May 13, 2016

The Future of CLT, a Construction Material Offering Superior Thermal Insulation that Can be Constructed Quickly

On October 1, 2010, the Act for Promotion of Use of Wood in Public Buildings was enacted. It was targeted at the proper management of forests to developing healthy, sustainable forests by ensuring the use of wood. The law requires considering the use of wood in low-rise public buildings that do not require fire-resistance, in principle. The ripple effects from this are expected to reach the private building in the future. We therefore asked Yasushi Miyatake from the Japan Cross Laminated Timber Association about the specific characteristics of CLT and how it is being used. CLT (Cross-Laminated Timber) has been recently been drawing interest as a new wood construction material.

CLT, which consists of multiple layers of cross-laminated boards, has superior properties

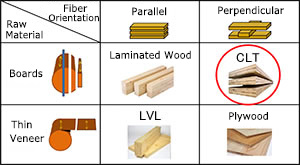

To give a short description of various construction materials, they are products made from board, or made from laminating a thin veneer sheets or wood chips in a cross-wise or parallel direction, or made from fiber like hardboard. The product that is currently drawing interest from among those is CLT, a wood material made of sawn boards cross-laminated onto each other in alternating perpendicular directions. Incidentally, CLT consists of sawn boards that are cross-laminated in alternating directions, while laminated wood is laminated parallel to the grain, LVL (Laminated Veneer Lumber) consists of a thin veneer sheets laminated onto board in a parallel fashion, and plywood is laminated in a cross-wise fashion.

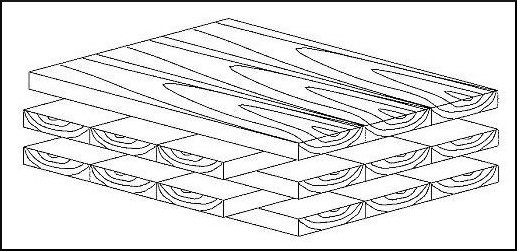

CLT is produced by gluing lamina (the smallest sawn boards that make up cross-laminated timber) together in a row, then gluing boards in the next layer together perpendicular to that, and repeating this process. It has the following four characteristics as a material:

Created by Yasushi Miyatake, Team Leader, Forestry and Forest Products Research Institute and Takafumi Nakagawa, Head of Research, National Institute for Land and Infrastructure Management (NILIM), Ministry of Land, Infrastructure, Transport and Tourism

(1)Wooden boards of differing widths and thicknesses can be used.

Since boards are lined up in a row, it is not necessary for them to be of the same width. However, in Japan, where the use of CLT has not yet become prevalent, it is currently produced using boards of the same width.

(2)High dimensional stability can be obtained.

Wood materials have a structure similar to bundled straw, and the cross section will swell if water intrudes. CLT offers better dimensional stability because it is cross-laminated.

(3)It provides high degree of insulation, sound insulation and fire-resistance.

Wood materials are known for their many air layers. CLT, in particular, ranges in thickness from 50 mm to 250 mm, is extremely effective resisting fire and providing thermal and sound insulation compared to other wood materials.

(4)The use of large panels offers a high degree of earthquake resistance.

Wood materials do not provide very good adhesion efficiency compared to steel, but the use of large panels increases rigidity and enables CLT to withstand the force from earthquakes.

CLT:Cross Laminated Timber

A term used to describe panels produced by laminating together multiple layers of boards with each layer aligned perpendicular (cross-wise) to the layer beneath it, and to the method of construction.

Construction is quick and safe, and joining is also simple

The method used to produce CLT is also called CLT. The CLT construction method also has the following characteristics:

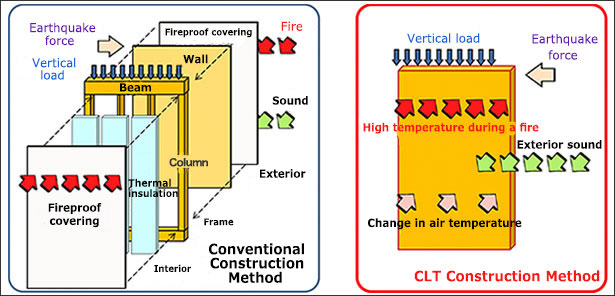

(1)Superior thermal insulation, heat resistance, and sound insulation can be achieved with CLT alone

The characteristics are the same as those described above for CLT as a material. The thermal conductivity of wood is roughly one-twelfth that of concrete and one-thousandth that of steel. CLT is a thick block of such wood materials. Structures up to now have been built by inserting thermal insulation material into the walls and applying a fire-resistant covering, with each material serving a specific role.

However, CLT is highly valued overseas as extremely cost efficient and process efficient because it is capable of providing thermal insulation, fire resistance, and sound insulation on its own.

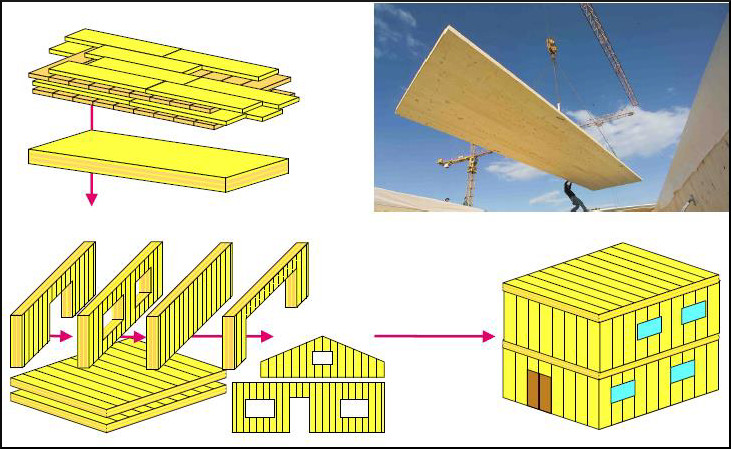

(2)Quick Construction

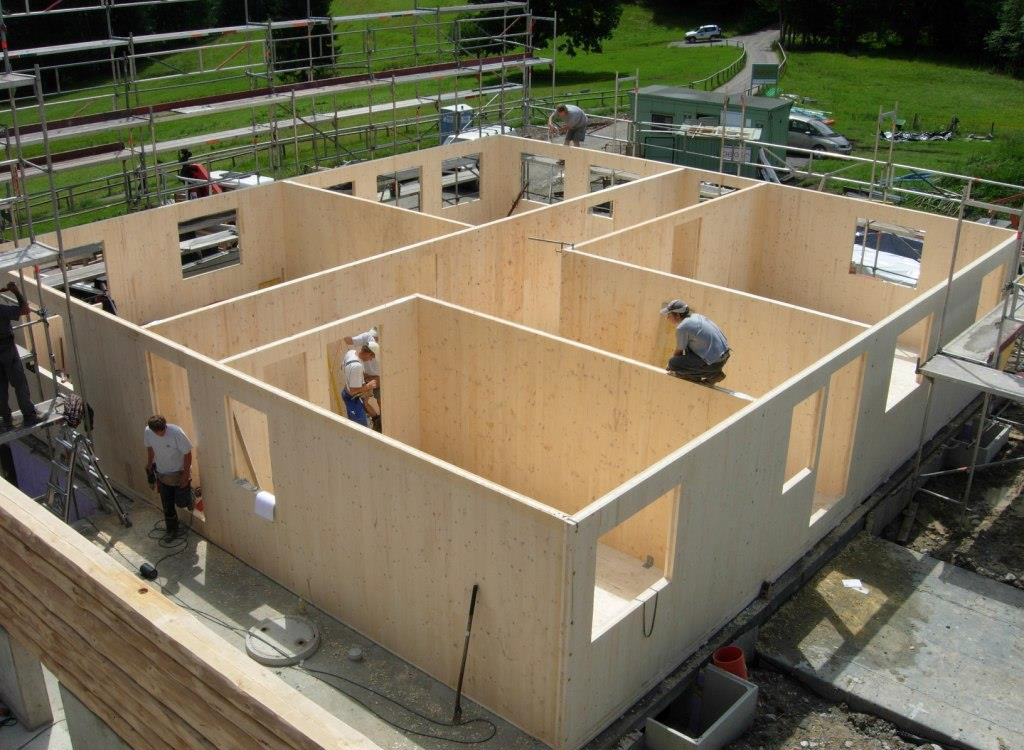

The large panels are prefabricated at a plant and construct at on site. The necessary shapes for apertures, piping and facilities are delivered pre-cut so they only need to erect at the construction site. Metaphorically, it is similar to building a plastic model, and does not require the expert construction skills of a carpenter or a scaffold builder. Moreover, it can be constructed quickly and safely, and does not generate much waste at the construction site.。

(3)Joining is simple

The CLT construction method was developed in Europe in the middle of 1990s. The use of CLT in Europe enables the construction of 6-story buildings with just screws and hardware to join the CLT. Tensile bolts are used in Japan due to the many earthquakes, but the basic concept is the same, and the hardware is very simple.

CTL is widely used in Europe under the concept of the right material in the right place

CLT is currently used in various kinds of buildings overseas, from six to ten-story condominiums, to typical homes, medium to large-sized commercial facilities, and industrial facilities. Despite that, use of CLT is not being actively promoted in Europe. Since wood actually swells and warps when it gets wet, this can cause rot so you do not see much wood construction overseas. The wood is basically covered with a different exterior material and buildings are constructed so that the wood does not show. In other words, the focus in the use of CLT overseas is on how to use the characteristics of the component materials and construction method.

For example, 8,000m3 of CLT panels and 3,500m3 of laminated wood were used in a large shopping center built on the outskirts of Vienna, Austria in the fall of 2012, for a total of 11,500m3 of wood materials. However, the structure for the first and second floors was built of steel and reinforced concrete, and wood was used for the roof. In other words, wood was perceived as a material that was lightweight compared to steel and reinforced concrete, and suited for use for roofing and panels, rather than floors. The right materials were used in the right places and this is a good example of use.

Mountain huts are another example where the superior workability is put to good use. A great deal of labor is involved in carrying materials to the construction site to build a mountain hut. Because CLT is lightweight, it can be brought in by helicopter. It is also precut, so it can be brought in by helicopter and then erected as is. This makes maximal use of the advantages of CLT. It is also used in combination construction methods in which the frame is erected using laminated wood for the columns and CLT for the floors. I think that using the characteristics of CLT in this manner will also lead to increased use in Japan in the future.

CLT is easy to process and is also suited for non-structural purposes

The first building constructed of CLT in Japan was the employee dormitory of Kochi Otoyo Sawmill Co., Ltd., which was completed in March 2014. Other buildings were subsequently built, including two residential complexes in Fukushima Prefecture built of locally produced lumber and a seminar house built of Japanese larch wood in Hokkaido. CLT is also being used to build exhibition halls, warehouses, model homes, temporary shops, bus stops, and other structures.

JAS (Japanese Agricultural Standards) were established for CLT in December 2013. Two companies will acquire JAS plant certification in June of next year, enabling them to ship JAS-certified products. I think the number of buildings built with CLT will increase if it becomes possible to use CLT as a structural material for buildings in the future, but standard specifications need to be established first, before the use of CLT for structural materials will spread. It is also necessary to work on technical issues such as improving construction technology, joining technology, and improving manufacturing, processing, and material performance.

It is also essential that non-structural use increase in addition to this. Large boards are used in CLT and the main lumber currently used is Japanese cedar so it is easy to process and is already used for book shelves, partitions, tables, other furniture, and toys. I would like to put more effort into increasing the use of CLT in the future so that it becomes a familiar material used in this manner in a wide variety of areas.

Japan Cross Laminated Timber Association

The Japan Cross Laminated Timber Association was established in January 2012 for the purposes of enabling the use of cross-laminated timber (CLT) as a construction material and to make it possible to use CLT in the construction of mid-rise and large buildings in the future. It has operated as a general incorporated association since April 2014. Meiken Lamwood Corporation, where Mr. Miyatake works, serves as the chair corporation for the association.

According to Mr. Miyatake, Meiken Lamwood Corporation is in the process of building a new plant for the mass production of CLT to facilitate the spread of CLT use in Japan. The plan will have a maximum annual production capacity of 50,000 m3, and the company is planning to produce 30,000 m3 a year. The largest size of CLT produced will be 3,000 mm wide × 300 mm thick × 12,000 mm long.g.

Examples of Non-structural Use of CLT