-

April 3, 2024IR News

-

April 01, 2024Update

-

March 5, 2024IR News

-

February 6, 2024News Release

-

January 19, 2024News Release

-

December 8, 2023News Release

-

November 13, 2023ESG News

-

September 4, 2023ESG News

-

November 4, 2022ESG News

Recommended Contents

The Shimizu Group is committed to creating value that is ahead of its time, through constant self-transformation,

challenging the ordinary, and co-creation with diverse business partners.

Through Smart Innovation, we aspire to contribute to a sustainable future where people can enjoy abundance and happiness.

Shimizu's Businesses

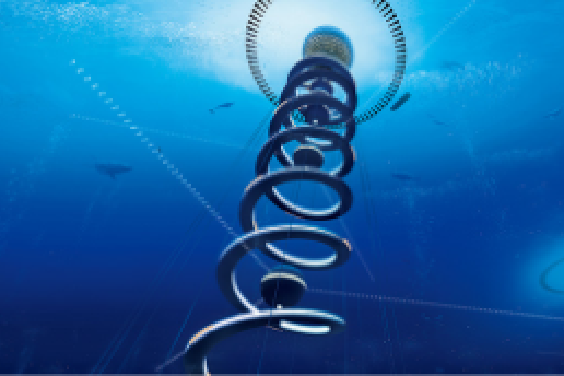

In addition to its core construction business (building construction, civil engineering, and overseas construction), Shimizu engages in four areas of non-construction business: The real estate development, engineering, LCV (Life Cycle Valuation), and frontier businesses.

Shimizu's approach

Investor Relations

Our website uses cookies.

You can change the cookie settings in your browser settings at any time.By using this website, you are agreeing with our Cookie Policy.