Temple and Shrine ConstructionHeisei Shrine Renewal at Izumo Taisha for the Next Generation

Izumo Taisha, or Izumo Grand Shrine, is well known as the home of the god for matchmaking.

Its construction was also recorded in the Kojiki, the oldest written history of Japan, and it is an ancient shrine that represents Japan.

The Heisei shrine renewal of that Izumo Grand Shrine was completed in 2013, for the first time in 60 years.

The honor of taking on the challenge of this highly important project was bestowed upon Shimizu, which has its roots in the temple and shrine carpenters.

The Technology of Shrine and Temple Construction Carefully Protected and Passed Down

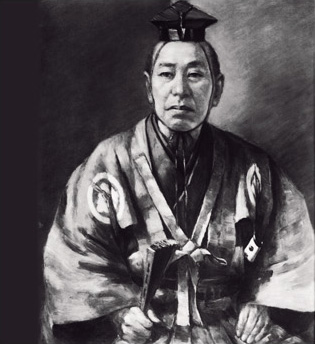

Founded in 1804 in Kanda Kaji-cho, Edo (present-day Tokyo), Shimizu has a history that spans more than 210 years.The founder, Kisuke Shimizu I, displayed his skills in the complete renovation of Nikko Toshogu Shrine, and the complete rebuilding of the West Wing of Edo Castle, and many other traditional types of architecture, and his carpentry skills and spirit were protected and passed down to the present day, through the numerous shrines and temples that Shimizu has built. Shimizu's expertise in building shrines and temples led us to take on the great challenge of the Heisei shrine renewal.

Extensive Experience and Expertise

The last shrine renewal occurred 60 years ago. Neither accurate records nor recollections still exist, due in part to the change in generations. The fact that we could not determine the full extent of the work until we had tried dismantling the shrine spoke of the difficulty involved in preservation and repair. Without our expert knowledge and extensive experience, we would not have been able to complete the task. This was precisely the reason why Shimizu was chosen for this monumental project.

Touching the Work of Our Predecessors through Preservation and Repair

Although it is called shrine renewal, it does not entail dismantling the old building and building a new one from scratch. The general principle in the preservation and repair of historical cultural treasures is to religiously adhere to the way things were previously done. We dismantled the shrine with great care, investigating the materials and dimensions, and recording everything as we worked to leave a record for the next generation. In other words, the work involved receiving and passing on the intent of the craftsmen who worked on the previous shrine renewal.

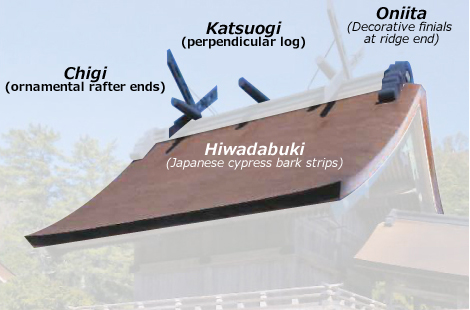

The Secrets of the Great Roof that Protected Izumo Taisha from the Wind and Rain for Decades

The first step in the repair of Izumo Taisha was to cover the main shrine with a covering roof called a "suyane" (temporary roof), take down the "oniita" (finials) at the ends of the roof ridge, the "chigi" (ornamental rafter ends), and the "katsuogi" (log on the rooftop set perpendicular to the ridgepole) which decorated the rooftop, and begin dismantling the "hiwadabuki" (strips of Japanese cypress tree bark). Roofs thatched with hiwadabuki are generally thatched in segments measuring approximately 75 cm in length. In the case of Izumo Taisha, however, long Japanese cypress bark strips measuring approximately 120 cm, approximately 105 cm and approximately 90 cm in length were used. The durability was improved by making the "fukiatsu" (bark thickness) thicker, an ingenious way to extend the life of the rooftop. It was perhaps due to that, that the roof foundation was in better shape than we expected.

The Spirit of Our Predecessors Lingered in the Perfect Work

A three-layer plank roof was laid beneath the hiwadabuki, and kokuso, a lacquer-based mixture was packed into the gaps between the planks. This mixture served the dual purpose of gluing the planks together and preventing water seepage. Even one drop of rain was not permitted to fall on the shrine the god lives in. This gave us a peek into the spirits of our predecessors whose ingenious inventions were used to build the roof.

So People Who Work on the Shrine Next Will Say, "The Work Done on the Heisei Shrine Renewal was Impressive"

A massive number of bark strips, approximately 640,000 in total on the roof of the main shrine, were disentangled by hand and peeled off, one by one, after which the roof was rethatched. In a word, the sheer scale and the detailed finishing of the roof achieved through careful handwork was a masterpiece. When the shrine is renewed again sixty years from now, we want people to say, "the work done on the Heisei shrine renewal was impressive."

If you look at the beautifully rethatched roof, it is clear to that there is no deceit in that thought.

The Difficulty of Passing Down Traditions

The oniita (finials), katsuogi (perpendicular log), chigi (ornamental rafter ends), and other decorative elements were simultaneously restored as the roof was rethatched. A now rarely used technique called "chan-nuri" was used to relacquer these. In accordance with the general principle of using the old techniques, we tracked down the fact that the main ingredient was perilla oil through advance research, but we did not know what else the lacquer contained and what the proportions of the ingredients in the mixture were. Shimizu spent about two years trying many different combinations. As the deadline was fast approaching, we finally found the main ingredients of the lacquer in the archives. It also recorded some of the additional ingredients in the mixture, and we succeeded in reproducing it.

We will pass on what we have received from our predecessors. While this is simple to put into words, implementing it required countless attempts through trial and error.

Shimizu Wants to Always Remain a General Contractor that is Strong in Shrine and Temple Construction

We succeeded in completing the Heisei shrine renewal through the combined skills of everyone involved in the construction, with each doing his or her best work in his or her area of specialization.

It was the pride as a person involved in the monozukuri (superb craftsmanship) of doing work that you can boast of to the next generation that united the hearts of all who took on the challenge of this great project. That is also the mark of the corporate slogan that Shimizu operates by: "Today's work, Tomorrow's Heritage."

Work that we can be proud of in 60 years.

The Heisei shrine renewal is truly an expression of Shimizu's philosophy.

Column

The God of Matchmaking Smiled at Our Professional Spirit

The roof covering the steps to the main shrine is called the "hashi kakushi." During the dismantling, a break was found in the decorative ridgepole on this roof, and the entire roof had to be restored. However, the domestic pine trees that provide the raw material had been devastated by an infestation of pine weevils. The only place they could be procured from was the Tohoku area, so we decided to have them shipped from a lumber yard in Ofunato, in Iwate Prefecture. Then the Great East Japan Earthquake occurred three days before the delivery date. We could not get in contact with the lumber yard for about two weeks, and thought that we would have to extend the construction term.

The damage to the lumber yard was minor and the promised pine wood arrived without incident, on March 31, perhaps it was because the prayers of those involved were answered.

This was due to the spirit of everyone at the lumber yard, who each resolved to accomplish his mission, regardless of the circumstances. That strong resolve moved the god of matchmaking, and he cemented a relationship between those involved with the materials and the construction. Everyone was able to feel a special sort of power.

Traditional "Chonahajime-shiki" (Start of Carpentry Work Ceremony) of Temple and Shrine Craftsmen Handed Down to Shimizu

The chonahajime-shiki is a ceremony performed before master craftsmen and others involved in construction begin work. Participants don costumes from the ancient ritual and use ceremonial carpentry tools to seek divine protection so that the construction work will be completed swiftly and safely.

The only companies that still perform the chonahajime-shiki at the beginning of the year are Kongo Gumi Co., Ltd., known as the world's oldest existing company, and Shimizu Corporation.

The information posted here is the current information on September 1, 2017.

Please be aware that this information may have changed by the time you view it.