Dreaming of New Energy Shaping the Future of Large Onshore Wind Turbines

Onshore wind power generation produces electricity by harnessing the wind’s power day and night. As the demand for renewable energy grows, demand for wind power is expected to accelerate even more. Large wind turbines with high efficiency are expected to hit the market. In response to the growing size of wind turbines, Shimizu has developed Japan’s largest tower crane for onshore wind turbine construction.

Japan’s Largest and Highest Performance Crane for Efficient Construction

The S-Movable Towercrane (SMTC) is a mobile tower crane developed by Shimizu, designed to support the construction of large onshore wind turbines.

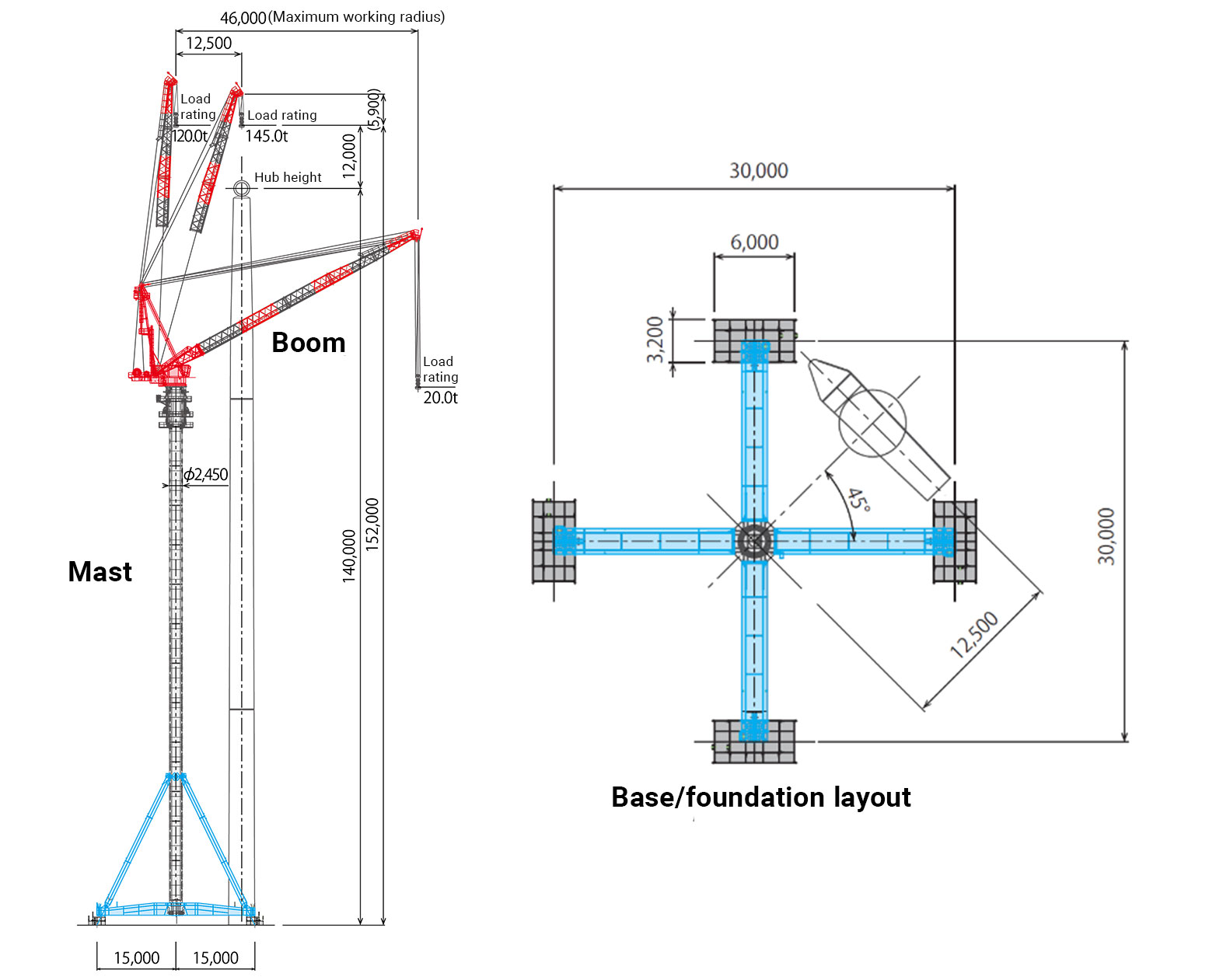

With a maximum working height of 152 meters and a maximum lifting capacity of 145 tons, it boasts the largest size and highest performance among self-supporting tower cranes in Japan. This crane can efficiently construct sizeable onshore wind turbines in the 6-7 MW range.

It was completed in 2023. After undergoing various tests, it was used in 2024 for the southern section of the Ashikawa Wind Farm (WF) (Hokkaido), one of Japan’s largest onshore wind power projects. The construction of a 4.3 MW wind turbine has been completed.

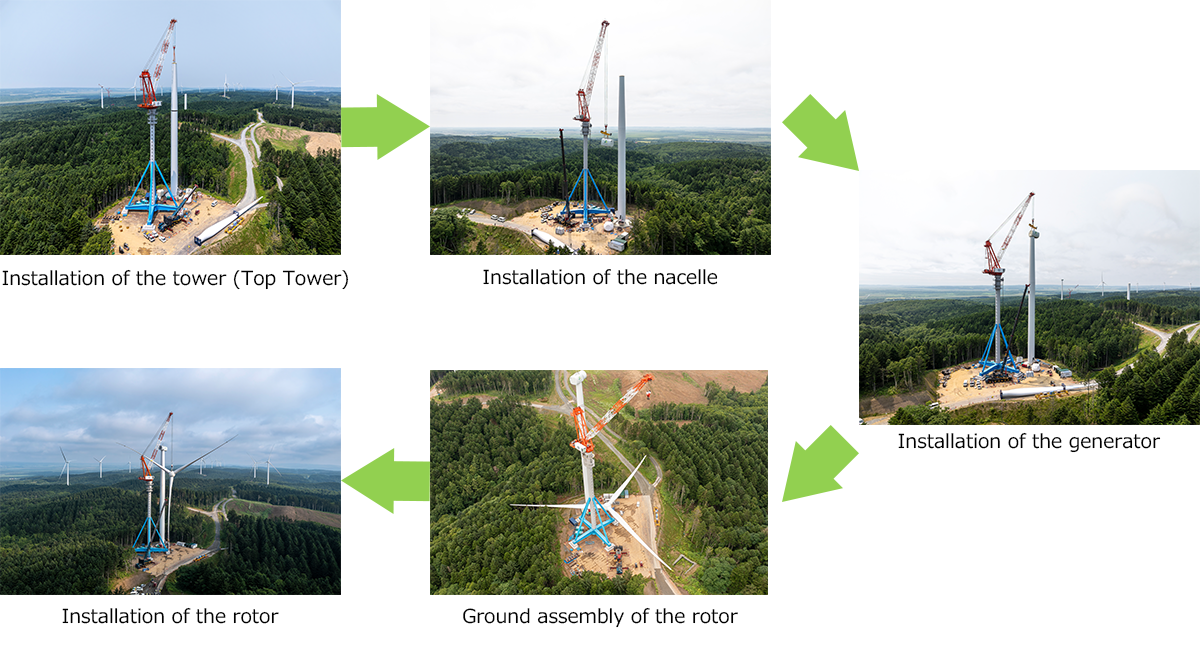

The wind turbine has a tower height of 85.0 meters, a blade length of 60 meters, and a maximum blade tip height of 145 meters. For the construction of the first wind turbine, we completed the entire process in four days, from unloading the materials and erecting the tower to pre-assembling the blades and rotor on the ground, and then lifting and assembling the rotor with the blades attached. The work demonstrated the anticipated construction efficiency.

| Maximum working height | 152 meters |

|---|---|

| Maximum lifting capacity | 145 tons |

Trademark registration details S-Movable Towercrane [Registration Number]Trademark Registration No. 6441546 (T6441546)

Main specifications of SMTC

Construction progress with SMTC

Overview of the southern section of Ashikawa Wind Farm (WF)

- Location

- Toyotomi Town, Teshio District, Hokkaido

- Client

- Dohoku Wind Farm LLC

- Construction period

- April 2020 - July 2025

- Design and construction

- Shimizu Corporation

- Project description

- 4.3 MW wind turbines x 15, interconnection substation, and internal power line construction

Development Background

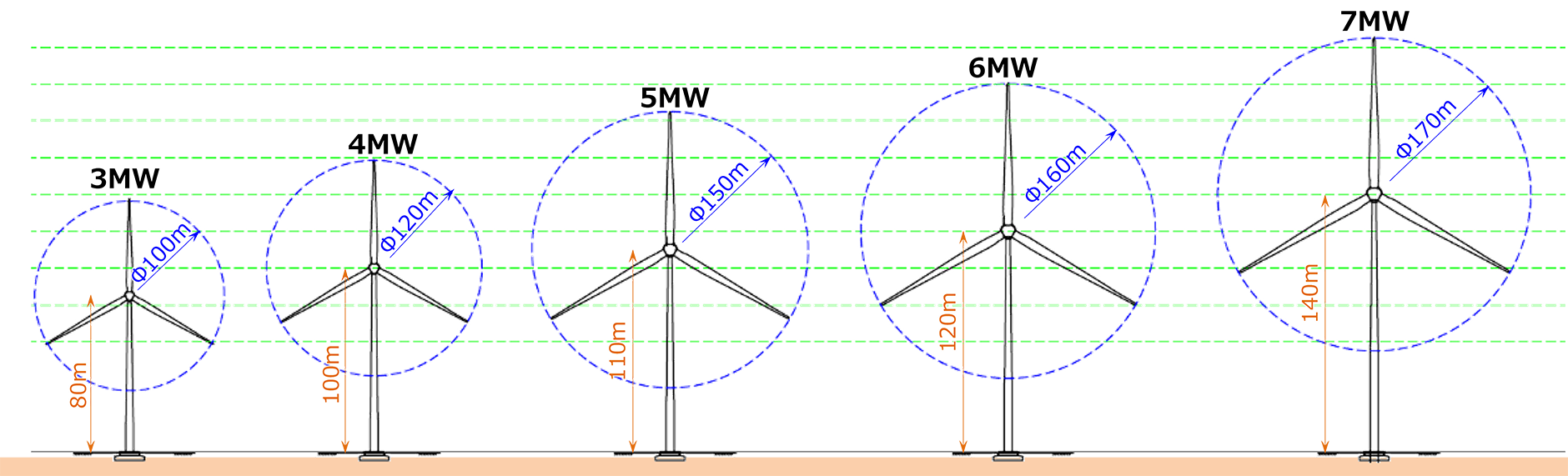

Since Japan’s declaration of carbon neutrality in 2020, the country has begun taking steps to achieve net zero CO2 emissions by 2050. At the same time, the feed-in tariff for onshore wind power has been steadily decreasing. The industry is moving towards larger, more efficient wind turbines to improve economic viability.

Scaling up wind turbines allows stable operation at higher altitudes where stronger winds prevail, leading to increased power generation. Based on this, the market introduction of large wind turbines in the 6-7 MW class is expected. Additionally, as older wind turbines reach the end of their service life, a growing demand for replacements is expected, with the market size for onshore wind power facilities projected to exceed 5 trillion yen by 2030.

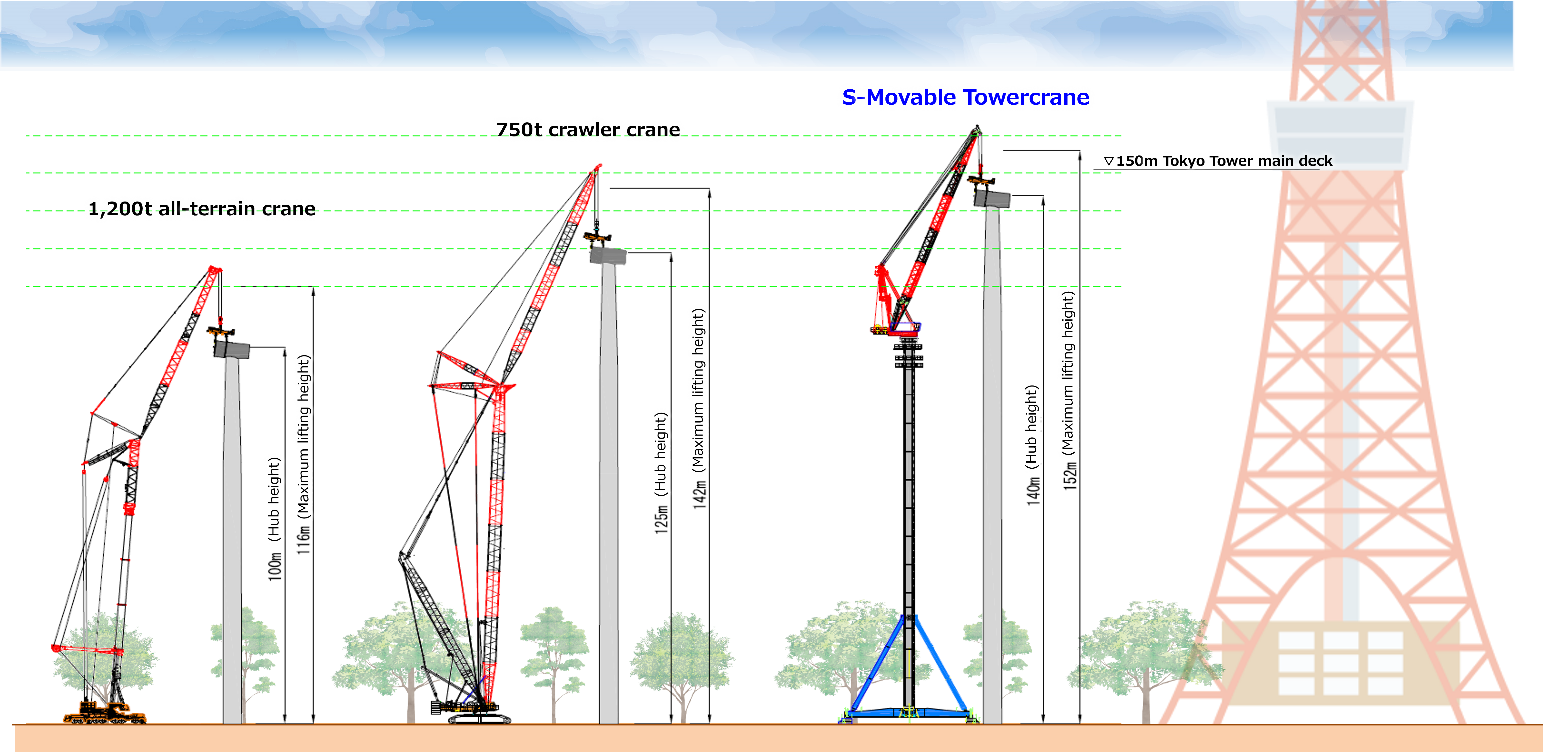

However, the cranes currently used for onshore wind turbine construction can only handle turbines with a tower height of up to 100 m and a 4 MW class. Furthermore, the 1200t all-terrain crane, which is the main crane used in wind turbine assembly, is limited to just 16 units in Japan, and no additional units are expected to be produced. While using a 750t crawler crane is an option, it requires clearing a large area of trees for the assembly and disassembly of the crane boom, making it challenging to obtain the necessary permits in Japan.

To address this issue, we have developed the SMTC crane, which is ideal for constructing large onshore wind turbines.

Improvements to Enhance Construction Efficiency

Status of the SMTC multi-axle trailer mobility test

Reducing Cycle Time through Movement with a Multi-Axle Trailer [Patent Registered]

The SMTC not only offers the largest and highest performance in Japan, but it also provides a significant advantage in quickly moving between wind turbine construction sites, which is crucial for developing onshore wind power facilities.

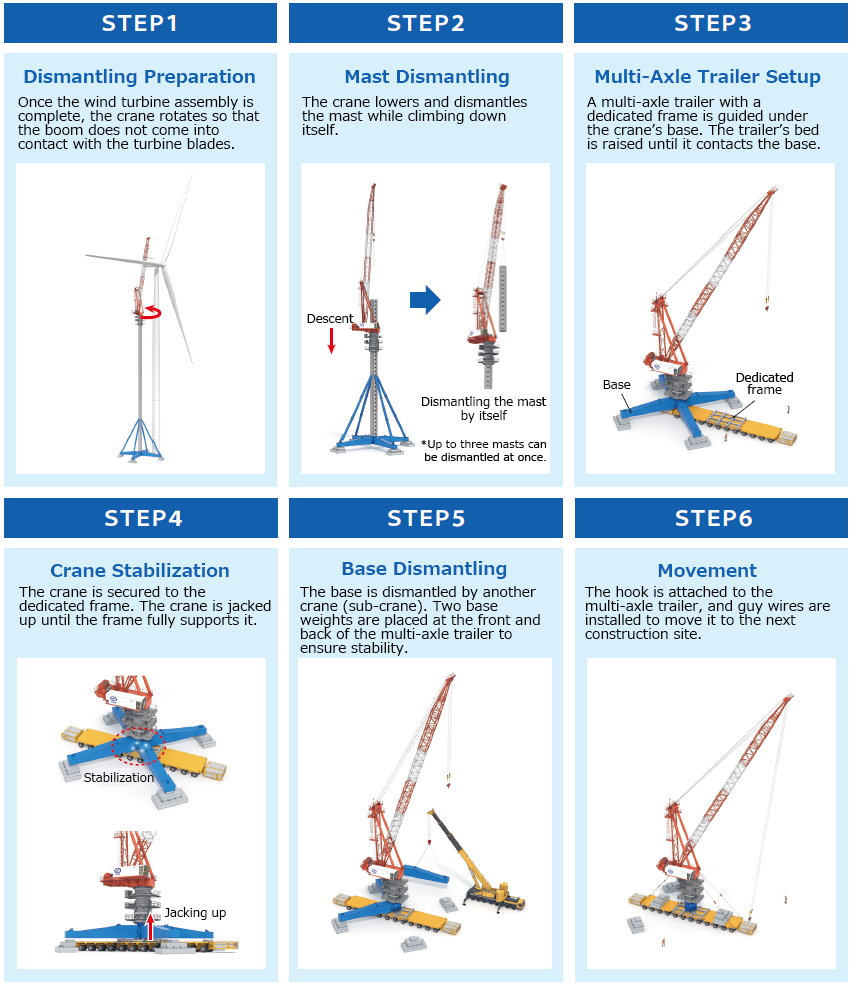

After the wind turbine is constructed, the crane dismantles the mast while climbing down itself. The crane itself is not dismantled; instead, it is placed on a self-propelled multi-axle trailer and moved to the next wind turbine construction site. The entire cycle, from dismantling to relocation and reassembly, is completed in five days.

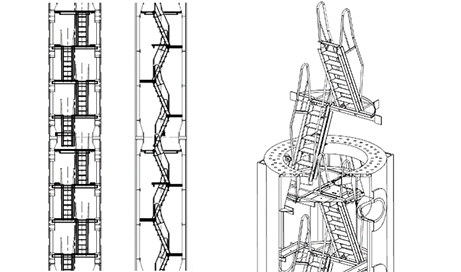

Adoption of a Cylindrical Mast for Wind Deflection

The SMTC features a cylindrical mast. The wind force coefficient of the cylindrical shape is 0.7, which reduces wind pressure compared to the traditional rectangular truss shape with a coefficient of 1.6. By minimizing the load on the crane from the wind, mast deformation and swaying are reduced, ensuring stable construction.

While ladders are typically used for vertical access inside the mast, stairs have been installed to ease the operator’s burden.

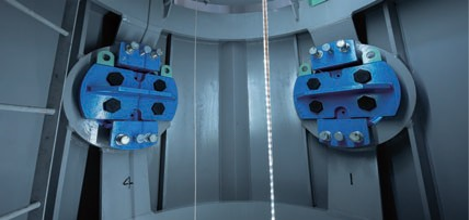

Pin-Coupled Mast Stay [Patent Pending]

Installing the mast stay reduces mast deformation during lifting operations and in strong winds, enhancing stability and safety. To shorten the time required for assembly and disassembly, a pin structure was implemented at the connection point between the mast and the mast stay. Typically, securing the mast stay during assembly or disassembly would require external high-altitude work, increasing risks. However, with the SMTC, the mast stay can be safely secured from the inside.

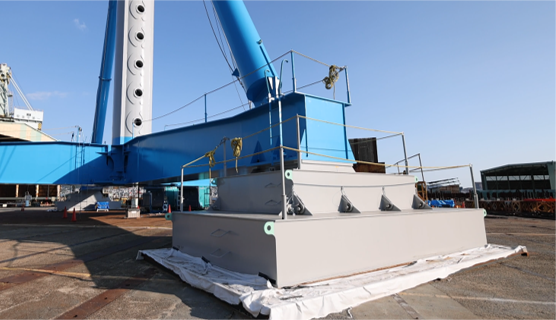

Counterweight for Crane Inspections

Tower cranes may need crane inspections by the Labor Standards Inspection Office each time a wind turbine is assembled. The test duration can be reduced by using the crane’s own counterweight for the load testing during the inspection.

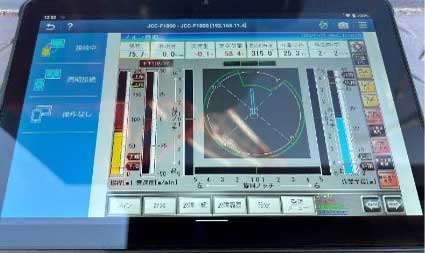

Remote Operation

Remote operation is available, allowing the operator to control the crane while monitoring tasks like rigging, hoisting a grounded load, and bolt connections during wind turbine assembly, without needing to ascend to the operator’s cabin. Although the crane is primarily operated from the cabin, priority is given to the previously started control device, restricting simultaneous operation and ensuring safe use.

Contributing to the Growth of Both Onshore and Offshore Wind Power

To achieve carbon neutrality by 2050, the demand for onshore wind turbines, which are a key source of renewable energy, is expected to increase significantly. According to the Japan Wind Power Association (JWPA) and the Ministry of Economy, Trade and Industry, the installed capacity of onshore wind power as of December 2023 is around 5 GW, with installation targets for 2030, 2040, and 2050 set at 18 GW, 35 GW, and 40 GW, respectively.

Shimizu has already constructed nearly 450 onshore wind turbines in Japan. Based on available data, Shimizu’s market share reached about 20% by the end of December 2023.

Equipped with the largest domestic mobile tower crane for onshore wind power, the SMTC, and the world’s highest-performing self-propelled SEP vessel for offshore wind power, the BLUE WIND, Shimizu is a leader in wind power facility construction and will continue to contribute to the growth of renewable energy.

The information posted here is the current information on April 3, 2025.

Please be aware that this information may have changed by the time you view it.