July 11, 2017

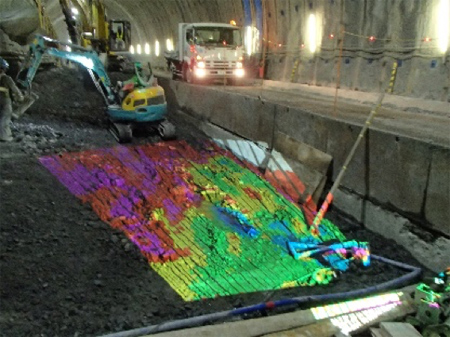

Shimizu Corporation (President: Kazuyuki Inoue) has developed a system for visualizing the status of excavation of the tunnel bottom for the invert using an integrated 3D scanner and projector to increase the safety and efficiency of invert (concrete tunnel bottom) construction in mountain tunnels. This system quantifies the degree to which the invert bottom is over- or under-excavated and is capable of projection mapping those numbers on the bottom surface in different colors. This enables workers to visually confirm the degree of over- or under-excavation while performing the work so they do not waste any time. It only takes about one minute to do the analysis and projection after the 3D shape data is obtained for the invert bottom surface.

When excavating the ground for mountain tunnels where the soil is of poor quality, a concrete base layer called an invert is laid in addition to steel arch supports at designated intervals along the tunnel roof to prevent tunnel deformation and collapse. The combination of the invert and supports protects the tunnel.

To construct the invert, the tunnel bottom is first excavated to create space for laying the concrete. If, however, the excavation is shallower than indicated on the design plan, the requisite quality cannot be obtained. If excavated too deeply, the excess sludge creates extra work to remove it, and this also increases the volume of concrete needed. For this reason, workers halt work every 10 to 15 minutes and take measurements to make sure the excavation is being performed according to the desired form, and repeatedly excavate places that are too shallow. The existing method of confirmation interferes with the excavation work, and if proceeding with the excavation work is assigned higher priority, this leads to more waste.

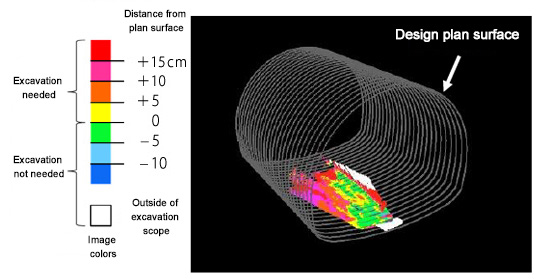

The newly developed system eliminates this issue completely. The system consists of a scanner that takes 3D measurements of the shape of the invert bottom and instantly determines the variance of the measurements from the design plan, analytical software that produces image data to project the variances on the bottom surface in different colors, and a projector to project the image data on the ground surface.

To use the system, the system unit consisting of the scanner and projector is first set up near the invert excavation site. 3D data on the shape of the invert bottom and surrounding area is obtained with the scanner and fed into the analytical software. The analytical software recognizes the 3D positioning data for the projector from the shape data obtained, instantly determines the variance between the 3D shape data and the design plan, and produces the imaging data for the projector to project on the invert bottom. The surface area that is projectable at one time is roughly 30 m2 (4 m wide and 7–8 m deep), and the projector can display the variance between the actual surface and the design plan in 5-centimeter increments.

This system enables workers to easily visualize the location and how much to excavate, so it enables remarkable improvement in excavation efficiency. It also eliminates the work involved in checking the bottom shape in locations where the ground is unstable, so it also improves safety. In the future, Shimizu will expand use of this system to more mountain tunnel job sites, and will also work on developing the technology to apply it to excavation work on the upper half of tunnels. Shimizu will be exhibiting this system in the technology exhibit corner of the 52nd Japan National Conference on Geotechnical Engineering, which will be held at the Nagoya Congress Center from Wednesday, July 12 to Friday, July 14.

<<For Reference>>

The information contained in this news release is the current information on the date of publication. Please be aware that this information may have changed by the time you view it. Please contact the company to inquire for further details.