UCHINO SEISAKUSHO Co., Ltd. AKIRUNO FACTORY is a precision machinery plant manufacturing special ordered gears for new automobiles and motor sports vehicles.

To start this project, the architectural designer temporarily joined the company and experienced the same atmosphere and time with the employees. By this experience, two main themes, “the pleasant workplace for employees” and “the environment supporting the highest quality manufacturing”, were set as goals of this project.

Next, environmental simulations were applied to understand the impact of environmental factors (light and heat) on employees and the machines. By visualizing such environmental factors, feedbacks were made on designs. Following show the methods used in the environmental simulations.

UCHINO SEISAKUSHO Co., Ltd.

AKIRUNO FACTORY

Precision machinery plant of the highest quality product

For planning the plant of the world’s leading technologies, we focused on two main themes: “the pleasant workplace for employees” and “the environment supporting the highest quality manufacturing”. For realizing these two themes, digital designing is used in the planning process.

- Site

- : Akiruno City, Tokyo

- Site area

- : 3404.27㎡

- Total floor area

- : 1990.49㎡(Main building)

151.28㎡(Annex) - No of floors

- : 2 floors above ground

PH 1 floor - Structure

- : S structure

Applying computational design for the proposal of

“the pleasant workplace for employees” and

“the environment supporting the highest quality manufacturing”

Visualizing Light and Heat

Manufacturing area

Visualizing light and thermal environment and

selecting the best-balanced plan

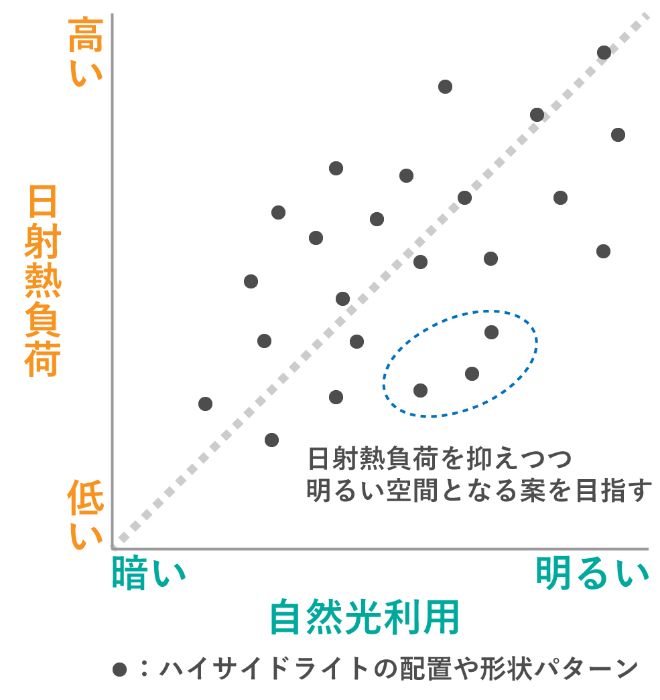

Since this plant process highly confidential products, it was difficult to place windows on outer walls of manufacturing area, therefore employees were having hard time feeling the daylight. Also, in order to maintain the quality of the precision machineries in manufacturing area, it was necessary to precisely control airflows and thermal conditions. High side lights were planned on the ceiling to overcome the daylight problem and also machine rooms were designed on the outer rim of the building, creating double wall structure to decrease the heat loads of the outer skin and enabling employees to feel the daylight.

On the other hand, by planning the high side lights, there were some possibilities of deteriorating the indoor thermal environment. Therefore, light and thermal environments were visualized by simulations, which led designers to select the best-balanced plan which is both human and machine friendly.

Cross Section of manufacturing area

Bright and pleasant light environment by daylight

Numerous patterns of positions and shapes of the high side lights were considered to maximize the daylight into the room as well as not to guide the direct light to the floor surface. In order to seek the best solution, the analyses were conducted in two steps:

Annual Sunlight paths

1. Visualization of the direct light

First, sunlight paths of every hour were analyzed for every pattern of the high side light to check the hours of direct light coming into the building.

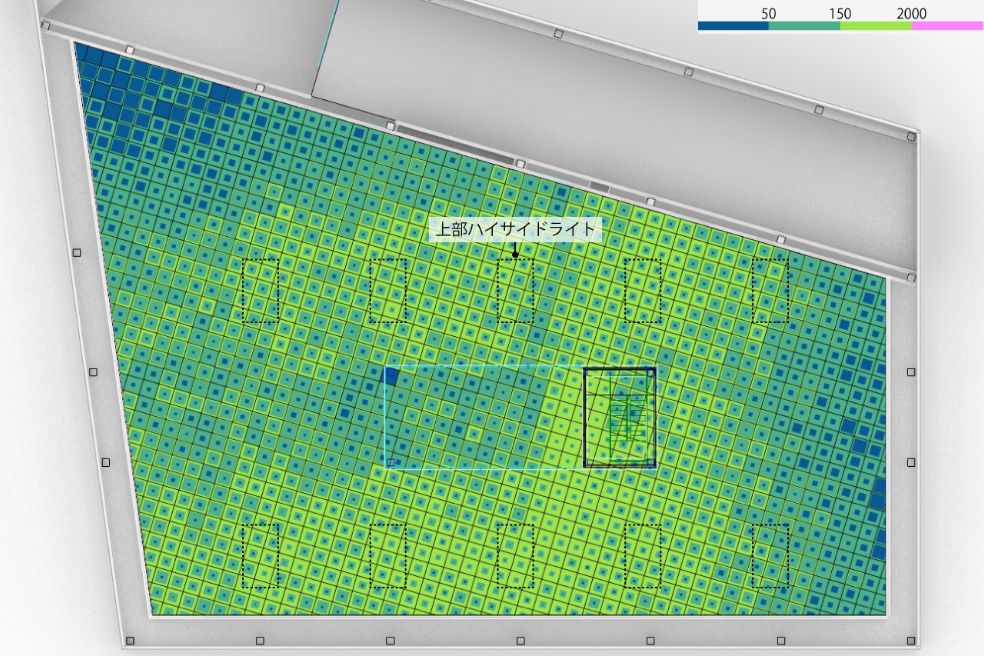

Simulation result of annual illuminance

2. Daylight availability

Next, annual Illuminance was analyzed to design the details. By visualizing the ratio of hours achieving the target illuminance (300~2000lux) annually (from 8:00~17:00), designers were able to seek the best plan which would maximize the daylight led into the building.

Thermal environment considering the comfort of employees and

precision of machinery

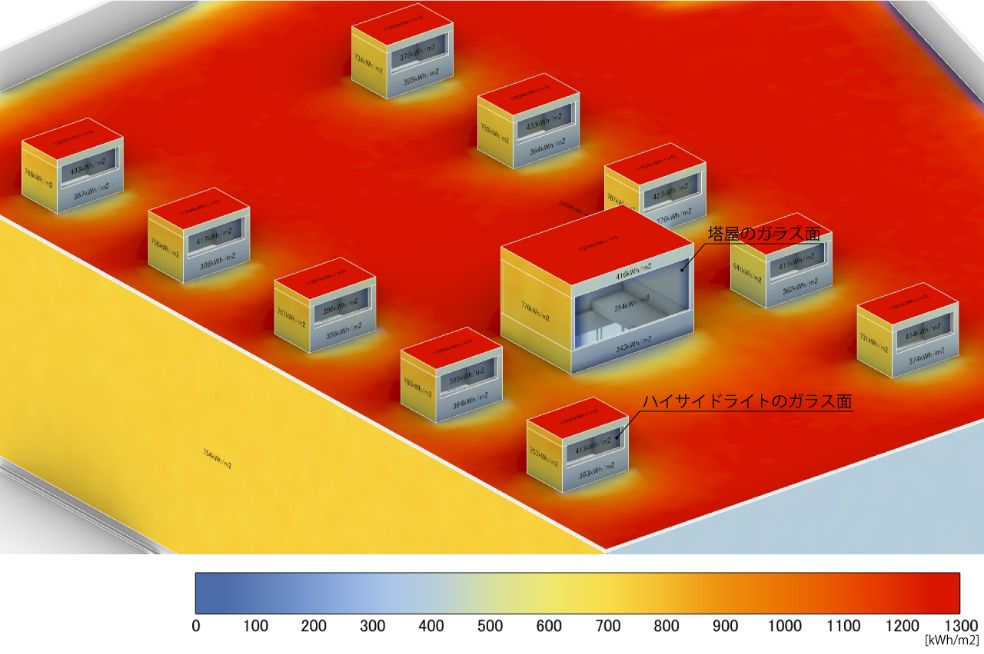

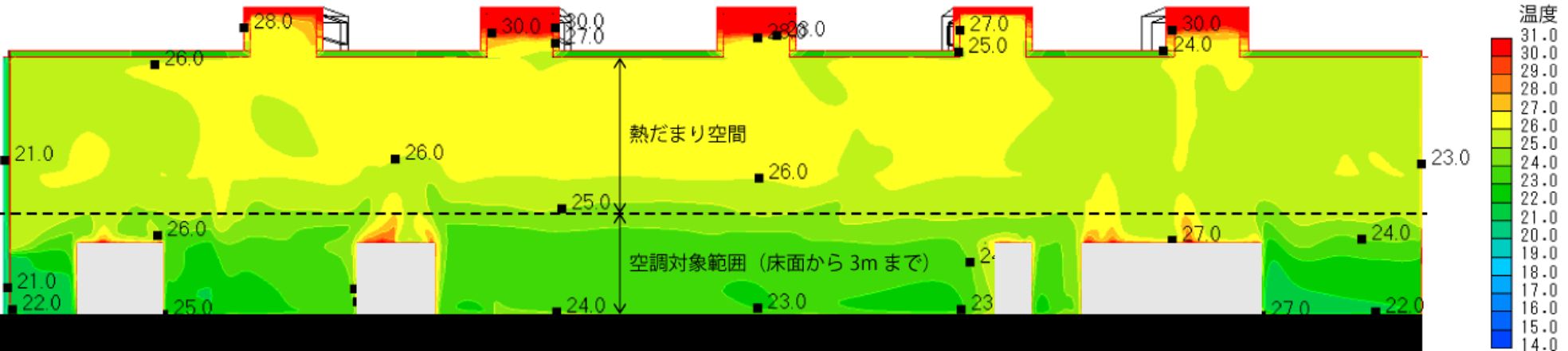

By calculating the annual sun radiation on the glass surface of the high side light, the heat load of the building was visualized. The heat generated by machines was taken into account and the simulation was conducted to check the temperature distribution. This was to check the design meets the requirements of the thermal condition in the area of which employees would use.

Displacement ventilation (a system which slowly distributes the conditioned fresh air from the floor) is applied. The fresh air, air velocity at approximately 0.5 m/s, is introduced from the outer rim of the plan. This enables the employees not feel the discomfort by the air flows and also not affect the precision of machineries.

Annual sun radiation of high side light and rooftop

Evaluation of displacement ventilation by thermal simuation(cross section)

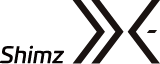

Combining the analysis of light and thermal environment

Results of light and thermal environment simulation were combined, and the best shape and position of high side lights were confirmed. First, size of the high side light openings was set as the parameter to auto-generate mass patterns of the design. Then the simulation of annual illuminance and annual sun radiation was conducted for every pattern. Shimz Explorer was used to determine the best solution from this mass design patterns. Designers compared the simulation results and narrowed the patterns. This method enabled to select the best-balanced design of both light and thermal environment.

Simulation of annual illuminance and narrowing method of results using Shimz Explorer

*1 Shimz Explorer:Optimization tool*2 using Brute Force Method.(Development in cooperation with:Thornton Tomasetti / Core Studio、Algorithm Design Lab.inc.)

*2 A method of narrowing down the solution by setting multiple target values from the vast number of parametrically generated possibilities.

Softly Delivering the Light

Entrance hall

Dramatic display area

by daylight

Daylight from the top light softly and dramatically illuminates the display area of the entrance where racing cars and special gear products are displayed and welcomes the visitors.

The top light and the louvers deliver daylight softly into the space, and also act as a heat reservoir which would achieve both light and thermal environment comfort.

Display area of the entrance hall for gear products

Understanding the brightness and Illuminance distribution

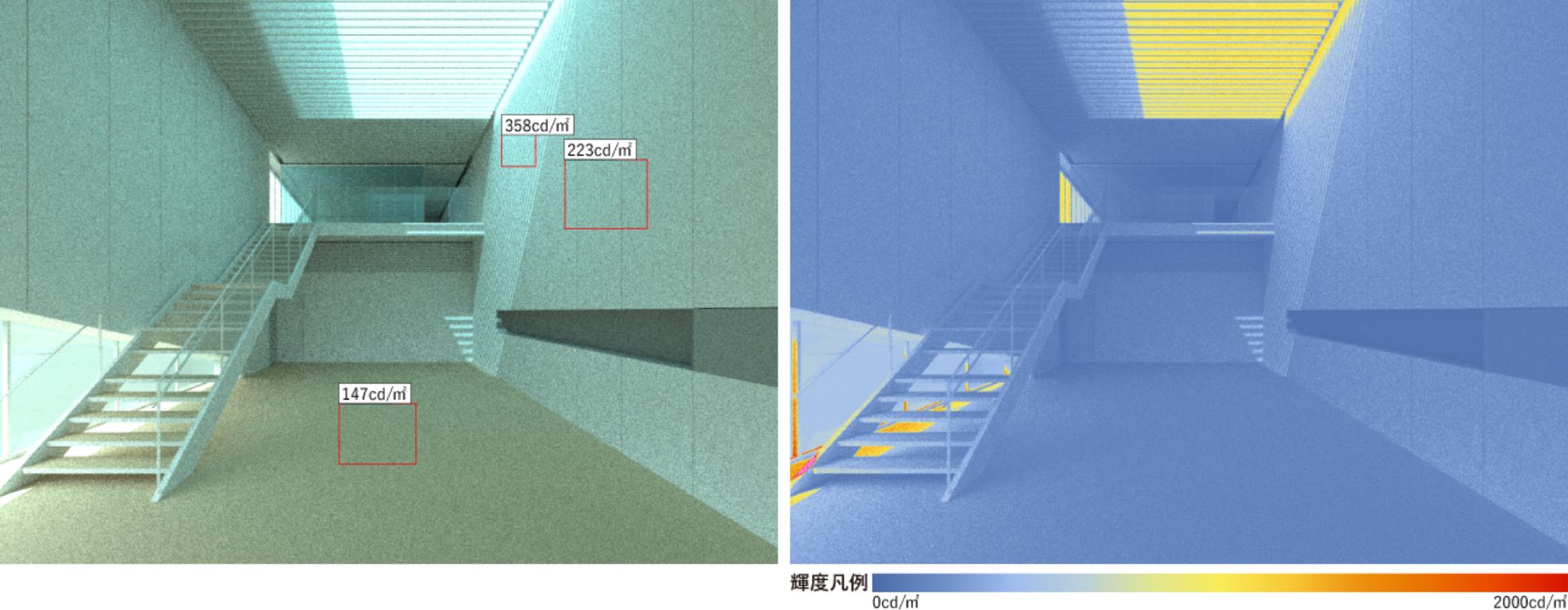

For the top light, horizontal louvers are placed to diffuse light which leads the entrance hall to be a brighter space. The brightness distribution map (specific date and time) was evaluated to confirm the glare by the top light.

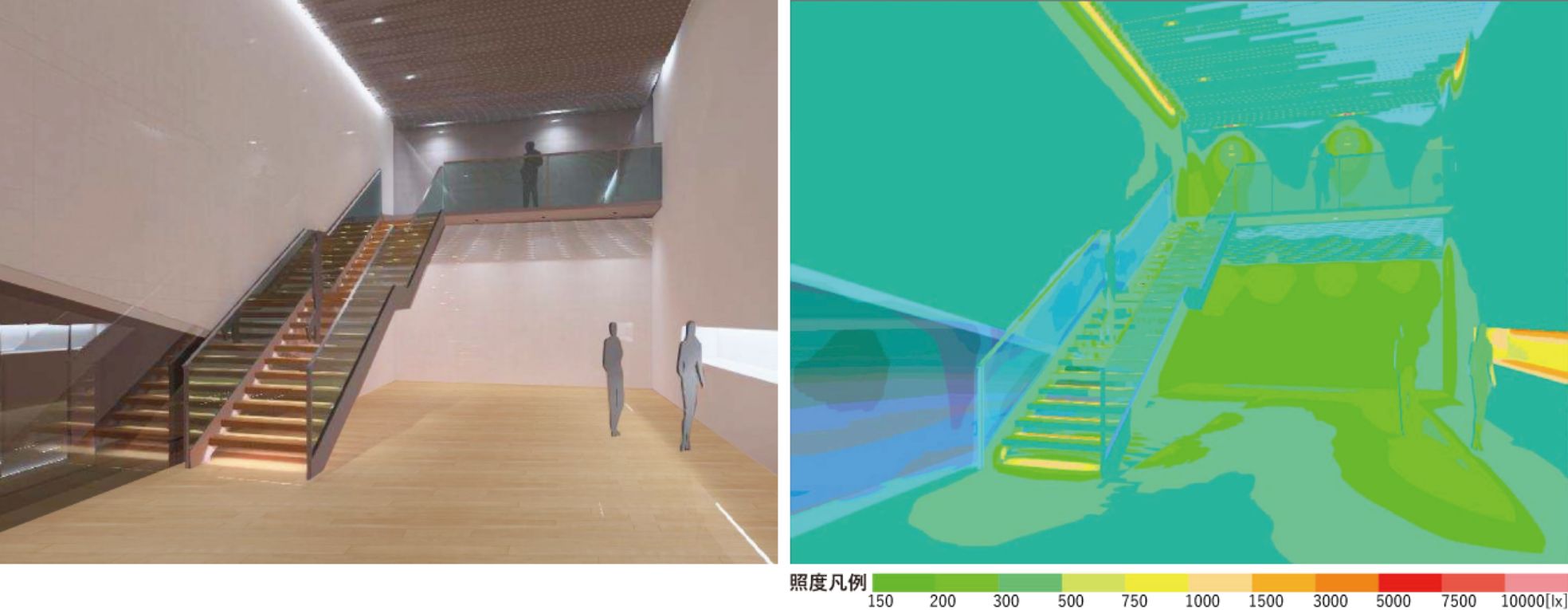

The entrance hall is lightened mainly by the indirect lighting installed between the footsteps of stairs and the ceiling louvers. Illuminance distribution map was used to evaluate the illuminance of the nighttime and guarantee the appropriate illuminance.

【Daytime】

Left: rendered image of brightness by daylight;

Right: brightness distibution map

【Nighttime】

Left: rendered image of brightness by lighting;

Right: illumance distibution map

Architectual Design

Michihito Soda

Architectual Design

Shunpei Fukamachi

Architectual Design

Yuki Endo

Mechanical Engineer

Yuki Tsutsumi

Electrical Engineer

Yuta Yamada

Although this precision machinery plant required strict environmental performances, we were able to design a workplace not only guarantees such requirements, but also the pleasant environment for employees where they can feel daylight and comfortably work. It is not easy for clients to imagine the light and thermal environments by blueprint. By using visualized images and quantitative results by simulations, we were able to reach to a consensus smoothly. We believe that making the most use of environmental simulation not only improves the environmental quality of the building, but also helps the communication between clients and designers by visualizing non-visual information.