been produced at a factory are assembled to form the walls of the excavated tunnel. A tunnel excavated using this method is called a shield tunnel.

-

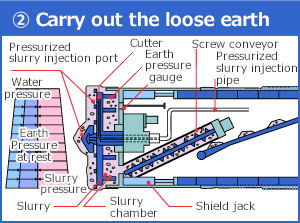

The cutter is rotated, and the shield machine excavates a tunnel underground -

The excavated earth is loaded on the screw conveyor, transferred to the belt conveyor, and then carried out of the tunnel. -

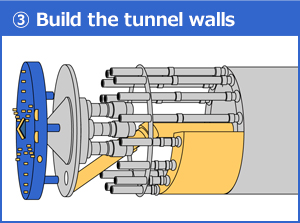

The tunnel walls are built by assembling segments produced at a plant in advance.

The information posted here is the current information on September 1, 2017.

Please be aware that this information may have changed by the time you view it.