Building the Groundwork for Our Lives and Protecting Communities H&V Shield Method, World’s First Spiral Excavation Using Double Shield at Underground Tunnel Construction of Tachiaigawa River Trunk Sewer Stormwater Outlet Channel

Torrential rainfall has occurred with increasing frequency in recent years, causing rivers to overflow and flooding damage. As concerns over disaster prevention and mitigation increase, there are demands to build infrastructure that increases national resiliency and protects the safety and security of the public. Shimizu has been working on construction of a rainwater drainage canal along the Tachiaigawa River Trunk Sewer in Shinagawa-ku, Tokyo since 2016 to prevent flood damage and deterioration in water quality. Here we introduce Shimizu’s first-in-the-world challenge in spiral tunnel excavation using the H&V (horizontal and vertical) shield method.

To prevent flood damage and deterioration in water quality

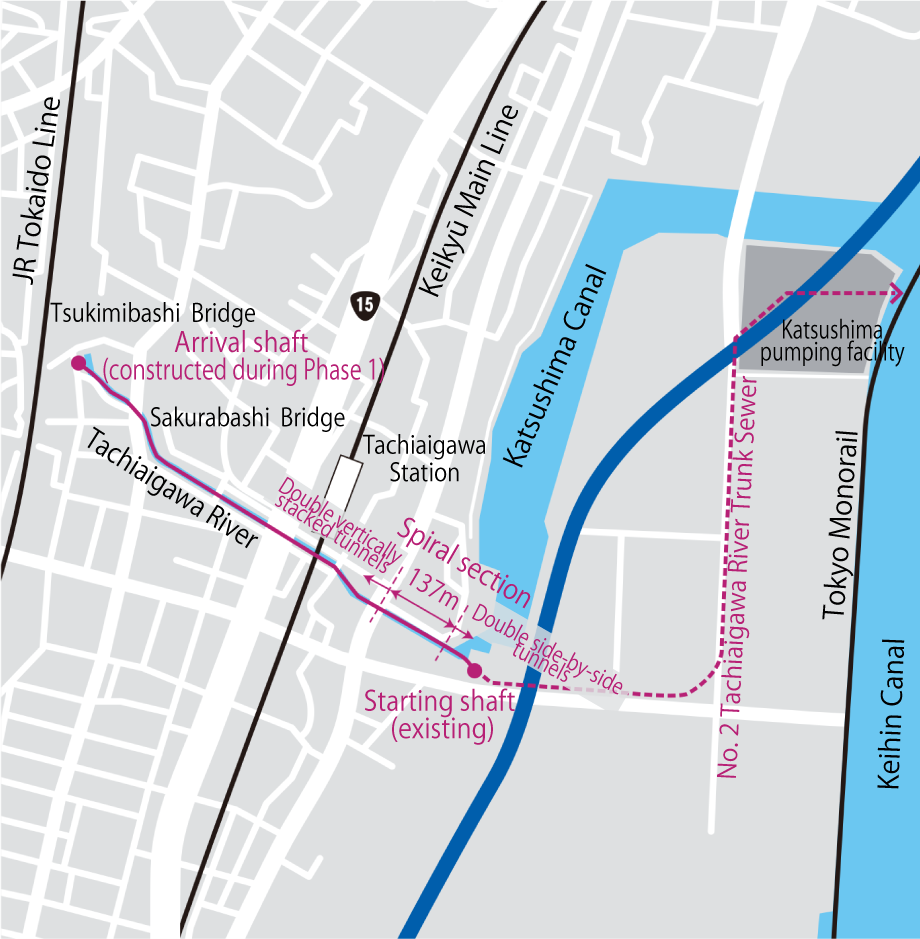

The Tachiaigawa River begins at Himonya in Meguro-ku and runs for about 7.4 km to pour into the Katsushima Canal around Higashi-Oi in Shinagawa-ku. As the river basin has become urbanized, most of the river has flowed through the underground trunk line(Tachiaigawa River Trunk Sewer), and only about 750 m of the downstream part flows above ground.

In its current form, the Tachiaigawa River connects with a combined sewer in the vicinity of Tsukimibashi Bridge. When a large amount of rain falls in the river basin, it drains a large volume of rainwater mixed with sewage water in a short period of time. On top of concerns over the massive flooding that would occur if the river overflowed, this also causes deterioration in the water quality and foul odors in the river and canal and improvement are urgent issue.

Our project involves construction of the Tachiaigawa River Trunk Sewer Stormwater Outlet Channel directly beneath the river from Tsukimibashi Bridge to the river outlet. The purpose of this project is to provide direct drainage of rainwater into the Keihin Canal via the existing No. 2 Tachiaigawa River Trunk Sewer.

Shield machine begins as double side-by-side and ends as double vertically

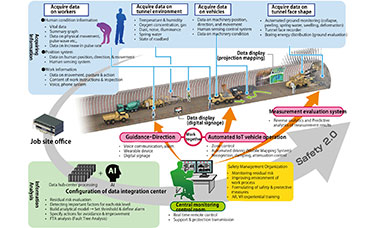

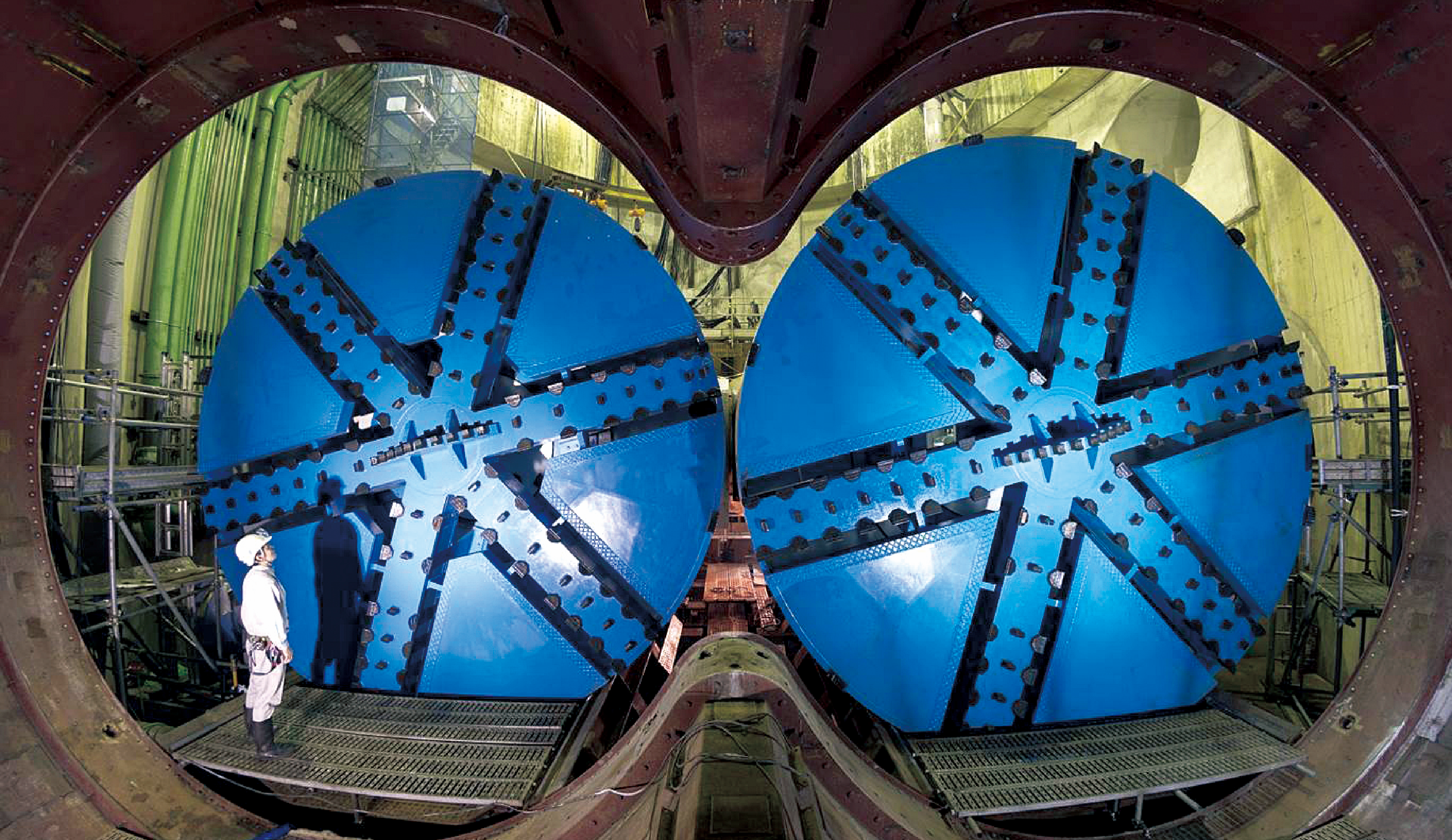

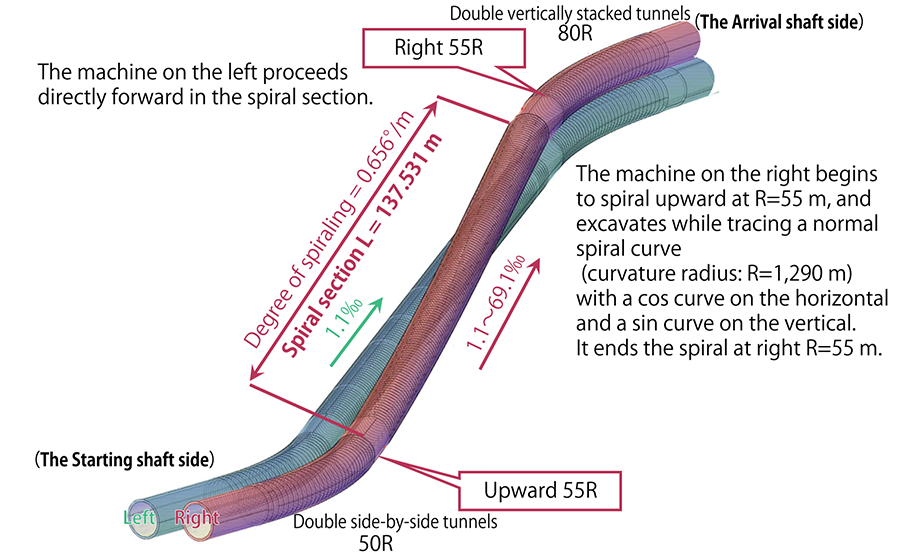

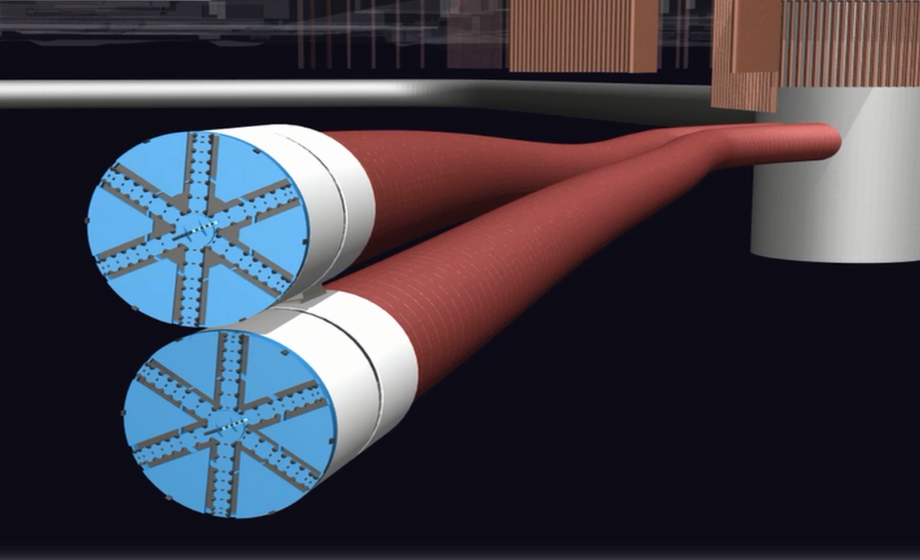

The space available for constructing the drainage canal had the constraints of being little vertical height at the river mouth where the starting shaft is located and narrow horizontal width at the S-curve in the middle, near Sakurabashi Bridge. This made it necessary to build two drainage canals with an inner diameter of 5 m (outer diameter of 5.7 m) to accommodate the drainage volume when raining (maintain the required drainage level) within those constraints. The method chosen to accomplish that was spiral excavation using the H&V* shield method. This method combines two shield machines that turn in a spiral while excavating tunnels. Using two machines once instead of one machine twice has the advantages that constructing two neighboring tunnels simultaneously, reducing the range of soil improvement, and requiring only one starting step. This was the world’s first attempt at constructing a spiral tunnel using this method.

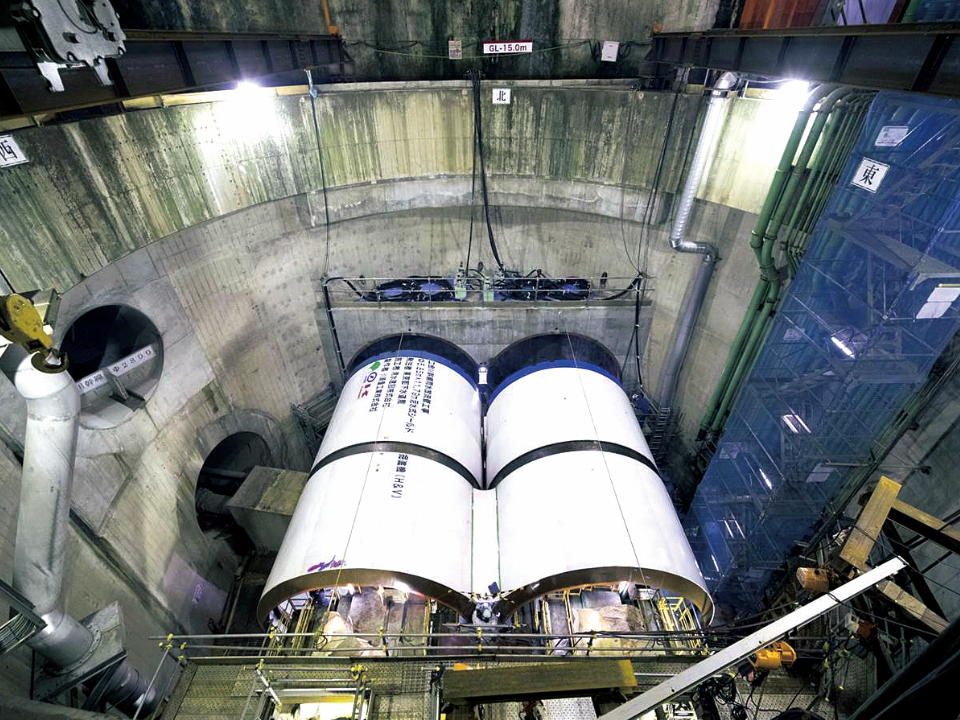

As shown in the image below, the double shield machines start side-by-side in an starting shaft at the river mouth. After excavating a sharp curve to the left, they begin spiral excavation. The shield machine on the left serves as the axis and the machine on the right rotates in an upward direction. After rotating 90 degrees roughly 137 m, they excavate vertically stacked tunnels for the remaining distance, which has horizontal space constraints, until they reach the arrival shaft.

※Horizontal & Vertical variation

Produced in 2017 by Bureau of Sewerage, Tokyo Metropolitan Government and Shimizu Corporation(4:01)

Shimizu devises new technology and achieving precision direction control

For the conjoined structure of the left and right shield machines, we have newly devised and adopted the rear body rotating-type joint method by pin joining. This makes it possible to excavate while precisely controlling the angle between each shield machine. Making the entire machine on the right side upward during spiral excavation makes it possible to obtain rotational force in an upward direction. This also enabled reduction in the 30 cm overbreak (the amount of rock or earth in excess excavation beyond planned extent)previously considered necessary to about 1 cm, and minimized the impact on the surrounding earth.

We build an excavation management system specifically, for the H&V shield method to monitor the positions of double shield machines and motion of the rotating section. Using this system makes real-time integrated management of the shield machines from a central control room, and precision direction control during excavation.

Completed Excavation with the combined skills of everyone involved

During the initial excavation, which began in February 2018, slurry water leaked in between the starting shaft wall and the machines, and made it impossible to maintain the necessary slurry pressure to retain the excavated face. Hironobu Ota, who was the construction manager commented, “As I watched staff members and workers laboring while covered in mud, I was painfully aware of my own insufficient skill in planning. I couldn’t sleep at night for a number of days running.” We overcame numerous obstacles and reached the end of September 2018 despite that.

Ota recollected, “The atmosphere during the morning meeting on the day scheduled completion of the spiral excavation was tense, and the determination of everyone to make the world’s first spiral excavation a success at any cost came through acutely. Immediately after I shouted 'Here we go on the final round!' in the tunnel on the left, I heard shouts from the tunnel on the right 'Here we go on the final round!' 'Whoohoo!'. Hearing that filled me with deep gratefulness for my co-workers who enabled us to get to this point and I was convinced that we would succeed.” The shield machines reached their destination in July 2019.

Received Outstanding Civil Engineering Achievement Award at Japan Society of Civil Engineers(JSCE)

In 2019, the spiral tunnel excavation using the H&V shield method received Outstanding Civil Engineering Award (Group 1) at Japan Society of Civil Engineers. It was highly acclaimed for the substantial contribution to advancing shield technology by establishing the rear body rotating-type joint method and other technologies which can be applied to construction of tunnels with complex line shapes.

It will be increasing to construct in complex underground spaces with severe constraints in the future. Shimizu will broaden the areas of application of this success and will continue to contribute to the advancement of infrastructure.

photo: Kenichi Komeiji

The information posted here is the current information on October 27, 2020.

Please be aware that this information may have changed by the time you view it.