Building Lives and Protecting CommunitiesGINZA KABUKIZA (Kabuki theater),

the fusion of traditional skills and advanced technology

Lighting design: Motoko Ishii, Akari-Lisa Ishii, and Motoko Ishii Lighting Design

(Photo: Grand opening of new building in 2013)

Giving the Kabukiza a New Lease on Life for the Next 100 Years

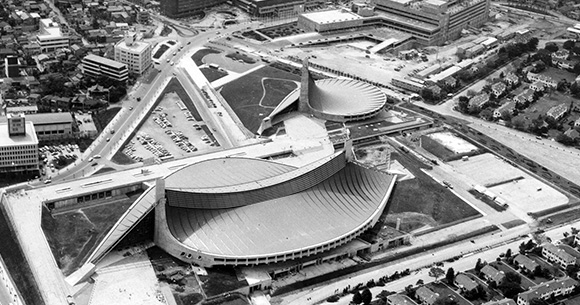

The Ginza district in Tokyo, an area that conveys both good old culture and the latest trends. The Kabukiza, which has continued to pass down the traditional art of Japan for more than 120 years, was reborn in a new form in February 2013. GINZA KABUKIZA is a multipurpose complex consisting of a Kabuki theater in the traditional architectural form and a high-rise office building. It has four floors below ground, and 29 floors above ground. The building is a fusion of time-honored traditional techniques and the latest advanced technology and was a very special project to Shimizu.

More than 60 years Since We Built the Kabukiza

The Kabukiza, which was closed for reconstruction at the end of April in 2010, was the fourth generation of the building since it first opened in the Meiji period (1868-1912). It was later designated as a registered tangible cultural property, and Shimizu’s involvement with the Kabukiza began with work on this fourth-generation building. Shimizu gathered the best of traditional architectural techniques from all over Japan to build it at that time. We employed an artistic design in keeping with the atmosphere of a theater and the opulent world view of Kabuki. Since then, we have been involved in countless additions and renovations. The fifth-generation GINZA KABUKIZA project was also handled by marshalling all of the technical capabilities of Shimizu.

Replicating the External Appearance of the Previous Kabukiza with BIM and a Full-Scale Drawing

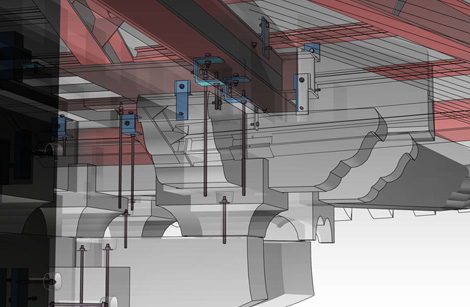

The major mission we were tasked with in building the lower section where the theater would be located was to replicate the image of the fourth-generation Kabukiza unchanged. The design of the fourth-generation building, which was built with steel-reinforced concrete, was reproduced with the latest steel frame, without changing the visual impression. That difficult problem was solved with BIM (Building Information Modeling) to produce a three-dimensional building model on the computer and the “full-scale drawing” expertise of the head carpenter.

Utilizing the Wisdom of the Traditional Master Carpenters Today

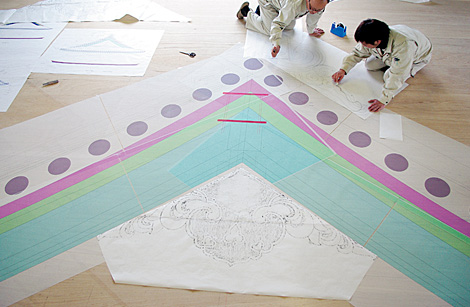

In construction of a Kabukiza, for example, the roof camber and decorative wooden supports under the eaves serve as structural supports for the roof. BIM therefore demonstrated its great strength in verifying the functions of these as structural components, as did the full-scale drawing in adjusting the appearance as a decorative component. Use of a full-scale drawing makes the finer details that would not be visible on a regular drawing, such as the warping of a curved surface, immediately apparent. Shimizu’s expertise in the traditional techniques of Japan that have been cultivated since the company was founded proved to be a major strength.

BIM and a full-scale drawing were used to achieve the exact details of the roof eave camber and the decorative wooden supports under the eaves.

Interior Appearance and Sound Were Also Faithfully Replicated

The build of the Japanese cypress-wood stage that is a main attraction inside the theater is also one highlight in replicating the feel of the old Kabukiza. Approximately 1,200 100-year-old Japanese cypress trees from a single mountain in Tanzawa, Kanagawa Prefecture were procured to keep the color of the floor beautiful and even. We were also passionately devoted to reproducing sound that would provide a listening experience unchanged from the fourth-generation building. Immediately after beginning construction, a 1:10 scale model of the actual theater was created. Eight sound sources and 60 measuring points were set up, and painstaking verification was repeated a number of times to create the same acoustic field.

The patterning on the wall material was faithfully reproduced.

Taking on the Challenges of a Short Construction Period and Exacting Precision

The short construction period was a major issue that affected the entire project, right along with accurately replicating the feel of the old kabuki theater.

Integrated construction of a theater and high-rise office building sounds simple, but required monozukuri (superb craftsmanship) on a broad range of aspects. Such details included the largest revolving stage in Japan, an expansive underground open space 1,300 m2 in size, a roof-top garden on the fifth floor, and office floors equipped with the latest advanced functions. Building the Ginza Kabukiza, with its complex combinations of such spaces, in the 29-month construction period amid interruptions in the supply of key materials due to the Great East Japan Earthquake and the major flooding in Thailand presented a challenge of the tallest order.

Simultaneous Construction Below and Above Ground: Impeccable Process Management Achieved by Modularizing the Framework and Finishing

The keys to overcoming the tight schedule were employment of the inverted construction method and impeccable process management achieved through modularization of the framework and finishing. The inverted construction method was used to build below ground and above ground safely and simultaneously, while increasing work efficiency and precision through modularization of the framework and finishing. The synergies achieved from the two methods dramatically sped up construction. Each and every person at the work site was determined to complete the work no matter what, and the work proceeded at the ultra-rapid pace of building one floor of the high-rise office building in six days. The challenge, which commanded all of Shimizu’s technical capabilities, finally culminated in completion of the new landmark in the Ginza district by always racing against time and coordinating details down to the millimeter.

The Exchange Between the Good Old and the New Creates the Future.

“It is exactly the same as the old Kabukiza.”

Those words, uttered on the day construction was completed by the president of SHOCHIKU Co., Ltd., the company that ordered the construction, were the best praise we have ever heard.

The Ginza Kabukiza, incorporating multiple new functions as a cultural and business venue while faithfully passing down the tradition. It enables people from Japan and overseas to gather with many different purposes, beginning exchanges never before possible.

Column

Doubles as a disaster mitigation support facility that can accommodate 3,000 people during a disaster

An emergency warehouse of emergency supplies has been established in the Kobikicho Square (1,300 m2), which connects directly to the Tokyo Metro Higashi-ginza Station. Plans call for the intake of 3,000 people who cannot return home in the theater seats and Kobikicho Square in the event of a disaster. It is provisioned with a three-day supply of food.

The information posted here is the current information on September 1, 2017.

Please be aware that this information may have changed by the time you view it.