Tracing Shimizu’s Work in Prestressed Concrete (PC) BridgesThe story behind Shimizu’s long span bridge achievements

Onahama Marine Bridge(Fukushima Prefecture)

The Onahama Marine Bridge, a prestressed concrete (PC) bridge built by Shimizu Corporation, received the Tanaka Award from the Japan Society of Civil Engineers in June 2018.

This award is the most prestigious award in bridge sector. It is named after the late Dr. Yutaka Tanaka, who is called the father of the bridge and structural engineering in Japan.

Here, we introduce the story of how Shimizu, a latecomer to the PC bridge sector, came to accumulate a track record and earn numerous Tanaka awards from the Japan Society of Civil Engineers.

Entering into the PC Bridge sector with the Polensky & Zöellner (P&Z) Construction Method

A PC bridge is a bridge that uses the prestressed concrete as the main structure. Concrete is prestressed by tensioning high-strength steel tendons, producing compression in the concrete volume, prior to supporting any load. It is capable of withstanding higher loads than regular reinforced concrete, making longer spans (distance between piers) possible. Today, many of the new concrete bridges in Japan are PC bridges.

The history of PC bridges built by Shimizu began with the introduction of the P&Z construction method*1 in 1977 from what was then West Germany.

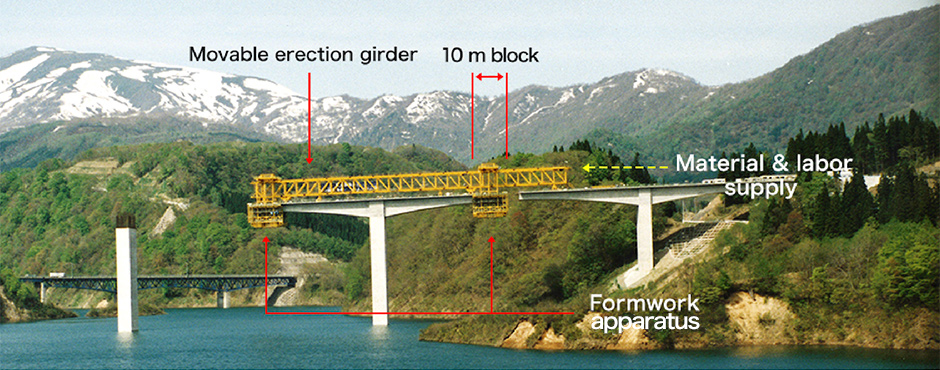

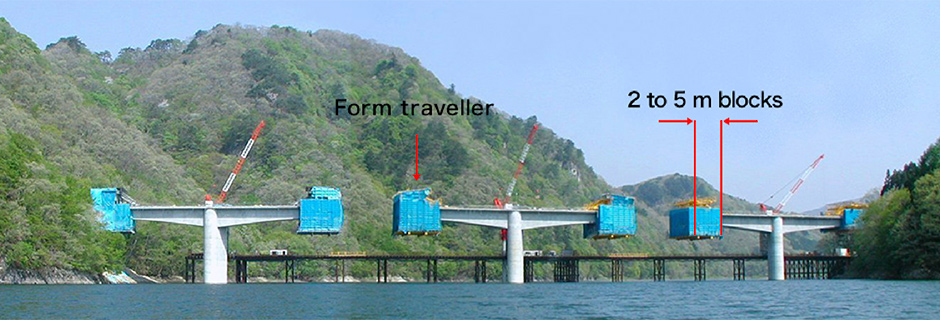

At that time, PC bridges of great length were exclusively built by the cantilever erection method*2, which uses a special movable steel structure for the formwork called “form traveller”. Shimizu, which had entered the PC bridge sector quite late, introduced the P&Z construction method, a cantilever erection method that uses a launching gantry, or movable erection girder. Shimizu took on the challenge to stand out on the PC bridge sector by using this new construction method, which requires absolutely no work on the land.

*1P&Z construction method: This method enables construction of the superstructure without temporary piers, so it is suitable for bridges that span large rivers and valleys. The bridge body is divided into segments built by a formwork suspended from the movable girder. A block of about 10m length can be built at a time, larger blocks comparing it to the “form traveller” of the cantilever construction method, enabling rapid construction. (Developed by Polensky & Zöellner of West Germany)

*2Cantilever construction method using form traveller: The blocks are built by form travellers suspended from each end of the bridge body. A block of about 2 to 5m in length can be produced at a time.

Challenging for Long Span

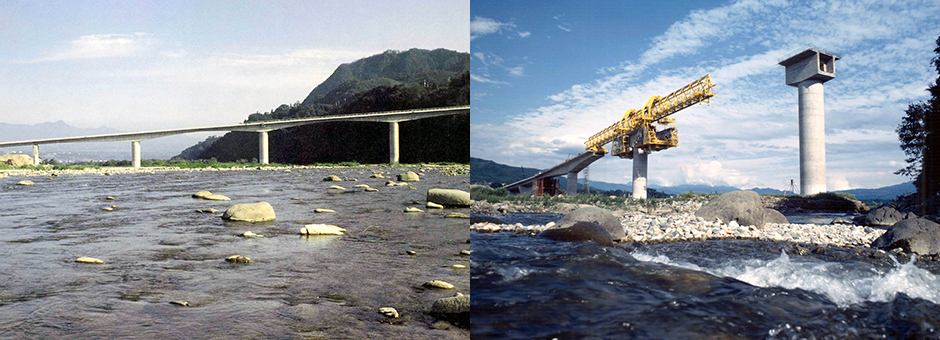

The starting point of PC bridges by Shimizu was the Tsukiyono Bridge in Gunma Prefecture, which spans the main branch of the Tonegawa River. The P&Z construction method was first used in Japan to build the superstructure of the Tsukiyono Bridge, which was completed in 1982. The bridge, which opened up a new area in bridge construction technology, was awarded the Tanaka Award by the Japan Society of Civil Engineers in 1982.

Shimizu subsequently expanded its track record in PC bridge construction, however, it is said that it is not the number, but the bridge span length that really reveals the technical capabilities in bridge construction. Shimizu launched an internal development project in 1985 and began working on developing technology for a PC cable-stayed bridge*3 with a construction style suitable for long spans.

*3PC cable-stayed bridge: A bridge structure consists of towers, stay cables, and the main girder. The main girder is supported by stay cables attached directly to the tower, enabling longer spans.

Shimizu’s wide effort led to a contract for the Notojima Nodo Bridge, the hoped-for cable-stay bridge with a long span of 230m, in 1995; followed by the Tenkenji Bridge, with a span of 219m in 1996.

Great Advances in Cable-Stayed Bridges with Long Spans

Shimizu took on the challenge of expanding its horizons to overseas projects as well. It used a large precast segment construction method*4 to build the Malaysia―Singapore Second Link Bridge that spans the borders of the two countries. With 1.7km length, it was the longest bridge built by a Japanese company with this construction method at the time it was completed in 1997.

*4Precast segment construction method: In this construction method, segments are cast in advance at a plant or casting yard, then joined at the bridge site and joined into a single unit by applying compression force.

In 2006, Shimizu also completed the Bai Chay Bridge, which spans the picturesque Ha Long Bay, a UNESCO world heritage in Vietnam. The bridge has a maximum span of 435m. This was a major accomplishment in the area of long cable-stayed bridges. The 435m span is the longest in Southeast Asia among single-plane PC cable-stayed bridges*5.

*5Single-plane cable-stayed bridge: A cable-stayed bridge in which the center of bridge girder is suspended from cables in a single plane. The single-plane PC cable-stayed bridge with the longest span in Japan is the Yabegawa Bridge.

The Yabegawa Bridge was completed in Japan in 2009. It is a PC cable-stayed bridge with three continuous spans and has the longest span in Japan with 261m.

In the Race to Become a Leading Company in PC Bridge Technology

The number of project biddings conducted under the “general evaluation system” has increased since the 1990’s. Shimizu has also worked actively to propose the technology that it possesses. For railway bridges, Shimizu proposed the P&Z construction method for the completion of the superstructure of the Narusegawa Bridge regardless the winter at construction; The Bridge was completed in 1999. The superstructure and substructure of the fin back bridge, known for its characteristic fin-like appearance, were completed in a total construction period of about two years.

Shimizu’s proposal in the design competition for the reconstruction of the Amarube Bridge, which has been certified as a modern civil engineering heritage, was selected and Shimizu received the contract in 2007. The design included the construction method.

The new Amarube Bridge is a PC extradosed bridge*6 with five continuous spans. The super structure was built using the cantilever construction method with form traveller. The section that connected with the existing tunnel on the Kyoto side was considered one of the most difficult constructions ever attempted in Japan. It involved rotating 5.2 degrees at 40m above the ground the bridge girder of 93m long, 4m wide and 3,820ton weight.

*6Extradosed bridge: Is a bridge type with a structure that combines the main characteristics of a prestressed box girder and a cable stayed bridge.

Amarube Bridge, Working on a Civil Engineering Heritage that Will Last 100 Years

Shimizu has completed a series of bridges including the Kakamigahara Bridge, a 594m long bridge with 10 continuous spans and a gently curved silhouette that was built in 2013; the Ota River Bridge, a mixed steel and concrete arch bridge that was 412m long built in 2014; and the Onahama Marine Bridge, a PC extradosed bridge with five continuous spans built in 2017.

Recipient of Numerous Tanaka Awards from the Japan Society of Civil Engineers

In recent years, Shimizu has grown to the point where it can take pride in its track record and technology in Japan as well, having received numerous Tanaka Awards from the Japan Society of Civil Engineers, the foremost authority on bridge design and construction.

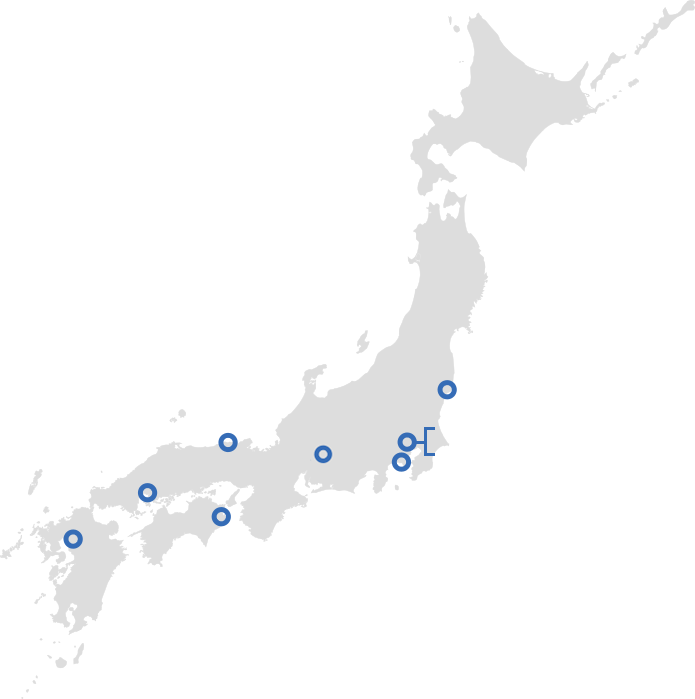

Tanaka Awards Received in Recent Years

- Onahama Marine BridgeA

- Tokyo Gate BridgeB

- Shiodome Bridge OverpassC

- Yokohama North (Loop) Line BridgeD

- Kakamigahara

BridgeE - Amarube BridgeF

- Ota River BridgeG

- Awa Shirasagi BridgeH

- Yabegawa

BridgeI

-

A

Fiscal Year 2017

Onahama Marine Bridge [new construction]

(Completed in 2017, Fukushima Prefecture)

The Onahama Marine Bridge (route section) is a PC extradosed bridge that is 510 m long and has five continuous spans. This bridge has proportion, created by the cables suspended from the low main tower. Shimizu achieved a design and structure that makes use of the scenery as a landmark in harmony with the surrounding environment. This was the first time an extradosed bridge was used as a harbor road bridge in Japan.

-

B

Fiscal Year 2011

Tokyo Gate Bridge [new construction]

(Completed in 2012, Tokyo)

This 2,618-meter-long bridge was built to strengthen international competitiveness by improving the efficiency of logistics in the Port of Tokyo by shortening transit time and reducing distribution costs for freight handled in the port. Shimizu determined that the main bridge should be a truss bridge due to the need to secure a 54.6-meter clearance beneath the bridge girder and a span length of 440 m to span Port Passage No. 3, while also taking flight restrictions for nearby Haneda Airport into consideration. This bridge has the longest span in the world among continuous truss bridges.

-

C

Fiscal Year 2013

Shiodome Bridge Overpass on the Yaesu Route of the Tokyo Metropolitan Expressway [Reconstruction]

(Completed in 2014, Tokyo)

This bridge was rebuilt over a major intersection that has 50,000 vehicles/day in traffic volume. The bridge has an inner length of 93.5 m and an outer length of 101.1 m. To build the girder over the intersection, the main girder was assembled on the ground, then moved into the intersection on a multi-axel conveyor at night. A hoisting construction method using a gate-shaped gantry crane and PC cables was used to reduce the impact on traffic in the vicinity.

-

D

Fiscal Year 2015

Yokohama North (Loop) Line Bridge (Okumagawa Truss Bridge) [new construction]

(Completed in 2014, Kanagawa Prefecture)

This bridge is part of the Yokohama North (Loop) Line and spans the confluence point for three rivers―Tsurumigawa, Okumagawa, and Egawa. It is a simple double-deck truss bridge with a steel floor and is 158 m long. It boasts the longest span length in Japan for a bridge of this type.

The cantilever construction method was used to build the superstructure to preserve the area across the river and out of consideration for the wildlife living on the river embankments at the bridge site. Shimizu was responsible for the pile foundation for the bridge piers. -

E

Fiscal Year 2013

Kakamigahara Bridge [new construction]

(Completed in 2013, Gifu Prefecture)

This bridge is located on the Naka-Koami Line connecting Jogocho and Kawashima Koamimachi in Kakamigahara City. It is a 594-meter-long finback bridge with 10 continuous PC spans that span the Kiso River.

We used the P&Z construction method for the superstructure and achieved a substantial reduction in the construction period by building both the column heads and extending sections with the cantilever construction method at the same time. -

F

Fiscal Year 2010

Amarube Bridge [new construction]

(Completed in 2010, Hyogo Prefecture)

This is a 310-meter-long PC box girder extradosed bridge that has 5 continuous spans. It was built to replace the old Amarube Bridge and was designed to last 100 years.

We shortened the period of time during which train service was interrupted by using a construction method that involved moving a 3,820-ton girder horizontally and rotating it into place to connect with the existing railway line. -

G

Fiscal Year 2014

Ota River Bridge [new construction]

(Completed in 2014, Hiroshima Prefecture)

The Ota River Bridge is a mixed steel and concrete arch bridge that is 412 m long and has six continuous spans (with a maximum span length of 116 m). To build it, we use cantilever construction for the PC box girder, and used a floating crane to erect the complete arch structure mid-way. We then erected vertical arch supports to support the arch structure.

-

H

Fiscal Year 2012

Awa Shirasagi Bridge [new construction]

(Completed in 2012, Tokushima Prefecture)

The Awa Shirasagi Ohashi Bridge is a 1,291-meter-long bridge with a “cable egret” truss system. It is a road bridge that has a total length of 1,291 m, and it consists of two sections: A 4-span continuous “Cable Egret” plate girder bridge that is 575 m long, and a series of two 5-span continuous rigid-frame plate girder bridges that are 350 m and 366 m long, respectively. It is the world’s first bridge of the “Cable Egret” type and it was named this because the shape of the stretched cables resembles the snowy egret, which is the prefectural bird of Tokushima Prefecture.

-

I

Fiscal Year 2008

Yabegawa Bridge [new construction]

(Completed in 2009, Fukuoka Prefecture)

This is a PC cable-stayed bridge with three continuous spans. The center span is 261 m long, the longest in Japan among cable-stayed bridges. For the bridge foundation, we used the pneumatic caisson construction method to drill down 49.5 m, the deepest drilling depth in Japan.

* Click here to access the details.

Shimizu will continue to hone its development of bridge technology in the future. We will strive to provide value that exceeds the expectations of our customers and society, and will contribute to establishment of social infrastructure.

Onahama Marine Bridge (Fukushima Prefecture)

The information posted here is the current information on June 26, 2018.

Please be aware that this information may have changed by the time you view it.