Shimizu works to improve health and safety management and engages in activities to prevent occupational accidents, harm to health, and protect the environment at job sites.

Basic Health and Safety Policy

Basic Principles

Shimizu stands on the principle of respect for human life and human beings and places the highest priority on safeguarding the lives and health of our employees in all corporate activities. We have established a corporate culture that is grounded in safety and maintain a safe, comfortable work environment.

Measures for Achieving Our Goal

- Shimizu operates a Construction Occupational Health and Safety Management System (COHSMS). We pursue enhancement of preventative safety measures through risk assessment and strive to reduce occupational accidents on a continual basis.

- We recognize the importance of both safety and production in business activities, based on our policy of safety as a top priority. We ensure safe equipment by implementing redundant safety measures and other means and work to make construction procedures readily visible, from the construction planning stage onward.

- We encourage suppliers and subcontractors to establish independent safety management*, actively encourage disaster prevention conferences, and clarify the respective role and responsibilities of Shimizu and our subcontractors in promoting the prevention of accidents.

- We recognize our responsibility as a business operator to further improve initial explanation of projects and training on job site rules to workers who are new to a job site. We work to ensure strict safety compliance among workers and eliminate accidents involving them.

- We make sure that managers in charge of health and safety have the knowledge and dynamism to educate employees and develop them as promoters of compliance with laws and regulations (strict compliance with company rules for safety work) and accident prevention.

- We have strengthened rules on working safely to eliminate exposure to dust, asbestos, and other materials that are harmful to health, and work to provide comprehensive education on preventing health hazards.

The policies above also apply to subcontractors to which construction work is outsourced.

Shimizu distributes the Supplier and Subcontractor Health & Safety Management Guidelines to subcontractors we outsource construction work to and facilitates independent and sustainable health and safety management by these companies.

Company-wide Health and Safety Plan for Fiscal 2025

"Raise Individual Safety Awareness—Achieve Zero Accidents through Teamwork"

Code of Conduct for Achieving Zero Accidents

All personnel involved at worksites must share a sense of ownership, and with a conviction to protect the lives and physical and mental well-being of oneself and colleagues, practice smooth communication and implement the PDCA cycle.

Departments, worksites, project leaders, and foremen are expected to help each worker strengthen their awareness of potential hazards and promote safety activities that encourage every team member to see safety as their own responsibility.

PDCA Cycle

P (Plan): Identify potential accidents and disasters based on risk assessment and proactively ensure safety by incorporating "double safety" measures into work plans and procedures.

D (Do): Share awareness of accident and disaster risks; employees, foremen, Safety and Health Supervisors, and work supervisors must fulfill their responsibilities and ensure safety through teamwork.

C (Check): Based on the new "Three Actuals" principle (Actual Site, Actual Thing and Actual Situation) with increased verification eyes, conduct site patrols and inspections to confirm safe conditions.

A (Act): If actual operations deviate from the plan, stop the work, reassess the risks, revise the plan, and communicate the changes to all stakeholders before resuming.

Key measures

- Eliminate fall and drop-related accidents (refer to fall protection equipment as safety belt)

- Eliminate construction machinery and crane-related accidents

- Eliminate collapse-related accidents

- Eliminate public accidents, infrastructure damage, and fire incidents

Operating System (Responsibility and Management Resources)

Health & Safety Management Structure

Every month, each business branch holds a Branch Health & Safety Committee meeting, where labor and management representatives discuss and report on progress related to health and safety activities. Important decisions made in the Committee meetings are communicated to all employees mainly through the company Intranet. Shimizu also has a Company-wide Health and Safety Committee that oversees the Branch Health & Safety Committee, as well as manages health and safety and deliberates at a high level on health and safety issues such as employee health management. This Committee is chaired by either the president, executive vice president, or head of the Safety Administration & Environment Division, with representatives from labor and management serving as committee members.

Health & Safety Management Structure

Health & Safety Management Structure for Construction Projects

The Health & Safety management structure for construction projects(Executive Vice President and Representative Director) is headed by a safety & environmental officer, who is director and senior managing executive officer appointed by the president. The health & environmental officer is responsible for overseeing the company’s health and safety management. The head of the Safety Administration & Environment Division plans and implements specific activities and initiatives. At the branch level, each branch manager is responsible for planning and implementation in their own branch. Shimizu also holds an annual Safety Committee meeting, where committee members including the safety & environmental officer report on the status of health and safety activities. The committee also deliberates and makes decisions on key issues concerning health and safety plans such as preventative measures for serious accidents and disasters.

Initiatives to prevent occupational accidents

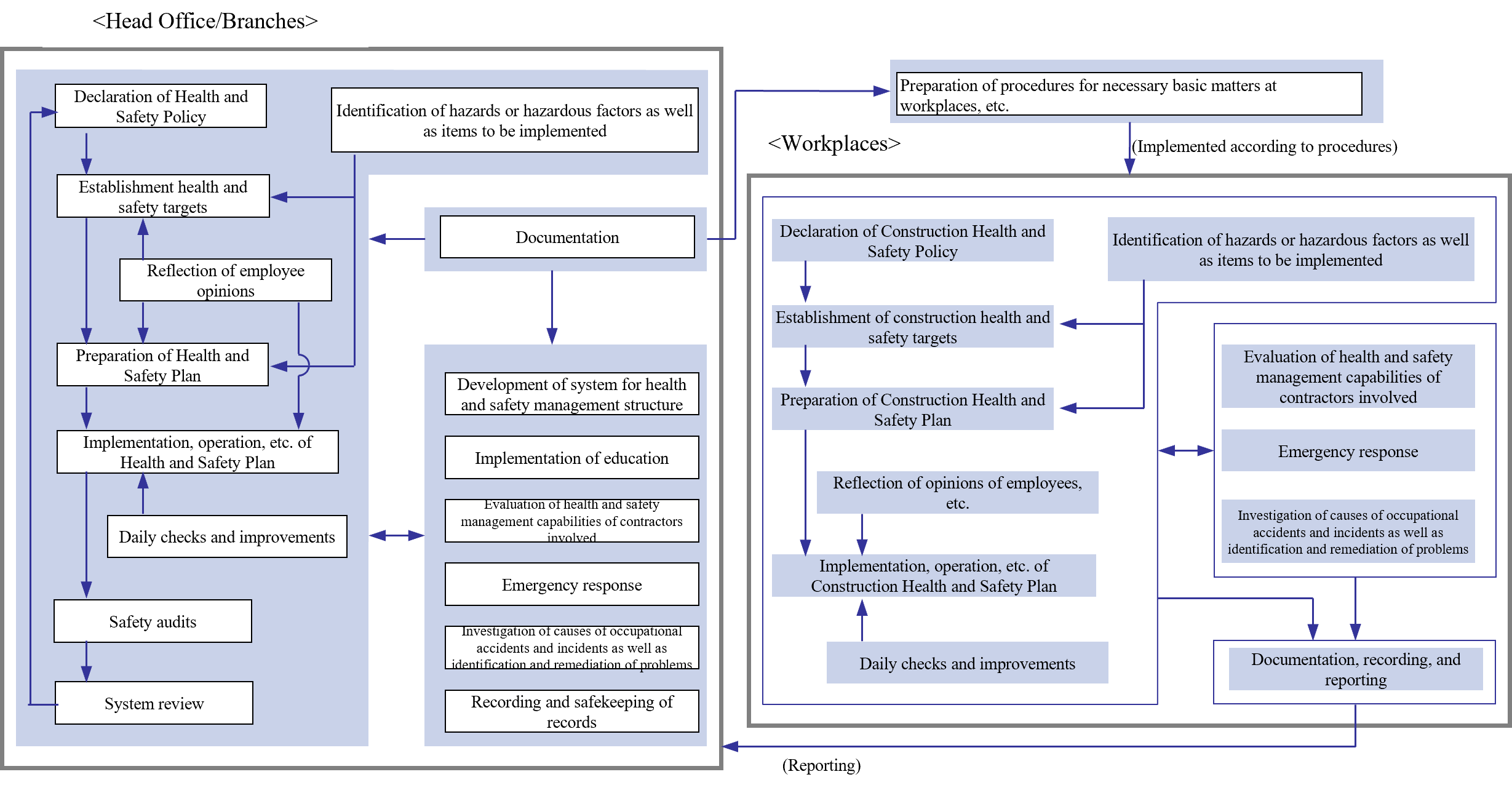

Construction Occupational Health and Safety Management System

Our safety management method is to promote measures to prevent accidents by taking preventive safety measures that focus on universal potential hazardous factors.

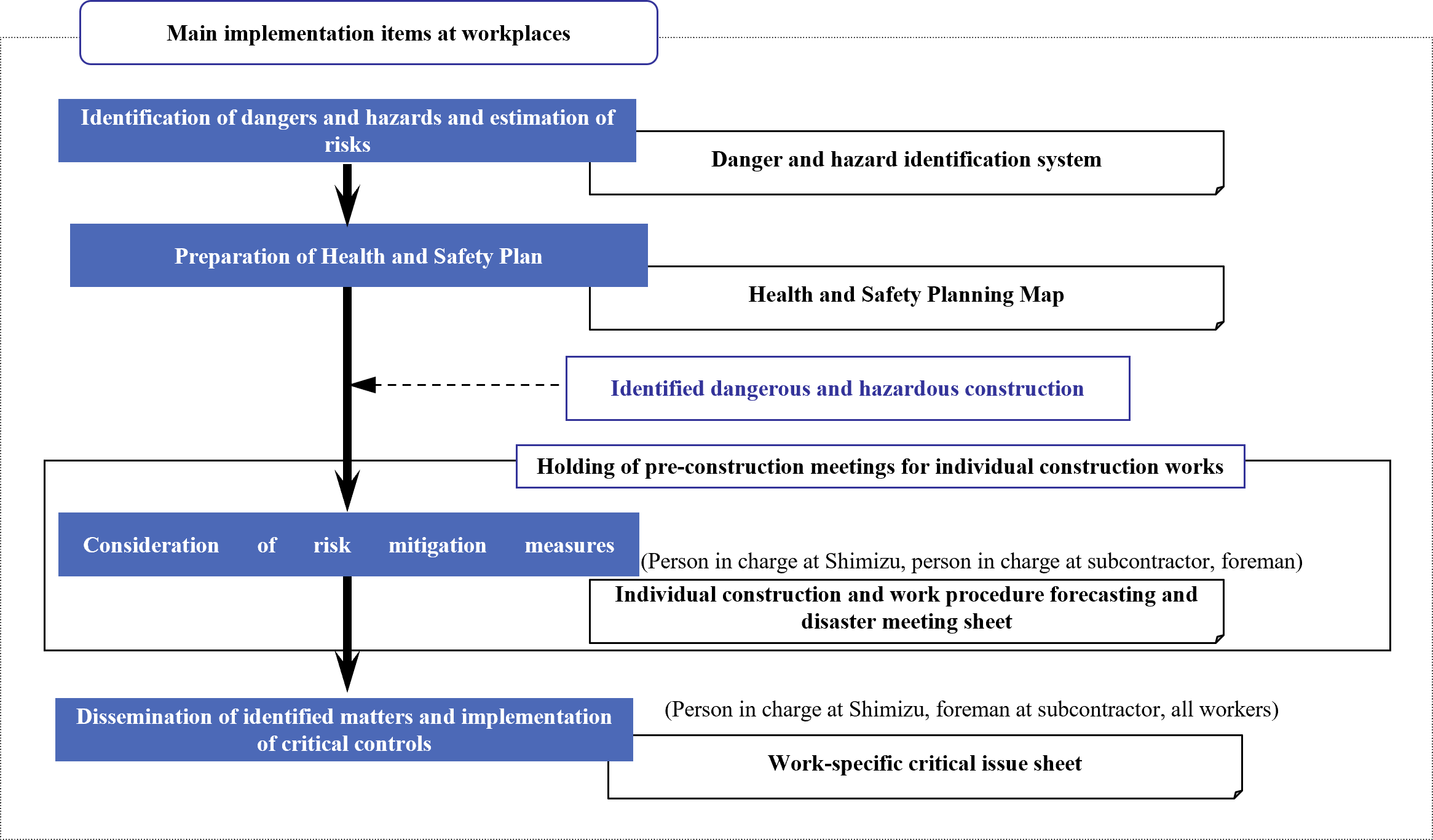

At all work sites, applicable hazardous work is identified at the pre-construction review meeting before the start of construction. After the start of construction, we conduct risk assessments for each work procedure at individual pre-construction meetings and assign a person in charge to implement risk mitigation measures.

Since 2001, we have been operating an occupational health and safety management system based on Construction Occupational Health and Safety Management System (COHSMS) Guidelines to raise the level of our health and safety standards by effectively implementing the PDCA cycle.

COHSMS(PDF:293KB)

The Nagoya branch acquired certification ahead other branches.

Overview

Flow of Implementation at Workplaces

Sharing Information and Activities to Prevent Recurrence

At the job site, we and our suppliers and subcontractors work together on a regular basis to perform basic and routine safety management tasks as part of a safe construction cycle. We implement a safe construction cycle to facilitate information sharing such as coordination between work areas and prevent accidents from occurring.

| Daily Work Cycle | Weekly Cycle | Monthly Cycle | |||

|---|---|---|---|---|---|

| When | What | When | What | When | What |

| Before beginning |

|

Weekdays |

|

Designated day |

|

| During work |

|

Day Before a Holiday |

|

||

| After work is completed |

|

||||

Safety Patrols by President

Every year during National Safety Week and National Occupational Health Week, the president and group-wide safety committee members conduct on-site safety patrols to check construction progress of construction and safety measures at work sites. In addition to observing work procedures and basic rules, they remind workers of the need for thorough heat stroke prevention measures.

In fiscal 2023, they toured construction sites for architectural and civil engineering projects in Tokyo under the jurisdiction of the Tokyo Branch.

Health & Safety Results

Health & Safety Results

The LTI (lost time injury) Frequency Rate* for FY2024 was 0.76, a 0.22 deteriorate from FY2023.

LTI (lost time injury) frequency rate: The number of deaths and injuries per million cumulative man-hours. Figures for all industries and for the construction industry represent accidents resulting in one or more lost work days, calculated on a calendar-year basis. Figures for Shimizu represent accidents resulting in four or more lost workdays, calculated on a fiscal-year basis.

Accident Analysis

The following procedures are followed when responding to on-the-job accidents:

- Provide information to the relevant people through the accident reporting system.

- Perform an investigation of the accident and include safety staff in the investigation.

- Formulate plans for and implement corrective measures to prevent recurrence of similar accidents based on the investigation and analysis.

- Roll out measures internally, across the organization when necessary.

- Accumulate accident data for use of risk assessments, etc. and prepare safety-related statistics.

By accident type, the most common was slip, followed by fall and drop.

There were 55 incidents in FY2024 that resulted in four or more days of absence from work, up by 10 from the previous year.

Falls remain one of the most frequent causes of accidents, often stemming from insufficient coordination between our company and subcontractors. To prevent such incidents, we identify fall-risk tasks each day, and our employees are required to visit the site before work begins to discuss potential hazards directly with those involved. These efforts are part of our ongoing commitment to ensuring safer on-site operations.

Based on analysis results and severity of accidents in FY2024, we will continue to prioritize eliminating fall and drop-related accidents in FY2025, while also focusing on the elimination of construction machinery and crane-related accidents, collapse-related accidents, and public accidents, infrastructure damage, and fire incidents, aiming for further reduction in accidents.

Ensuring safety is fundamental to construction and manufacturing, and it forms the basis of client and public trust. By working together—our company, subcontractors, foremen, and workers—we aim to fulfill our roles and responsibilities and achieve zero fatal, severe, and public accidents.

Mechanism for Handling Complaints

The link for complaints regarding health and safety is listed below.

Health & Safety at Suppliers and Subcontractors

Training Support for Suppliers and Subcontractors

With regards to the health and safety trainings listed below, Shimizu provides support and guidance to its business partners such as by supplying training material, lending venues, and dispatching instructors.

- Safety training for workers upon initial employment, upon initial dispatch to a job site, and upon changes made to their assigned work

- Special training for workers assigned to work legally designated as dangerous or hazardous

- Training for foremen and safety and health officers

- Training for workers assigned to dangerous and hazardous work and capacity building training for workers assigned to health and safety operations

- Shimizu also cooperates to provide training opportunities for workers regarding crane operation, gas welding, and other technical skills.

Kamewarigo Mobile Safety Dojo (Training Room)

In the aim of strengthening and enhancing safety education for skilled construction workers, we developed a safety experience vehicle called “Kamewarigo” equipped with hands-on safety education tools. It is now operational.

As a part of the training program at Shimizu Takumi Training Center, our education and training facility for skilled workers, we provide hands-on safety education utilizing Kamewarigo, primarily directed at skilled workers at our job sites. We also do on-site classes all over the country.

Strengthening Partnership with Suppliers and Subcontractors

There are two multi stakeholder initiatives that aim to enhance our cooperation with suppliers and subcontractors to ensure quality and safety: 1. The Shimizu Rengo Kanekikai (hereafter, “Kanekikai”). 2. The Shimizu Construction Accident Prevention Council.

The Kanekikai independently engages in activities aiming to achieving the following: talent development for skilled workers, productivity improvement, cost reduction, and elimination of occupational accidents.

Shimizu also provides guidance and support to the following projects implemented by the Shimizu Construction Subcontractors’ Accident Prevention Council.

- Research on occupational health and safety and conducting health and safety training

- Research on health and safety regarding machinery, tools, and other equipment used in construction

- Investigation into the cause of accidents and implementation of relevant preventative measures

- Compliance with labor laws and regulations, and miscellaneous matters regarding health and safety

- Coordination of health and safety related measures with suppliers and subcontractors

- Provision of guidance on health and safety through regular job site patrols

- Surveying job site environments and implementing policies and measures

- Planning and executing various events related to occupational health and safety campaigns

- Other actions necessary to achieve the goals of the Construction Accident Prevention Council